So, you’re diving into the world of CFD. Before you get lost in colorful contour plots and complex physics, let’s talk about the single most important—and often overlooked—foundation of any reliable simulation: the mesh. Think of this not just as a technical step, but as the very language your computer uses to understand fluid flow. For a broader overview of how this fits into the big picture, our ultimate guide to what CFD is is a great starting point.

This isn’t just another textbook definition page. We’re going to break down what actually matters in practice, based on what works and what fails in real-world engineering projects.

Why Your CFD Simulation is Only as Good as Your Mesh

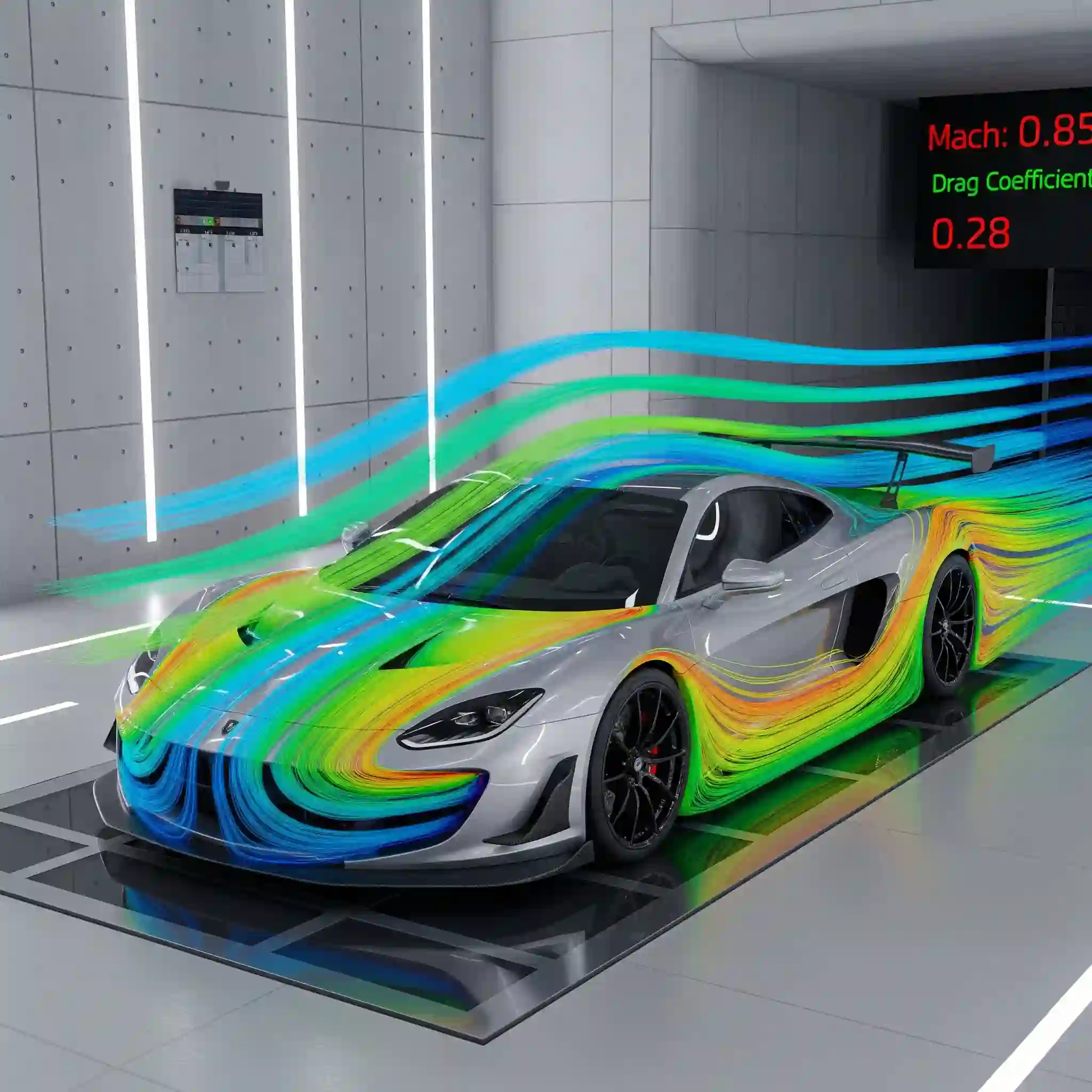

Ever heard the term “Garbage In, Garbage Out”? In CFD, your mesh is the “In”. A poor-quality mesh can introduce errors that cascade through your entire calculation, leading to results that look plausible but are completely wrong. It can mean the difference between correctly predicting the drag on a vehicle and being off by 30%, or failing to capture a critical hot spot in an electronics cooling simulation. The solver is just a number-cruncher; it blindly trusts the grid you give it.

