Introduction: Why Your CFD Simulation is Failing (And How This Guide Makes You Think Like an Expert)

Let’s be honest. You’ve spent hours setting up a simulation. You hit “run,” and what happens? Either the residuals shoot to the moon, or you get results that make absolutely no physical sense. A hot surface that’s somehow cooling down? We’ve all been there. After over 15 years in this field, I’ve seen that the difference between a successful simulation and a failed one often comes down to a few fundamental oversights. This isn’t just a list of errors; it’s a guide to understanding the why behind them.

This guide will walk you through the most common beginner mistakes in CFD simulations, drawing from real-world project experience. Before we dive in, if you’re looking for a comprehensive overview of the entire field, our Ultimate Guide to Computational Fluid Dynamics is the perfect place to start. Now, let’s fix that simulation.

Mistake #1: Starting with Flawed Geometry (The “Garbage In, Garbage Out” Principle)

You’d be shocked how many complex simulation problems trace back to a simple, dirty CAD model. People get excited to jump into the meshing and physics, but they forget that the solver doesn’t care about your design intent; it only sees the surfaces you give it. Tiny gaps, sliver faces, or unnecessary features like screw threads can create impossibly small mesh cells that will kill your simulation before it even starts.

I once lost nearly two days trying to mesh a complex heat exchanger for a client. The problem? A tiny, invisible overlapping surface deep inside the assembly that our CAD guy missed. It was a nightmare to find.

- The Pro Fix: Why Geometry Cleanup in SpaceClaim or DesignModeler isn’t optional, its essential for a stable mesh.

Before you even think about meshing, open your model in a dedicated geometry tool. Use the repair functions to find and fix issues like gaps, intersections, and duplicate edges. Simplify your model by removing any feature that has no significant impact on the fluid flow—things like small fillets, logos, or bolt holes. A few minutes of cleaning here will save you hours of frustration later. Trust me.

Mistake #2: Underestimating the Mesh (The Foundation of Every Accurate Simulation)

Your results are only as good as your mesh. Period. Treating meshing as just a button-click process is one of the biggest beginner mistakes in CFD. The solver calculates equations on every single cell, so if those cells are distorted and poorly shaped, you’re feeding it bad information from the very beginning.

- Pitfall 2a: Ignoring Key Mesh Quality Metrics (Skewness & Orthogonality)

Don’t just look at the cell count. You need to check the mesh quality. The most critical metric is Skewness. A highly skewed cell (think of a diamond shape instead of a square) is terrible for numerical stability. As a rule of thumb, for most solvers like Fluent, you should aim for a maximum skewness below 0.85. Anything above 0.95 is asking for trouble. Always check your mesh quality report before moving on. - Pitfall 2b: Neglecting the Boundary Layer (How to correctly use inflation layers and target the right y+ value for your turbulence model).

