Let’s be honest, running a traditional grid independence study feels like watching paint dry, but with more expensive hardware. You create a mesh, run the simulation, check the results. Then you refine the entire thing, run it again, and pray the key values don’t change much. It’s a tedious, resource-intensive process that can stall a project for days.

For years, this was just the cost of doing good engineering. But what if we could get the same, or even better, accuracy without the brute-force approach? That’s what we’re diving into here. This isn’t just another academic topic; it’s a core part of our deep dive into modern simulation techniques and a game-changer for practical CFD work. We’re talking about getting reliable results faster.

The Engineer’s Bottleneck: Why Traditional Grid Independence Studies Are Killing Your Project Timeline

I remember a heat exchanger project early in my career. We spent an entire weekend running three different mesh densities just to prove our grid was sufficient. That’s 72 hours of machine time, plus my time setting it up, just to get a single, validated data point. The whole team was waiting. That’s the classic bottleneck.

You’re burning through CPU hours, and if you’re on the cloud, you’re literally burning money. The worst part? You’re often over-refining huge sections of the domain where nothing interesting is happening—the far-field of an airfoil, or the bulk flow in a large pipe—just to capture a thin boundary layer or a small wake region accurately. It’s inefficient and, frankly, a bit archaic.

What is Adaptive Mesh Refinement (AMR)? The “Smart Meshing” Approach Explained

Think of AMR as a specialist, not a general laborer. Instead of refining the entire domain uniformly, AMR automatically identifies regions where the flow variables are changing rapidly—the areas with high error potential—and refines the mesh only there.

It starts with a coarse mesh, runs the solver for a few iterations, pauses, and then asks: “Where is the physics most complex?” Based on the answer, it splits the cells in those critical zones and then continues the simulation. It’s an intelligent, iterative process that puts computational effort exactly where it’s needed most. Simple as that.

How AMR Delivers Both Accuracy and Speed: The Core Mechanism

The magic behind AMR isn’t really magic; it’s just targeted logic. Teh process allows the simulation to evolve its own optimal mesh, focusing computational power on areas of high physical activity. This dynamic approach ensures that you’re not wasting resources on static, low-gradient regions of the flow field.

Step 1: Choosing the Right Refinement Indicators (Gradients, Vorticity, etc.)

This is the most critical decision you’ll make when setting up AMR. The “indicator” is the metric the solver uses to decide where to refine. Choosing the wrong one is like asking a navigator to use the wrong map. For an external aerodynamics case, you might refine based on the pressure gradient to capture shockwaves. For a combustion simulation, temperature gradients are your best friend.

In our CFD analysis services, we often see people using a single generic indicator for every problem. That’s a mistake. You have to tailor it to your specific physics:

- Aerodynamics: Pressure gradient, velocity gradient, or vorticity.

- Heat Transfer: Temperature gradient is a must.

- Multiphase Flows: Volume fraction gradient to capture the interface.

- Boundary Layers: Y+ adaption is crucial for getting wall shear stress right.

Step 2: Setting Intelligent Refinement Controls and Thresholds

Once you’ve chosen your indicator, you need to tell the solver when to refine. This is done by setting a threshold. If the gradient of your chosen variable (e.g., pressure) in a cell exceeds this value, the solver splits it. Setting this value is an art. Too low, and you’ll end up refining everything (an issue called over-refinement). Too high, and you’ll miss important physical phenomena.

A good starting point is to visualize the initial gradient fields and set a threshold that captures the top 10-15% of the highest-gradient cells. This entire process, by the way, is a prime candidate for automation, especially if you find yourself running similar cases repeatedly. We often use scripts for this, which is a topic we cover in our guide on automating your CFD workflow.

Implementing AMR in Ansys Fluent: A CFDSource Best-Practice Walkthrough

In Ansys Fluent, you can set up AMR directly in the solution controls. You’ll find the “Adaption” section where you can define your refinement criteria. You can choose to adapt based on cell registers, which you can create from gradients, Y+, or even custom field functions.