What is a Mesh? Translating Complex Geometry into a Solvable Language

At its core, a mesh, or grid, is the process of breaking down your continuous geometric space (like a pipe, an airplane wing, or a heat sink) into thousands or millions of smaller, simpler shapes called cells or elements. It’s basically turning a complex CAD model into a solvable puzzle for the computer. This process is called discretization.

Before you can even think about meshing, your geometry has to be perfect. Any tiny gaps or overlapping surfaces will cause major headaches. We see it all the time. That’s why a solid understanding from a practical guide to geometry cleanup is non-negotiable. Its not the glamorous part of CFD, but skipping it is a recipe for disaster.

Structured vs. Unstructured Meshes: A Practical Guide for Engineers

You’ll hear these two terms a lot. They aren’t complicated:

- Structured Meshes (Hexahedral): Think of a perfect, orderly grid of cubes or rectangles (in 3D, we call them hexahedra). They are computationally efficient and highly accurate. The problem? They only work for very simple geometries. A perfect pipe, maybe. A car engine? Forget it.

- Unstructured Meshes (Tetrahedral): These are made of triangular-faced pyramids (tetrahedra). They are incredibly flexible and can be automatically generated for even the most complex shapes you can imagine. The trade-off is that they require more memory and can be less accurate for the same cell count.

Hybrid Meshing: The Go-To Strategy for Complex Industrial Models at CFDSource

So which one do you choose? In reality, almost never just one. The professional approach is hybrid meshing. We use the best of both worlds. We’ll use thin, structured, brick-like cells (prisms or hexas) right next to the walls to accurately capture the boundary layer—that super thin region of fluid where all the important stuff like friction and heat transfer happens. Then, we fill the rest of the domain with flexible unstructured tetra cells.

I remember a turbocharger turbine housing project from years ago. The geometry was a nightmare. Our initial all-tetrahedral mesh just wouldn’t converge, no matter what we tried. After two days of frustration, we went back and painstakingly built a hybrid mesh with inflation layers around the blades. The simulation converged beautifully, and the results for turbine efficiency matched the client’s experimental data within 2%. That was one of those moments in my 15 years in this field that hammered home: the mesh isn’t a step before the simulation; it is the simulation. It’s where many of our CFD consulting services add the most value. ⚙️

The Core Pillars of Mesh Quality: Metrics That Define Success or Failure

Okay, so we have a mesh. How do we know if it’s any good? We don’t guess. We use metrics—specific numbers that tell us the health of our cells. Your CFD software will report these, and learning to read them is critical. Let’s look at the big three that cause 90% of the problems.

Skewness & Orthogonality: How Cell Shape Dictates Your Simulation’s Stability

These two are all about cell shape. Skewness is a measure of how distorted a cell is from its ideal shape (e.g., a perfect equilateral triangle or a cube). A high skewness value is bad news. It means your cell is squashed or stretched, which makes it very difficult for the solver to accurately calculate gradients across it. As a rule of thumb we’ve developed at CFDSource, we always aim for a maximum skewness below 0.85, and ideally, keep the average well below 0.3. Anything above 0.95 is asking for trouble.

Orthogonality is another key metric, especially for finite-volume solvers. It measures how close the angles between cell faces and the lines connecting cell centers are to 90 degrees. Poor orthogonality can mess up the flux calculations between cells, leading to slow convergence or inaccurate results. This is particularly important when understanding different turbulence models, as they are highly sensitive to the quality of gradients near the wall. High quality mesh is just one of those things that makes everything else work better.

Aspect Ratio: When and Why Elongated Cells Become a Problem

Aspect Ratio is simply the ratio of the longest side of a cell to its shortest side. For a perfect cube, the aspect ratio is 1. A lot of beginners are taught that a high aspect ratio is always bad. That’s only half true.

