Why Your CFD Software Choice in 2025 is More Critical Than Ever

Picking a CFD tool isn’t like choosing a new coffee machine. Get it wrong, and you’re not just out a few bucks; you’re potentially weeks behind schedule with results that look impressive but are fundamentally flawed. I’ve seen it happen. The wrong choice can burn through your project budget and, worse, give you beautiful-looking plots that are completely misleading. Before we even compare tools, if you’re just getting started in this field, it’s worth understanding the fundamentals of what computational fluid dynamics actually is. This guide isn’t about just listing features; it’s about giving you the mental framework you need to find the best CFD software for your specific job in 2025.

The Core Criteria for Choosing a CFD Tool: A Framework for Engineers

Let’s cut through the marketing noise. Every software website will promise you the world. After well over a decade wrestling with these tools on real industrial problems, I’ve learned to evaluate them based on a few core principles. This isn’t just a checklist; it’s a way of thinking that protects you from choosing a tool that’s a poor fit for your work. We’ll look at accuracy, ease of use, the real cost, and how deep the physics solvers actually go.

Accuracy, Validation, and Reliability: What’s at Stake?

This is everything. I remember a heat exchanger project early in my career where our simulation was a solid 20% off from the prototype’s performance. The mesh looked good, the residuals converged beautifully, but the heat transfer model we used was too simplified for the operating conditions. It was a painful lesson in validation. A flashy user interface means nothing if the solver is a black box you can’t trust.

This isn’t just about getting the right answer; its about knowing how right your answer is. Can you trust it enough to cancel a multi-thousand dollar physical test? That’s the real question. It’s why we obsess over how to properly validate CFD results against real-world data. Without that step, you’re just making expensive art.

Ease of Use vs. Power & Flexibility: Finding Your Balance

There’s a constant tug-of-war here. On one end, you have tools with slick, intuitive interfaces that can get you from CAD to a basic result in an afternoon. On the other end, you have command-line driven tools that offer near-infinite control but demand you have a deep understanding of the underlying numerical methods.

Think of it like a point-and-shoot camera versus a full DSLR. One is fast and easy, the other gives you the power to create a masterpiece if you know what you’re doing. A steep learning curve often leads to some of the most common CFD simulation mistakes we see, simply because the user doesn’t grasp the settings they’re changing. Your choice depends on your team’s skil level and how much customization you truly need.

Total Cost of Ownership: Beyond the Initial License Fee

This is where many managers get it wrong. They see “Free” (like OpenFOAM) and think they’ve hit the jackpot. 💡 But the license fee is just the tip of the iceberg. A “free” tool that takes your PhD student six months to learn isnt’ really free, is it? Your engineer’s time is your most expensive asset.

You also have to factor in the hardware. Running a serious simulation requires significant computing power. Building a powerful CFD workstation isn’t cheap, and for large cases, you might even need access to a high-performance computing (HPC) cluster. Cloud solutions like SimScale roll this cost into their subscription, which can be a game-changer for smaller companies.

Multiphysics Capabilities & Solver Depth

Sometimes, fluid flow is only part of the story. What if the fluid’s heat is causing a solid part to expand and deform? That’s a Fluid-Structure Interaction (FSI) problem. Or what if an electrical current is generating heat that then drives fluid motion? That’s a coupled thermal-electric-fluid problem. This is the realm of multiphysics.

Some software packages handle these tightly coupled physics beautifully, while others treat them as an afterthought. It’s crucial to know if you’ll need this capability down the line. For truly complex coupled problems, you often need a specialized fluid dynamics consultant who understands both the physics and the software’s limitations. Don’t just check a box that says “multiphysics”; ask how it couples the physics.

The Industry Titans: A Deep Dive into Ansys (Fluent & CFX) and COMSOL Multiphysics

Alright, let’s get into the heavyweights. If you’ve spent any time in engineering simulation, you’ve heard of Ansys and COMSOL. These are the established, commercial powerhouses with decades of development and validation behind them. They’re expensive, powerful, and for many industries, the undisputed standard.