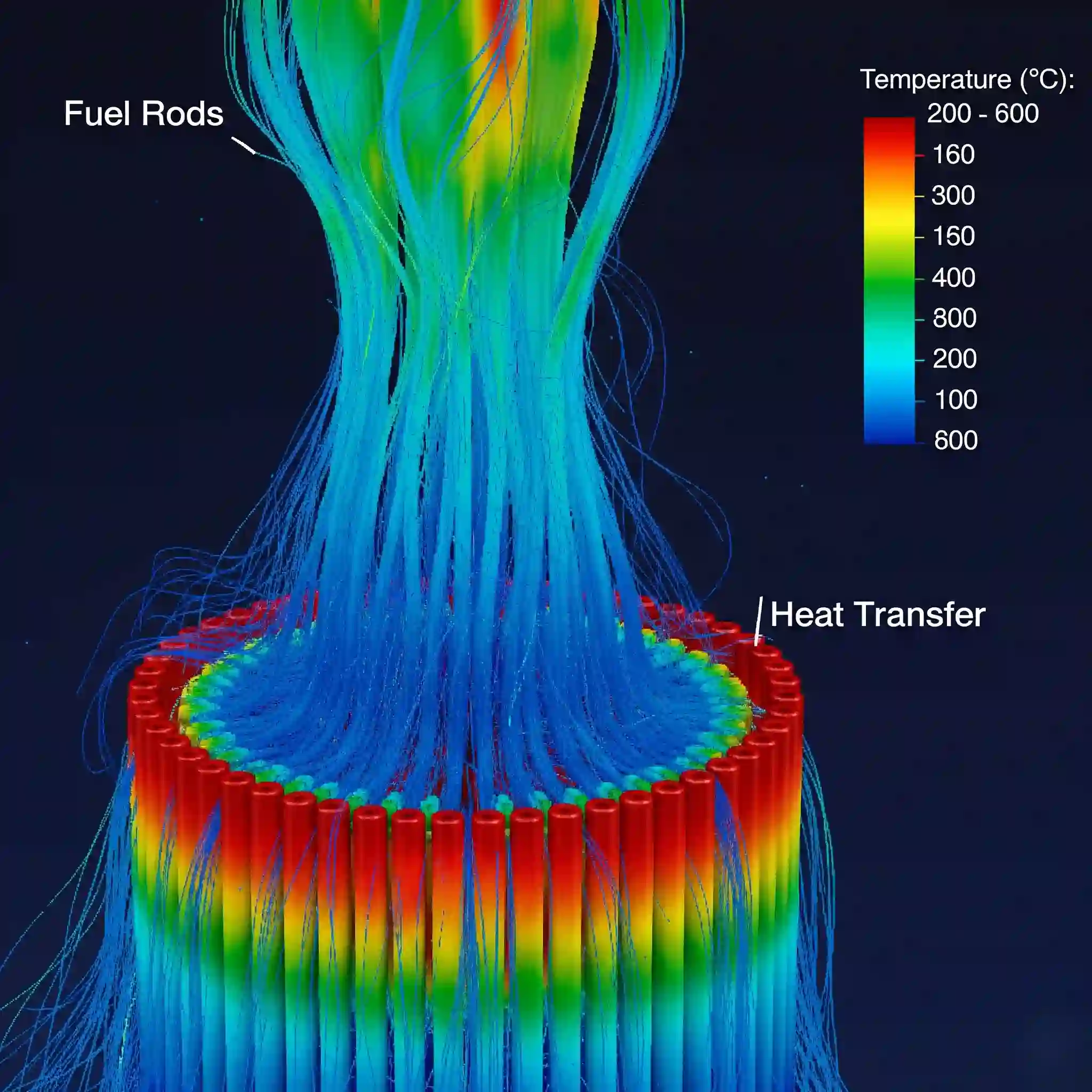

If you’re dealing with walls—which is almost every simulation—you absolutely need to resolve the boundary layer. This is where all the interesting physics of drag and heat transfer happens. Just using a generic tetrahedral mesh right up to the wall won’t capture it. You must use inflation layers (or prism layers) to create thin, structured cells stacked against the wall. The goal is to get your y+ value in the right range for your chosen turbulence model (e.g., y+ ~1 for k-ω SST). Understanding this is fundamental to how the finite volume method works accurately.

Mistake #3: Applying Incorrect Boundary Conditions (Defining a Problem That Isn’t Real)

This one sounds obvious, but it happens all the time. You can have a perfect geometry and a flawless mesh, but if you tell the solver that air is entering through a solid wall, your results will be meaningless. It’s critical to step back from the software and think about the actual physics of your problem. 🤔

