Let’s cut right to it. Your CFD simulation is a story, and the boundary conditions are the first and last chapter. Get them wrong, and the entire story falls apart, no matter how brilliant the middle part (your mesh and solver settings) is. It’s a fundamental piece of the puzzle, and if you’re just starting out, it can feel a bit abstract. This guide is here to make it concrete. We’re going to break down how to choose the right boundary conditions in CFD so your results actually mean something in the real world.

Before we dive into the specifics of inlets and walls, it’s crucial to understand the bigger picture of what CFD is all about. Think of your boundaries as the only way your simulated domain can communicate with the outside world. You are telling the solver what’s happening at the edges, so it can figure out everything happening on the inside.

Why Your Boundary Conditions Are the Single Most Critical Decision in Your CFD Simulation

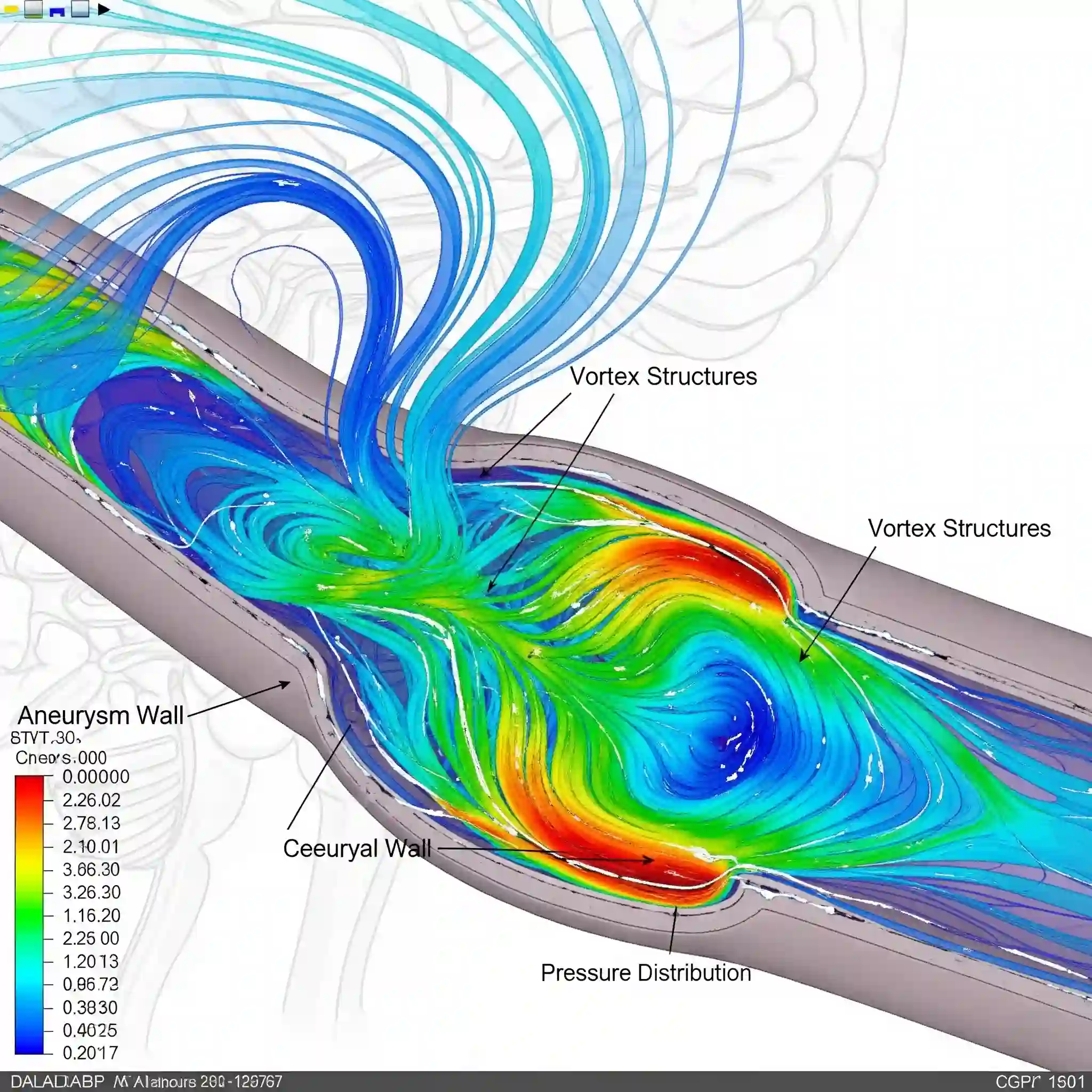

I can’t stress this enough. After 15 years in this field, I’ve seen more projects go off the rails due to a poorly chosen boundary condition than anything else. I remember a heat exchanger project early in my career. We spent two weeks running a simulation, convinced our turbulence model was the issue because the results looked bizarre. The temperatures were completely off. Turns out, the problem was a simple pressure-outlet placed in a region where complex reverse flow was happening. The solver was fighting a condition that was physically impossible. A simple switch to an outflow condition, placed further downstream, saved the project. It was a painful lesson in how a single setting can invalidate weeks of work.