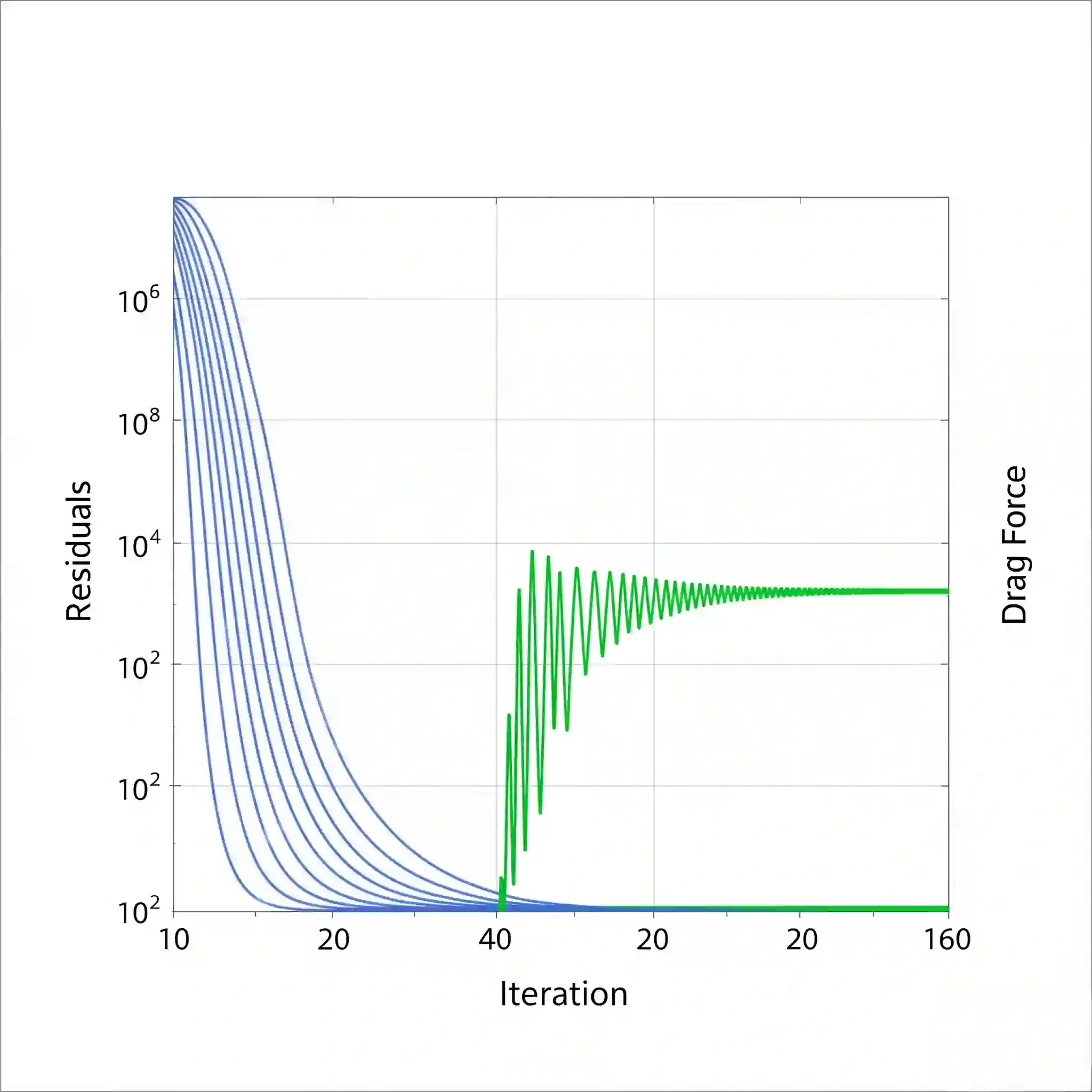

One pro tip: don’t just turn it on and let it run wild from the start. A better strategy is to run the simulation for a few hundred iterations on the base mesh to let the flow field develop. Then, pause the calculation, perform the mesh adaption, and continue the run. This prevents the mesh from adapting to the chaotic, unphysical noise of the initial solution startup. It’s a small detail, but it can save you a lot of trouble.

The Proof is in the Post-Processing: Visualizing the Efficiency of AMR

The results are often striking. 😮 When you visualize the final mesh, you won’t see a uniform grid. Instead, you’ll see dense clusters of tiny cells perfectly tracing shock diamonds in a supersonic jet exhaust, wrapping tightly around an airfoil’s leading edge and wake, or highlighting the flame front in a combustion chamber. The rest of the domain remains coarse and computationally cheap.

This targeted approach is completely different from methods like overset meshing, which solve the problem of complex motion by overlapping separate meshes. While powerful, AMR is focused purely on solution accuracy for a fixed domain. Seeing that final adapted mesh for the first time is an “aha!” moment where you realize how much computational power was being wasted before.

Quantifying the ROI: How Much Time and Computational Cost Can You Really Save?

Talk is cheap. Let’s look at some real-world numbers from a typical external aerodynamics case—calculating the drag on a vehicle. With a traditional approach, you might build three structured meshes. With AMR, you start with one coarse mesh and let it work.