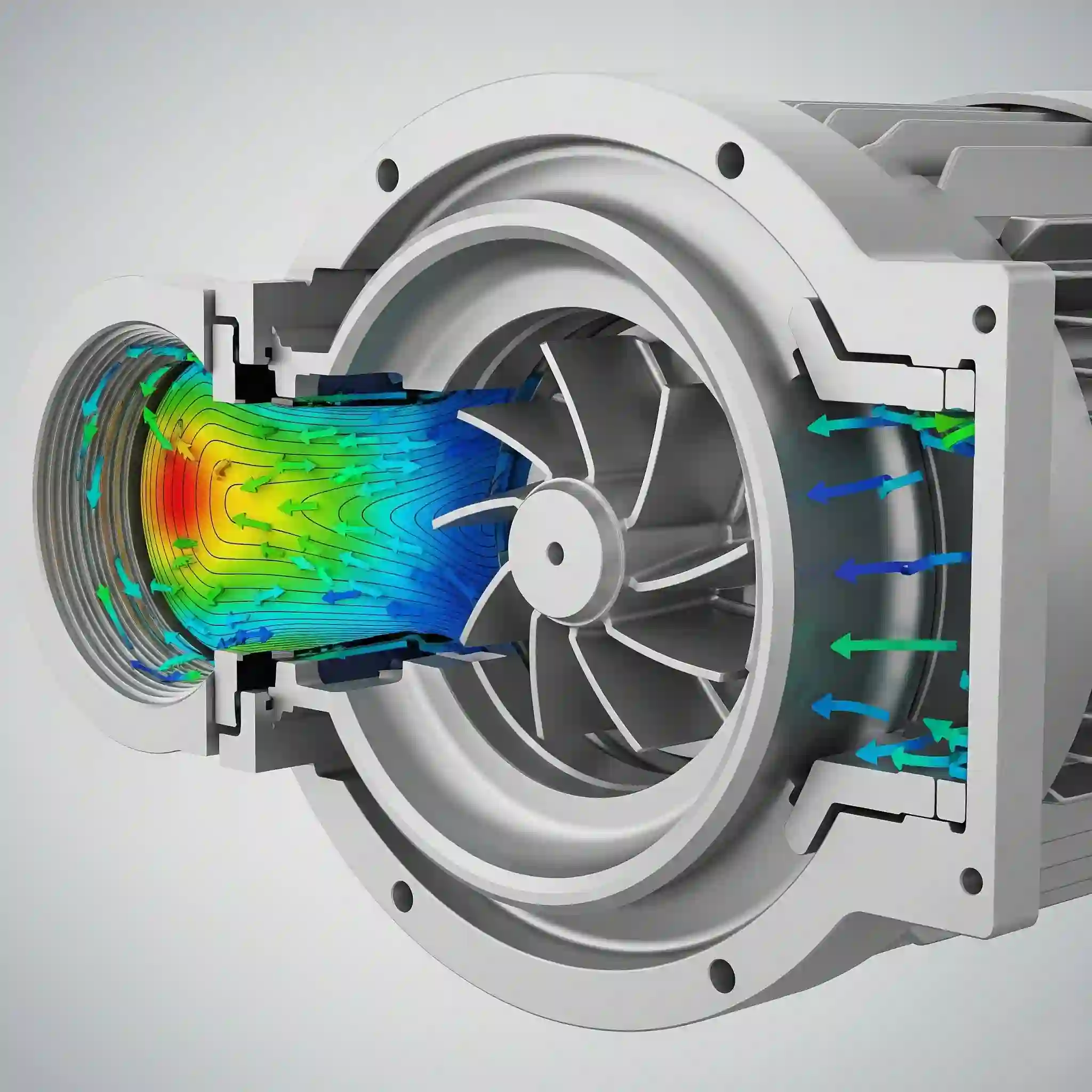

Ansys: The Go-To for Robust, High-Fidelity Industrial Simulation

When you talk about CFD in industries like aerospace, automotive, or turbomachinery, you’re usually talking about Ansys Fluent or Ansys CFX. It’s the tool you use when you can’t afford to be wrong. The solvers are mature, extensively validated, and trusted by nearly every major engineering firm on the planet. The ecosystem is massive, with powerful meshing tools and pre/post-processing capabilities. The downside? The learning curve can be steep, and the price tag is significant. But for high-stakes, industrial-grade simulation, it’s often the default choice for a reason.

COMSOL: The Master of Tightly-Coupled Multiphysics Problems

If Ansys is the industrial workhorse for fluids, COMSOL is the brilliant scientist in the lab. Its entire philosophy is built around solving multiple physics simultaneously. Where other codes might need complex co-simulation setups to handle things like fluid flow inducing stress on a solid part, COMSOL solves them in a single, unified environment. I once worked on a microfluidic device where Joule heating from an electric field was driving the flow. In any other software, it would have been a nightmare to couple. In COMSOL, it was a natural workflow.