It’s a mistake you make once. Your choice of BC directly dictates the physics of the entire solution. It’s not just a setting; it’s a fundamental assumption about how your system behaves.

The Core Four: Deconstructing Inlet, Outlet, Wall, and Symmetry BCs

Every CFD problem, from airflow over a car to water in a pipe, will use some combination of these four fundamental types. You apply these conditions to the faces of your computational grid, something you can learn more about in our guide to CFD meshing concepts. Let’s quickly define them in plain English:

- Inlet: Where the fluid enters your world. You have to tell the solver how it’s entering (e.g., at what speed, pressure, or mass flow).

- Outlet: Where the fluid leaves. This is often trickier than the inlet because you might not know the exact conditions.

- Wall: An impenetrable boundary. The default assumption is that fluid sticks to it (the “no-slip” condition).

- Symmetry/Periodic: A clever shortcut. A “mirror” that tells the solver the flow on one side is identical to the other, saving massive amounts of computation time. ⏰

1. Mastering Inlet Conditions: Velocity vs. Pressure vs. Mass Flow Rate

Okay, you’re in Ansys Fluent (or your software of choice) and you see three different “inlet” options. Which one do you pick? It completely depends on what you know about the system you’re modeling. One of the biggest hurdles is translating a real-world physical situation into the right mathematical assumption for the solver.

Here’s a quick cheat sheet that I wish I had when I started:

| Boundary Condition | Best For… | Watch Out For… |

| Velocity Inlet | External aerodynamics (e.g., wind speed). When you know the exact inlet velocity profile. | Difficult for internal flows where you usually know pressure or flow rate, not velocity everywhere. |

| Pressure Inlet | When you know the total pressure upstream, like from a tank or plenum. Very robust. | Can be less intuitive than just specifying a speed. Make sure you understand total vs. static pressure. |

| Mass Flow Inlet | Turbomachinery, pipes, or any system where you know exactly how much fluid is being pushed in (e.g., 5 kg/s ). | Can cause convergence issues if your initial guess is far from the final solution. It’s a very “strong” condition. |

For many industrial pipe flow problems, specifying the mass flow rate is the most direct and physically accurate choice. If you’re struggling to model a complex internal system, this decision is critical and often where our expertise as a CFD Consulting Service provides the most immediate value.

2. Decoding Outlet Conditions: The Pressure Outlet vs. Outflow Dilemma

This one trips up everyone. The key difference is the underlying assumption. A Pressure Outlet requires you to specify a static pressure value at the outlet plane. For a pipe venting to the atmosphere, this is perfect—you just set it to 0 gauge pressure. The solver then calculates the velocity and other variables at the outlet based on the upstream flow. It’s the most commonly used and generally stable outlet condition.

The Outflow condition, however, makes a much bigger assumption. It enforces a zero-gradient condition for all flow variables. In simple terms, it assumes the flow profile is no longer changing as it exits the domain (it’s “fully developed”). This can be great if your outlet is very, very far from the interesting parts of your flow, but it can be unstable and cause unphysical results if there are any pressure gradients or complex flow structures near the exit. My rule of thumb: start with Pressure Outlet. Only use Outflow if you have a good reason to.

3. The Wall Boundary Condition: Beyond a Simple No-Slip Condition

You’d think a wall is just a wall, right? Not quite. The default “no-slip” condition is the most common, meaning the fluid velocity right at the wall surface is zero. This is physically accurate for most viscous flows and is responsible for creating the boundary layer.

But you have other options that can be incredibly powerful:

- Moving Wall: Essential for simulating anything with moving parts, like rotating fans, pistons in a cylinder, or conveyor belts. You can specify rotational or translational velocity.

- Specified Shear / Slip Wall: A more advanced option where you define the shear stress on the wall instead of the velocity. Sometimes used to approximate a surface that is very far away.

- Thermal Conditions: This is a big one. Is your wall a fixed temperature? Is there a constant heat flux going into it, like from a computer chip? Or is there convection to the outside air? Your choice here will completely define the heat transfer in your simulation. This is a topic we often see clients struggle with, getting the heat transfer coefficient just write is an art.