In the middle of your fluid domain, where flow is happening in all directions (isotropic), you want cells that are as close to a perfect cube/tetrahedron as possible. A high aspect ratio here can hurt accuracy. But inside the boundary layer, right next to a wall, the flow gradients are huge in the direction perpendicular to the wall and small in the direction parallel to it. Here, we want high aspect ratio cells—thin, flat, pancake-like elements. Aspect ratios of 100:1 are not only acceptable here; they’re essential for efficiency and accuracy.

Demystifying Y+: The Critical Bridge Between Your Mesh and Turbulence Physics

If there’s one metric that separates the beginners from the pros, it’s Y+ (pronounced Y-plus). Y+ is a non-dimensional number that represents the distance from the wall to the center of the first mesh cell. Why does this matter so much? Because your turbulence model’s accuracy depends entirely on it.

Think of it this way: some turbulence models (like the standard k-epsilon) use “wall functions” to bridge the gap between the wall and the fully turbulent region. They don’t resolve the boundary layer directly, so they need the first cell to be outside the viscous sublayer (typically a Y+ between 30 and 300). Other models (like k-omega SST) are designed to resolve the physics all the way to the wall. For them, you absolutely must have your first cell inside the viscous sublayer (Y+ < 5, and ideally Y+ ≈ 1). Using the wrong Y+ for your chosen model is one of the fastest ways to get garbage results.

Practical Application: A CFDSource Workflow for High-Quality Meshing

So, how does this all come together in a real project? Here’s a simplified look at how we approach it.

- Geometry First, Always: As we said, the process starts with a perfectly clean CAD model. No shortcuts.

- Boundary Layer Inflation: We identify all the critical walls and create inflation layers. We don’t guess the thickness; we use calculators to estimate the required first-cell height to hit our target Y+ value. This is a crucial planning step.