The core of this power comes from its foundation. While most traditional CFD codes use the Finite Volume Method, COMSOL is primarily based on the Finite Element Method. This subtle difference has huge implications, and understanding the distinction between FVM and FEM for fluid dynamics is key to appreciating why COMSOL excels at certain problems. It’s not always the fastest for pure, high-Reynolds number aerodynamics, but for anything involving tightly coupled physics, it’s in a league of its own.

The Disruptors: A Look at OpenFOAM and SimScale

Now for the interesting ones. OpenFOAM and SimScale represent a fundamental shift away from the traditional model of buying expensive licenses and running them on in-house hardware. They are challenging the status quo, but they come with their own distinct trade-offs.

OpenFOAM: Ultimate Freedom and Customization for the Expert User

OpenFOAM is pure, unadulterated power. It’s a C++ library of solvers, not a polished software package. There’s no official GUI, and the learning curve is less of a curve and more of a vertical cliff. 🧗♂️ So why on earth would anyone use it? Because it’s completely free and you have access to the source code.

This means if you need a specific boundary condition or a custom turbulence model that doesn’t exist in commercial codes, you can write it yourself. For academic research or highly specialized industrial R&D, this is invaluable. It demands a lot from the user, but the payoff is total control. Be warned: “free” in license cost often translates to “expensive” in terms of engineer’s time and training.

SimScale: CFD on the Cloud – Accessibility and Collaboration Redefined

SimScale’s proposition is simple and powerful: what if you didn’t need a powerful computer at all? It’s a 100% cloud-based platform accessed through your web browser. You upload your CAD, set up the simulation, and their massive server farms do the heavy lifting. This is a game-changer for startups, consultants, and teams that need agility.

The collaboration aspect is fantastic. Instead of emailing massive result files, you just share a project link. This makes it incredibly easy to work with an external partner, like a CFD consulting service, for project review or troubleshooting. The platform is getting more powerful every year, and while it might not have the sheer depth of Ansys for every niche application, its ease of use and pay-as-you-go model makes CFD accessible to a much wider audience.

Head-to-Head Decision Matrix: Which Software Wins for Your Specific Application?

Let’s distill all this into a practical guide. There is no single “winner.” The best choice depends entirely on your context. This table is my honest breakdown based on years of using these tools for different jobs.

| Criterion | Ansys (Fluent/CFX) | COMSOL Multiphysics | OpenFOAM | SimScale |

| Best For… | High-fidelity, validated industrial simulations (aerospace, turbomachinery) | Tightly-coupled multiphysics (FSI, electromagnetics, acoustics) | Academic research, custom solver development, budget-constrained experts | Startups, quick design iterations, teams without dedicated hardware |

| Key Strength | Robustness, validation, and a massive ecosystem. | Unmatched multiphysics solver integration. | 100% customizable and free (as in freedom). | Accessibility, collaboration, and zero hardware overhead. |

| Learning Curve | High. Very powerful but complex. | Moderate to High, especially for deep physics. | Extremely High. Requires Linux and coding skills. | Low to Moderate. Very intuitive interface. |

| Cost Model | High upfront license cost + annual maintenance. | High upfront license cost + annual maintenance. | Free license. High cost in personnel time/training. | Subscription-based (SaaS). Pay for core-hours. |

| Hardware Needs | Powerful dedicated workstation or HPC cluster required. | Powerful workstation required. | Can run on a laptop, but needs a powerful workstation for real work. | A web browser. That’s it. |

From Our Experience: Real-World Scenarios Where One Tool Outshined the Others

Theory is one thing, but project deadlines are another. Here are a few quick examples from our work.

- Scenario for Ansys: We had to analyze the aerodynamic performance of a new wing profile for a client with incredibly strict certification requirements. The results needed to be defensible and validated against known experimental data. Ansys Fluent was the only real choice for that level of rigor and industry acceptance.