4. Symmetry & Periodic BCs: The Secret to Slashing Your Computational Time

If your geometry and the expected flow pattern are symmetrical, using a symmetry boundary condition is a no-brainer. Simulating a quarter of a pipe instead of the whole thing can reduce your cell count (and simulation time) by 75%. That’s a huge win. The solver essentially treats the symmetry plane like a perfect, frictionless mirror.

But be careful. You can only use it if you are absolutely certain the flow itself will be symmetrical. A classic mistake is using a symmetry plane to model flow over a cylinder at a Reynolds number where vortex shedding occurs. The geometry is symmetric, but the resulting flow pattern (the vortices) is not! This will give you completely wrong answers. A simpler model with fewer cells often means you can achieve simulation convergence much faster, but only if the underlying physical assumptions are correct.

A CFDSource Framework: 5 Questions to Ask Before Choosing Any Boundary Condition

Over the years, I’ve developed a mental checklist that I run through for every single simulation, no matter how simple it seems. It helps avoid those “d’oh!” moments later on. Before you click anything in your setup, ask yourself these five questions:

- What physical quantity do I know for sure? Don’t guess. If you have experimental data for the inlet pressure from a gauge, use a pressure inlet. If you know the pump’s flow rate, use a mass flow inlet. Start with the data you trust.

- Is the flow fully developed at this boundary? If the answer is yes, an Outflow condition or a fully developed velocity profile might be appropriate. If not (and it’s usually not), you need to place your boundary far enough away that this assumption becomes true. Messing this up is a classic beginner mistake.

- Is the flow compressible? For high-speed flows (generally Mach > 0.3), pressure and density are linked. This means using Pressure Inlet and Pressure Outlet conditions is almost always the right move, as they correctly handle changes in both pressure and velocity.