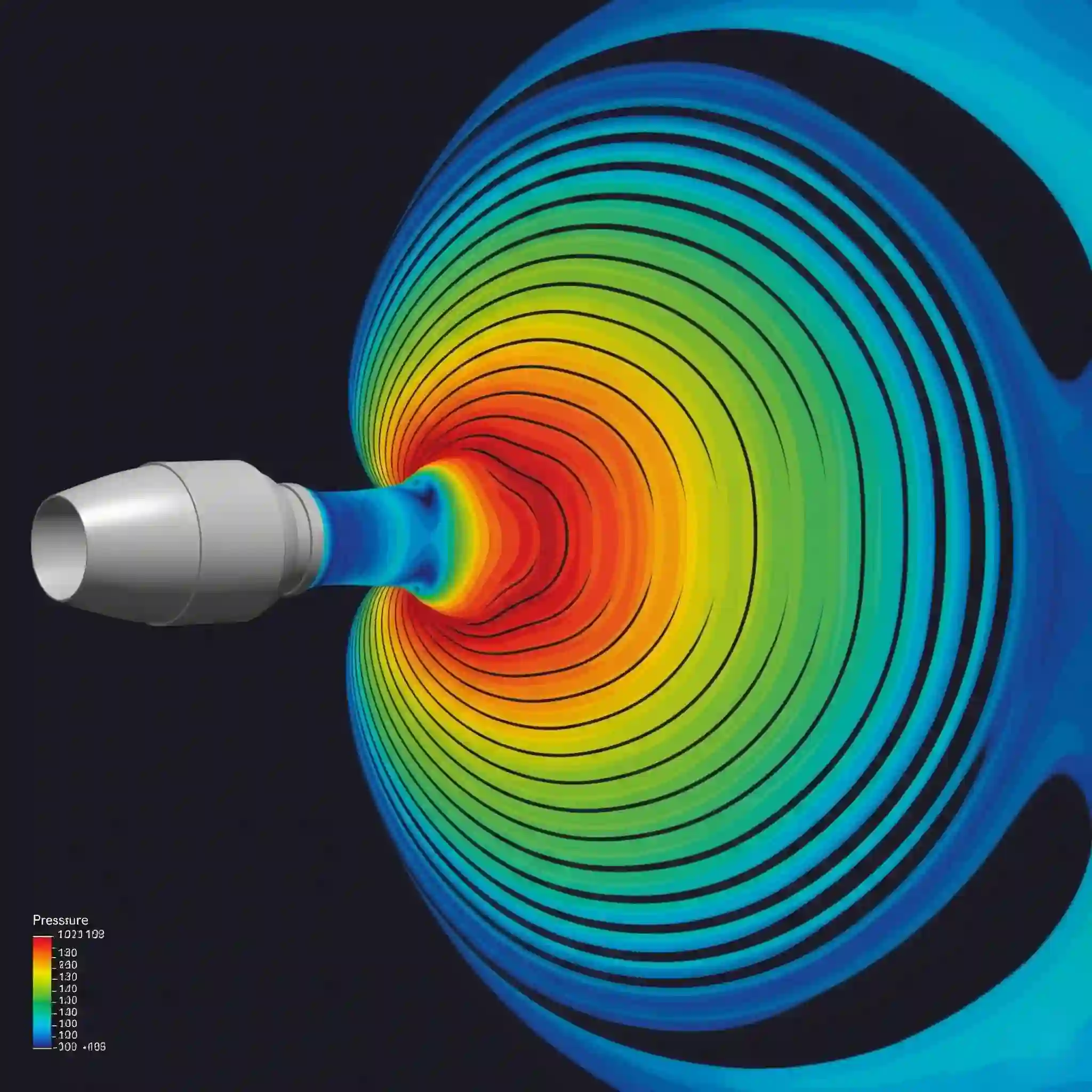

What is really happening at each boundary of your domain? Is it a pressure inlet or a velocity inlet? What’s the difference? For an outlet, is it a zero-pressure condition, or is there a fan creating a pressure jump? Defining these incorrectly means you’re not simulating your problem; you’re simulating a different one entirely. A common error is using a “pressure outlet” at an enclosed inlet, which can lead to reverse flow and immediate divergence.

Mistake #4: Choosing the Wrong Physics (Why CFDSource Prioritizes Turbulence Model Selection)

The “Physics” section in your CFD software is not a buffet where you can pick and choose randomly. Every model represents a set of mathematical assumptions about the real world. The most common pitfall here is turbulence modeling. Not all turbulence models are created equal, and simply using the default k-epsilon model for every single problem is a recipe for inaccurate results.

This choice is so critical that it’s often the first major decision point in our projects. If you’re struggling with this, engaging a Fluid Dynamics Consultant can clarify the best path forward for your specific industrial application.

- A Quick Guide: When to use k-epsilon vs. k-omega SST for industrial applications.

Here’s a quick, battle-tested cheat sheet from our experience:- Standard k-epsilon: Use it for fully developed, turbulent flows far from walls. Think of airflow in the middle of a large room or external aerodynamics far from the vehicle. It’s robust but notoriously inaccurate for flows with strong pressure gradients or separation.

- k-omega SST: This is our go-to model for most industrial applications. It blends the accuracy of the k-omega model near the wall (great for boundary layers, heat transfer, and aerodynamic drag) with the robustness of the k-epsilon model in the far-field. It costs a bit more computationally but the accuracy gain is almost always worth it.

Mistake #5: Misinterpreting Convergence (When Residuals Lie to You)

So, your residual plot hits that magical 1e-4 line and you pop the champagne, right? Hold on. Residuals only tell you one thing: how well the discretized equations are balanced at that moment. They do not guarantee that your flow field has reached a stable, physically correct state. I’ve seen countless simulations where the residuals looked perfect, but key values like drag or heat flux were still oscillating wildly.