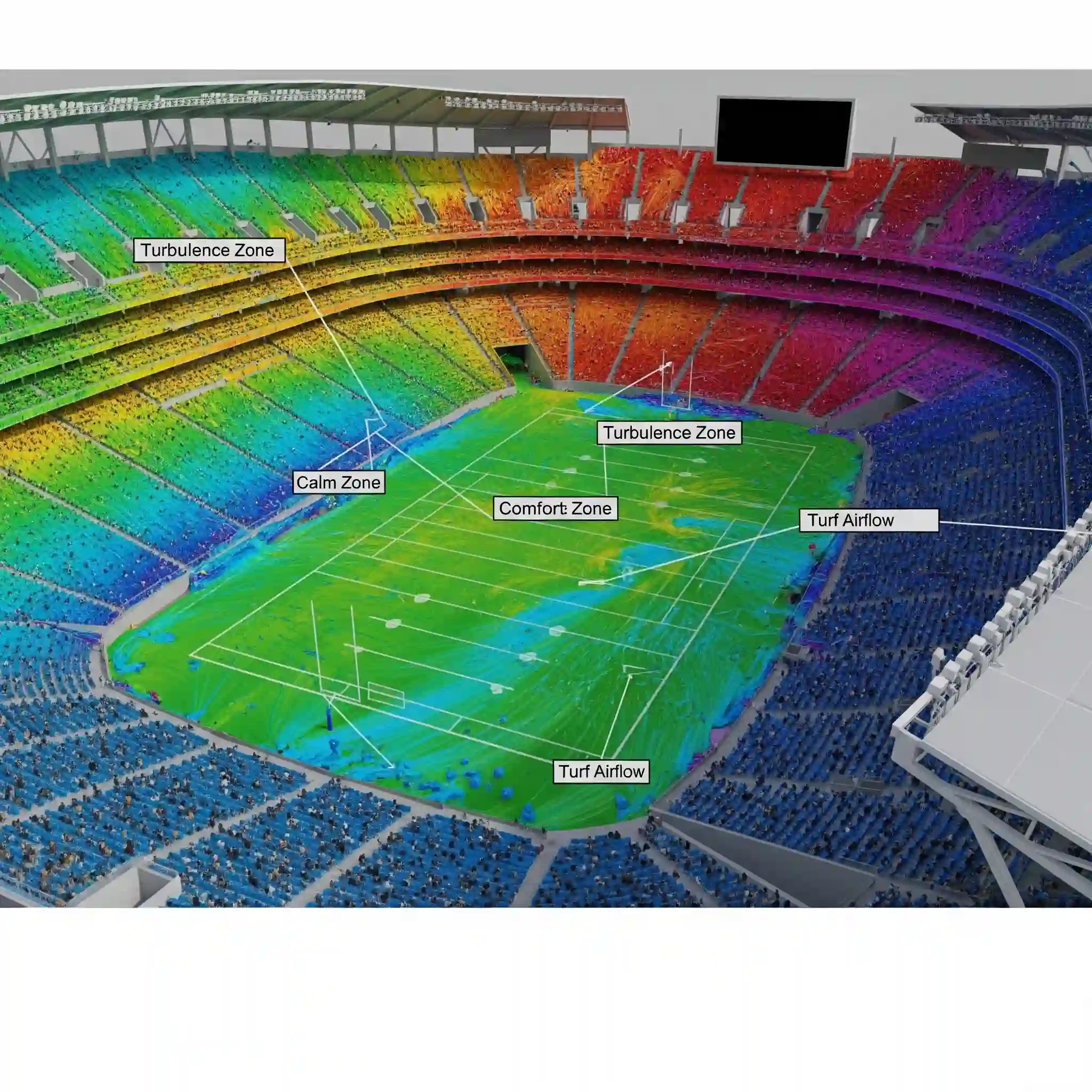

- Volume Fill & Refinement: We then fill the remaining volume, usually with tetrahedral cells, and add local refinement. This means using smaller cells in areas where we expect complex flow physics (like wakes, jets, or separation zones) and larger cells where the flow is simple to save computational cost.

- The Mesh Independence Study: This is non-negotiable for any serious analysis. We run the simulation on our baseline mesh, then refine it (e.g., reduce cell size by 20%) and run it again. We keep doing this until a key result, like drag force or pressure drop, stops changing significantly. Now, and only now, can we trust our results. It’s the only way to be sure that what you’re seeing isn’t just an artifact of your grid.

Common Meshing Pitfalls and How to Troubleshoot Them

Error Spotlight: Why You’re Seeing “Floating Point Exception” and How to Fix It

That dreaded error. A “floating point exception” during a run is often a sign of a critical mesh issue. It frequently means you have cells with negative volume, which can happen with highly skewed or warped cells, especially in complex geometries. Your first step should always be to go back to the mesher, check your quality metrics, and find and fix those few bad cells. Its almost never a solver problem.

The Hidden Cost of “Auto-Meshing” on Complex Industrial Projects

The “mesh” button is tempting. It promises a finished mesh in one click. 🧙♂️ But for any serious industrial application, automatic meshing algorithms often produce a mesh that is “good enough” to run, but not “good enough” for accuracy. You might end up with poor boundary layer resolution or insufficient refinement in key areas. The hidden cost is hours of wasted solver time on a simulation that either won’t converge properly or gives you misleading results. A few extra hours of manual meshing up front can save days of headaches later.

Your Pre-Simulation Meshing Checklist: 7 Steps to a Convergent Solution

Before you hit “run,” go through this quick list:

- Check Max Skewness: Is it below 0.9? (Ideally < 0.85)

- Check Orthogonality: Is the minimum quality acceptable for your solver?

- Visual Inspection: Zoom in on critical areas. Do you see any highly distorted cells?

- Boundary Layer Check: Are there at least 10-15 layers in your boundary layer mesh?

- Y+ Estimate: Did you calculate your first layer thickness correctly for your turbulence model?

- Interfaces: Are the connections between different mesh zones conformal and without gaps?

- Boundary Naming: Have you correctly named all your boundaries? This is critical for choosing the right boundary conditions in the next step.

How CFDSource Guarantees Simulation Fidelity with Expert Meshing Services

How do we ensure every project gets a high-fidelity mesh? It’s about process. Every mesh is peer-reviewed by another engineer before it goes to the solver. We use scripting to automate repetitive tasks, which reduces human error and ensures consistency. Most importantly, our validation process means we don’t just trust the pretty pictures; we benchmark our simulation models against experimental data or established theory whenever possible. This is the level of rigor our Fluid Dynamics Consultants bring to every analysis.

Conclusion: Build Your Next Project on a Foundation of Confidence

At the end of the day, meshing is a craft that blends science and art. It requires a deep understanding of fluid dynamics, numerical methods, and the specific goals of your project. While the solver gets all the glory, the mesh is the unsung hero that does the hard work. Getting it right is the first and most critical step toward achieving convergence and trusting your results.

Once you have a solid mesh and a converged solution, the next exciting step is to dive into the results, which you can learn about in our beginner’s guide to post-processing. Mastering these fundamentals provides a complete introduction to CFD meshing and sets you up for success in any simulation you tackle.