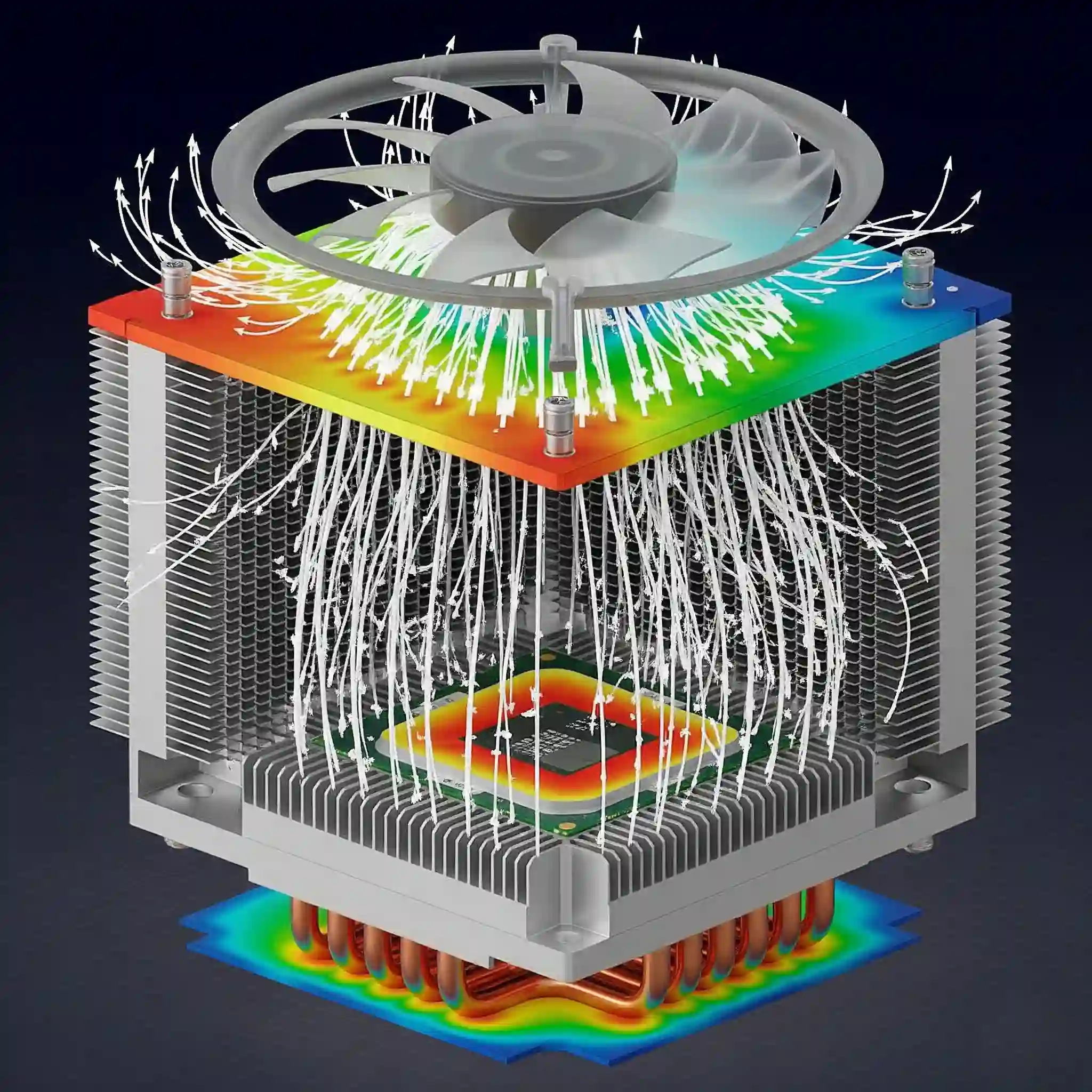

- Scenario for SimScale: A startup developing a new electronic device needed to quickly iterate on their heatsink design. They didn’t have a big budget or a simulation expert on staff. Using SimScale, their mechanical engineer was able to test ten different designs in a week, all without buying a single piece of new hardware.

- Scenario for OpenFOAM: A university research group needed to simulate a novel chemical reactor with a non-standard reaction model. No commercial code had the specific physics they needed. We helped them implement a custom solver in OpenFOAM, giving them the capability to publish their groundbreaking research.

The Final Verdict: It’s Not the “Best” Software, It’s the Right Partner

So, after all that, what is the best CFD software? The answer is boring but true: it depends. It depends on your budget, your timeline, your team’s expertise, and the physics of your problem. Choosing the software is just the first step. The real challenge—and where the real value lies—is in correctly applying it. It’s about building a good mesh, choosing the right physical models, and knowing how to interpret the results.

Don’t Let Software Choice Be Your Bottleneck. Let CFDSource Experts Guide You.

The tool is only as good as the person using it. An expert with a basic tool will get more reliable results than a novice with the most expensive package on the market. Once you have an idea of the software you need, the next step is implementation. Ensuring your simulations are set up correctly, validated, and actually solve your engineering problem is the most critical part of the process. That’s where true experience makes all the difference.