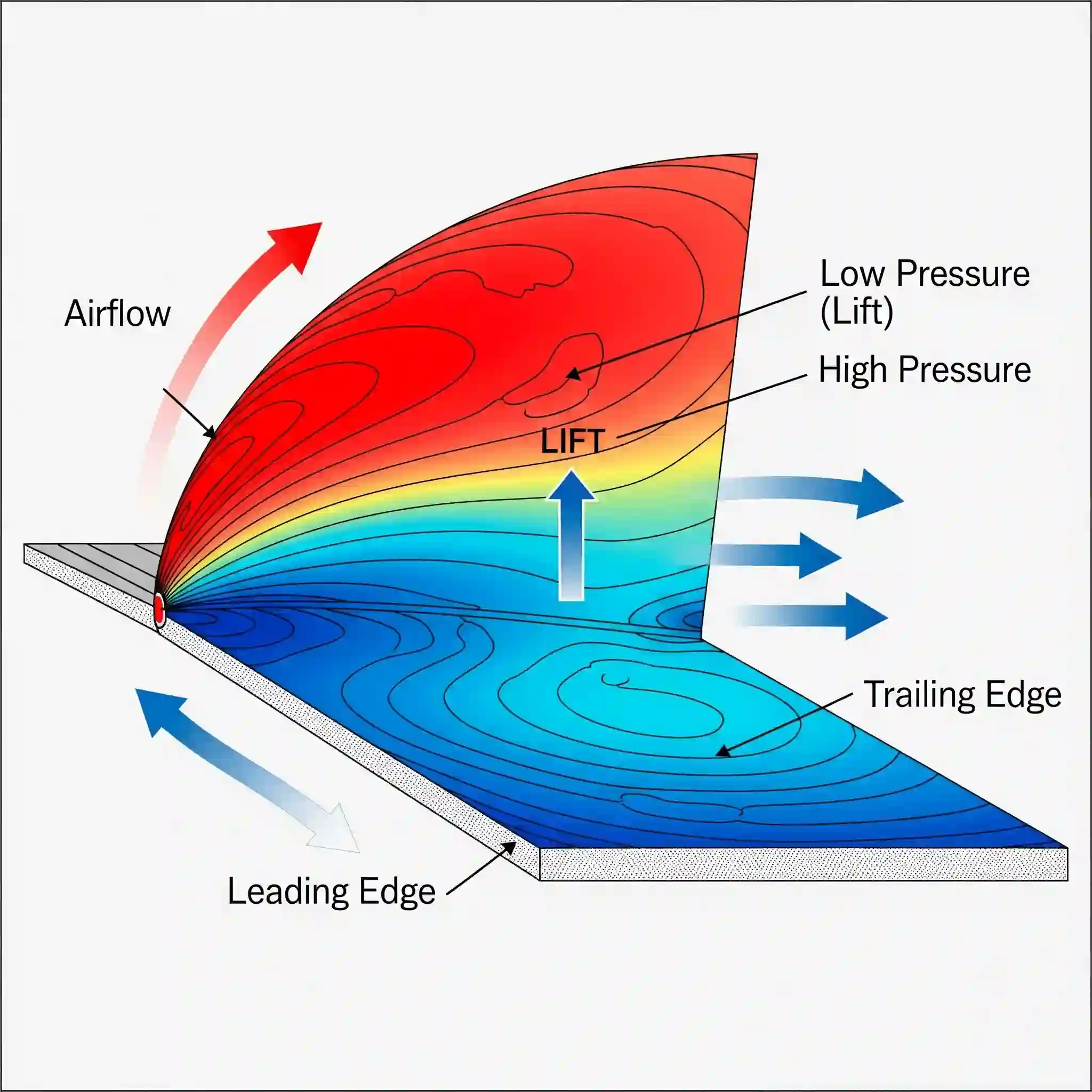

- Is my boundary far enough away? 🤯 This is a big one. If your inlet or outlet is too close to your object of interest (like an airfoil or a valve), the boundary condition itself will artificially influence the flow field and contaminate your results. Always give your flow room to breathe. This often means going back and properly preparing your geometry to include larger inlet/outlet regions.

- Can I use symmetry? Seriously, ask this again. If the answer is yes, you’ve just saved yourself hours or even days of computational time. Just be 100% sure the resulting flow will also be symmetric.

Common Pitfalls and Troubleshooting: Why Your Solution Is Diverging

We learn the most from our mistakes, and in CFD, your solver will happily let you know when you’ve made one by refusing to converge. More often than not, the root cause is a boundary condition that’s fighting the physics.

Error Spotlight: The “Reversed Flow at Pressure Outlet” Warning in Ansys Fluent

If you’ve used Fluent, you’ve seen this warning. It’s infamous. It means that a small vortex or recirculation zone is touching your outlet boundary, causing fluid to try and flow back into your domain. The solver doesn’t like this because a Pressure Outlet is designed for fluid to, well, exit.

The fix is usually simple: extend your outlet domain further downstream. Give that recirculation bubble space to close on itself before it hits the boundary. It’s a classic example of how a small oversight in the geometry setup stage can cause headaches later in the simulation.

The Hidden Dangers of Misplacing Inlet/Outlet Boundaries

Putting boundaries too close to your area of interest is like trying to study a boat’s wake by putting your camera one inch behind the propeller—the camera’s presence affects the very thing you’re trying to measure. In CFD, a nearby boundary can act like an artificial wall, preventing the flow from developing naturally. This can suppress turbulence, alter pressure distributions, and give you a result that looks nice and converged, but is completely wrong.

Industrial Application Deep Dive: A CFDSource Case Study

Let’s talk about a real-world example: a turbocharger compressor. Here, the flow is high-speed, compressible, and turbulent. You can’t just guess your boundary conditions. To accurately predict the compressor map (its performance curve), you must use a Total Pressure Inlet and a Mass Flow Rate Outlet. Why? Because total pressure represents the energy of the flow upstream, and the mass flow rate is what you’re directly controlling to find different operating points.

Using a simple Velocity Inlet here would be a critical error. It doesn’t account for density changes and won’t capture the physics of the compressor correctly. This setup also demands a robust turbulence model, which is a whole other topic you can explore in our guide on turbulence models like k-omega SST.

Validating Your Choices: How to Ensure Your Boundary Conditions Are Correct

How do you know you got it right? The first sanity check is a mass balance. Does the mass flow rate entering your domain equal the mass flow rate leaving it? If not, you have a major problem. Most solvers report this balance in the console.

Second, look at your results. Visualize the flow at the boundaries themselves. Are the velocity profiles realistic? Is the pressure distribution smooth? If you see strange, sharp gradients right at an outlet, it’s a red flag that the boundary might be too close or the wrong type. Mastering the art of visualizing your CFD results is key to building confidence in your setup.

Key Takeaways: A Final Checklist for Robust CFD Setups

- Start with What You Know: Base your BCs on known physical quantities.

- Give Flow Room: Place boundaries far from your region of interest.

- Pressure BCs for Compressible Flow: Use them for high-speed simulations.

- Use Symmetry Wisely: It’s your best friend for saving time, but only if the flow is truly symmetric.

- Check Your Balances: Always confirm that mass, momentum, and energy are conserved.

Facing a Complex Boundary Condition Challenge?

Look, some problems are just plain hard. Multiphase flows, fluid-structure interaction (FSI), or simulations with complex chemical reactions often have boundary conditions that go beyond the scope of any standard guide. The interaction between phases or the deformation of a wall introduces a whole new level of complexity.

These are the kinds of unique industrial challenges where a standard guide might not be enough. This is where understanding the fundamental physics and having years of hands-on experience matters most. There’s no substitute for expertise when it comes to the nuances of how to choose appropriate boundary conditions in CFD simulations.