This is a subtle but absolutely critical point. Relying only on residuals is like judging the health of an engine by how quiet it is, without ever checking the oil pressure.

- The CFDSource Method: Monitoring physical quantities (like drag or heat transfer coefficient) for true solution stability.

Instead of just watching residuals, you MUST set up monitors for the physical quantities that actually matter to your design. For an airfoil, create a report for lift and drag coefficients. For a heat sink, monitor the average temperature on the hot surface. Your simulation is only truly converged when these values stop changing and flat-line (or settle into a periodic pattern for unsteady flows). This is non-negotiable for any serious analysis. 📈

Mistake #6: Skipping the Mesh Independence Study (The Most Overlooked Step for Credible Results)

Okay, this is the one that separates the pros from the amateurs. You run your simulation on a 2-million-cell mesh and get a result. Great. But how do you know that a 4-million-cell mesh wouldn’t give you a completely different answer? You don’t. Unless you check.

A mesh independence (or grid convergence) study is the process of running the same simulation on progressively finer meshes until the result you care about stops changing. Yes, it’s more work. Yes, it takes more computational time. But without it, your results are just a pretty picture with an unknown margin of error. It’s a foundational step for validating your simulation against real-world data.

Mistake #7: Using Default Solver Settings for Every Problem (A One-Size-Fits-All Approach That Fails)

Every major CFD package—whether from Ansys, Siemens, or the open-source world—comes with default settings designed to be robust for simple problems. But your problem might not be simple. Sticking with the defaults is often leaving performance and accuracy on the table.

For example, the default SIMPLE pressure-velocity coupling scheme is stable but can be slow to converge for complex flows. Switching to COUPLED can significantly speed things up, provided your mesh quality is good. Similarly, tweaking under-relaxation factors can be the key to getting a stubborn, divergent simulation to finally behave. Knowing which solver to use for which job is key, and it’s a major factor we consider when comparing the best CFD software for different tasks.

Mistake #8: Believing Every Contour Plot (The Art of Post-Processing and Sanity Checks)

A beautiful, colourful contour plot can be incredibly persuasive. It can also be completely wrong. Post-processing is not just about making nice images for your report; it’s about interrogating your data and performing sanity checks. Does the result make physical sense?

Ask yourself simple questions:

- Is the pressure dropping in the direction of flow in a pipe? (It should be!)

- Is the maximum temperature in your electronics cooling simulation higher than the inlet air temperature? (It better be!)

- Are there strange velocity vectors pointing directly into a solid wall? (Red flag!)

You’d be amazed what you can catch with a few minutes of critical thinking. Having the right hardware is also a huge help here, as a powerful machine can make this interactive analysis much smoother. If your current setup is lagging, you might want to check out our guide on building the perfect CFD workstation.

Beyond the Basics: How CFDSource Transforms Beginner Setups into Industry-Grade Simulations

Avoiding these mistakes is a great start. But moving from a “working” simulation to an “industrially reliable” one involves a level of process and rigor. It’s less about finding one magic button and more about a systematic approach to ensure every single step is done correctly and is verifiable.

- (H3) Our Pre-Simulation Checklist: A Glimpse into Our Validation and Verification (V&V) Process.

Before we launch any major simulation for a client, the lead engineer runs through a quick internal checklist. It’s a simple habit that has saved us thousands of hours over the years. It looks something like this:- Geometry Check: All unnecessary features removed? No sliver faces?

- Boundary Conditions Review: Have the BCs been double-checked against the problem statement?

- Mesh Quality Report: Max Skewness < 0.9? Min Orthogonal Quality acceptable?

- Boundary Layer Check: Are there at least 10-15 inflation layers? Is the first cell height calculated correctly for the target y+?

- Monitor Setup: Are all key physical quantities (drag, mass flow, heat transfer) being monitored?

- Final Sanity Check: One last look. Does everything feel right?

Conclusion & Your Next Step: From Common Mistakes to Confident Engineering

CFD can feel like a black box at times, but it isn’t magic. It’s a powerful engineering tool governed by physics and mathematics. Every error, every divergence, has a logical cause. The key is to move beyond just clicking buttons and start thinking critically about each step of the process, from the initial CAD model to the final contour plot.

By understanding and actively avoiding these common CFD mistakes, you’re not just fixing a broken simulation; you’re building the skills and intuition that define a truly competent simulation engineer. Keep practicing, keep questioning your results, and you’ll get there.