The difference is not subtle.

| Metric | Traditional Grid Study | Adaptive Mesh Refinement (AMR) |

| Total Meshes Built | 3 (Coarse, Medium, Fine) | 1 (Coarse base mesh) |

| Final Cell Count | ~12 Million (Fine Mesh) | ~5 Million (Targeted Refinement) |

| Total CPU Hours | ~96 hours | ~28 hours |

| Engineer’s Hands-On Time | 4-6 hours (Meshing + Setup) | 1 hour (Initial Setup) |

That’s a ~70% reduction in compute time. For leading CFD analysis companies, this isn’t just a saving; it’s a competitive advantage. It means more design iterations, faster problem-solving, and a quicker path to market for your product.

Common Pitfalls in AMR: Lessons Learned from Our Industrial CFD Projects

Using AMR feels like a superpower, but it’s easy to get things wrong if you’re not careful. We’ve made some of these mistakes ourselves over the years, and they can be costly.

The Danger of Over-Refinement: When Your “Smart” Mesh Becomes Inefficient

I once saw a simulation where the AMR criteria were too sensitive. The solver started refining based on tiny numerical ripples in the flow field, not actual physics. The cell count exploded from 2 million to 20 million in an hour, and teh simulation ground to a halt. The “smart” mesh became dumber and slower than a brute-force fine mesh.

The lesson? Always set a maximum cell count or refinement level as a safety net. And start with a less aggressive refinement threshold until you understand how the solution behaves.

Why Poor Indicator Selection Leads to Inaccurate Results

This one is more subtle but just as dangerous. On a complex electronics cooling project, the team adapted the mesh based only on velocity gradients to capture the fan jets. The flow field looked perfect. But the simulation failed to capture a critical thermal hotspot on a chip because the temperature gradients in that slow-moving region were completely ignored.

Your results are only as good as the question you ask. If you don’t tell the solver to look for thermal gradients, it won’t. This is why for some highly coupled physics, you may even need to write custom UDFs to guide the refinement based on a combined, custom metric. It’s an advanced move, but sometimes necessary.

Is AMR a Silver Bullet? A Framework for Deciding When to Use It

Look, AMR is fantastic, but it’s not the right tool for every single job. It excels in steady-state problems or transients where the high-activity zones don’t move drastically.

But what about a missile stage separation or a valve opening and closing? In those cases, the mesh needs to handle large, rigid body motion. That’s a situation where you should be looking at other specialized techniques. For instance, our guide on simulating geometries with overset mesh covers a much better approach for those kinds of problems. AMR is a scalpel; don’t try to use it like a sledgehammer.

How CFDSource Leverages Advanced Meshing Strategies to Accelerate Your R&D Cycle

For us, AMR isn’t just a standalone feature; it’s part of a bigger toolkit. A truly optimized workflow might start with an AMR-driven simulation to identify key areas of sensitivity on a design. Then, we can feed that information directly into a more advanced process, like using an adjoint solver for true shape optimization.

By combining these intelligent methods, we move beyond simply analyzing a design to automatically evolving it. We build workflows that don’t just give you an answer, but help you find the best answer in a fraction of the time. That’s the core philosophy behind our CFD consulting service.

Your Pre-Simulation Checklist for a Successful AMR Implementation

Before you click “run,” go through this quick mental checklist. It could save you hours of wasted simulation time.

- Objective First: What single result is most critical (e.g., drag, peak temperature, pressure drop)?

- Indicator Match: Does your refinement indicator directly reflect that critical result?

- Baseline Run: Have you run the coarse mesh for a bit to establish a sensible flow field first?

- Thresholds Set?: Have you set both a refinement threshold AND a max cell limit?

- Monitor: Do you have a plan to check the cell count and solution monitors periodically?

Conclusion: Evolve Your Meshing Strategy, Accelerate Your Innovation

The old way of meshing still has its place, but it shouldn’t be your default. Tools like AMR are fundamental to modern engineering because they directly address the biggest constraints we all face: time and computational budget. By letting the physics guide the mesh, you focus your resources where they have the most impact. Mastering techniques like achieving grid independence with AMR is no longer a luxury; it’s essential for staying competitive.

Need an Expert Eye on Your Meshing Strategy?

Take a look at your current project. How many CPU-hours are being spent on regions of the mesh that are essentially doing nothing? By adopting a more adaptive approach, you not only save resources but also build deeper confidence in your results, freeing up your team to focus on the real engineering challenges.