The Critical Choice: Why FVM vs. FEM Isn’t Just Academic—It’s Your Project’s Foundation

So, you’re staring at a fluid dynamics problem and the age-old question pops up: FVM or FEM? It feels like a choice between two different programming languages. Pick the wrong one, and you could be fighting your simulation for weeks, only to get results that don’t make physical sense. This isn’t just a textbook debate; it’s a decision that directly impacts your project’s timeline, budget, and the reliability of your data.

Before we dive deep into the methods, if you’re looking for a broader overview of the entire field, our guide on what is computational fluid dynamics is the perfect starting point. But here, we’re getting into the nuts and bolts of the solvers themselves. My goal is to give you the practical, on-the-ground perspective you need to make the right call, based on years of seeing what works and what doesn’t.

Back to Basics: What is the Finite Volume Method (FVM) at its Core?

Think of FVM as a meticulous accountant for physics. It breaks your entire domain (like the air around a car) into thousands of tiny boxes, or “control volumes.” For each and every one of these boxes, it strictly enforces the conservation laws—mass in must equal mass out, energy in must equal energy out, and so on.

It doesn’t care so much about what’s happening at the exact points (nodes); it’s obsessed with the fluxes—the stuff crossing the boundaries of each volume. This fundamental approach is what makes it so incredibly robust for fluid flow problems.

The Power of Conservation: Why FVM is the Natural Choice for Flow Physics

Because FVM is built from the ground up on the principle of conservation, it’s inherently good at handling things that are central to fluid dynamics: shockwaves, sharp gradients in pressure, and boundary layers. The method ensures that mass, momentum, and energy are conserved perfectly, both locally in each cell and globally across the whole domain. This is non-negotiable for aerospace or turbomachinery simulations.

Getting this choice right from the start is critical. It’s one of the easiest ways of avoiding some common CFD simulation mistakes that can derail a project later on. If your physics is dominated by convection and transport phenomena, FVM is almost always your safest and most efficient bet.

The Industry Standard: FVM in Software like Ansys Fluent & STAR-CCM+

There’s a reason why the titans of the CFD industry—software like Ansys Fluent, STAR-CCM+, and the open-source hero OpenFOAM—are predominantly FVM-based. They are designed to be general-purpose flow solvers that can handle a massive range of industrial problems with high stability and speed. ⚙️

Deconstructing the Alternative: How Does the Finite Element Method (FEM) Work for Fluids?

FEM comes at the problem from a different angle. It was born in the world of structural analysis. Instead of balancing fluxes across faces, FEM tries to minimize the error of a governing equation across the entire domain. It does this by approximating the solution within each “element” (think of them as little shapes, often triangles or tetrahedra) using simpler, piecewise functions.

It’s a bit like trying to draw a complex curve by connecting a series of short straight lines. With enough short lines, you get a very accurate representation. This approach gives FEM incredible flexibility, especially for problems where the physics isn’t just about fluid flow.

From Structures to Fluids: The Versatility of Piecewise Functions

This mathematical flexibility is FEM’s superpower. It’s fantastic at handling weirdly shaped, complex geometries because the elements don’t have to be perfect boxes. It’s also exceptionally good when you need very high-order accuracy for specific problems, like some types of acoustic simulations.

But for standard fluid dynamics, it can sometimes be overkill and computationally heavier. The conservation of mass and momentum isn’t as naturally “built-in” as it is with FVM, and it often requires special mathematical treatment to ensure physical results, which is something many users dont realize.

FEM’s Domain: Where COMSOL Multiphysics & Ansys Mechanical Shine

You’ll see FEM at the heart of software like COMSOL Multiphysics for a reason. Its strength is coupling different physics together—like fluid flow with structural deformation (FSI), electromagnetics, or chemical reactions. Ansys Mechanical also uses FEM for its fluid elements when doing FSI. If your problem is more than just fluids, FEM is often the superior choice.

The Head-to-Head Comparison: FVM vs. FEM on Key Performance Metrics

Alright, enough theory. Let’s put them side-by-side. The decision of Finite Volume Method (FVM) vs. Finite Element Method (FEM) often comes down to a trade-off between these key engineering metrics. Seeing it all in a table makes the choice much clearer. 🤔

| Feature | Finite Volume Method (FVM) | Finite Element Method (FEM) | The CFDSource Takeaway |

| Physical Principle | Integral Conservation over control volumes. Excellent at ensuring mass/momentum is conserved. | Differential Equation Minimization using weighted residuals. More mathematical and abstract. | For pure fluid dynamics, FVM’s physical approach is more intuitive and robust. |

| Accuracy & Validation | Very strong for convection-dominated flows (high Reynolds numbers). Results are easier to interpret. | Can achieve very high accuracy, especially for diffusion-dominated problems or with high-order elements. | Accuracy is meaningless without proof. We always stress the need for a proper validation of CFD results against real-world data, regardless of the method used. |

| Mesh Flexibility | Handles structured and unstructured meshes well, including modern polyhedral meshes. It is very robust. | Historically superior for highly complex, irregular geometries. Excellent with unstructured tetrahedral meshes. | This gap is closing, but FEM still has a slight edge for extremely bizarre geometries or where mesh deformation is severe. |

| Computational Cost | Generally faster and requires less memory for large, pure fluid dynamics problems. | Can be more computationally expensive, especially for 3D fluid problems, due to larger matrix stencils. | For a large-scale industrial project, this difference can mean days of simulation time. Optimizing this is a key part of our CFD consulting services. |

| Typical Software | Ansys Fluent, STAR-CCM+, OpenFOAM, CFX | COMSOL Multiphysics, Ansys Mechanical (Fluids), Abaqus/CFD | Your choice of software often dictates the method, so choose your tool wisely based on teh problem. |

The CFDSource Playbook: When to Choose FVM (Based on 50+ Industrial Projects)

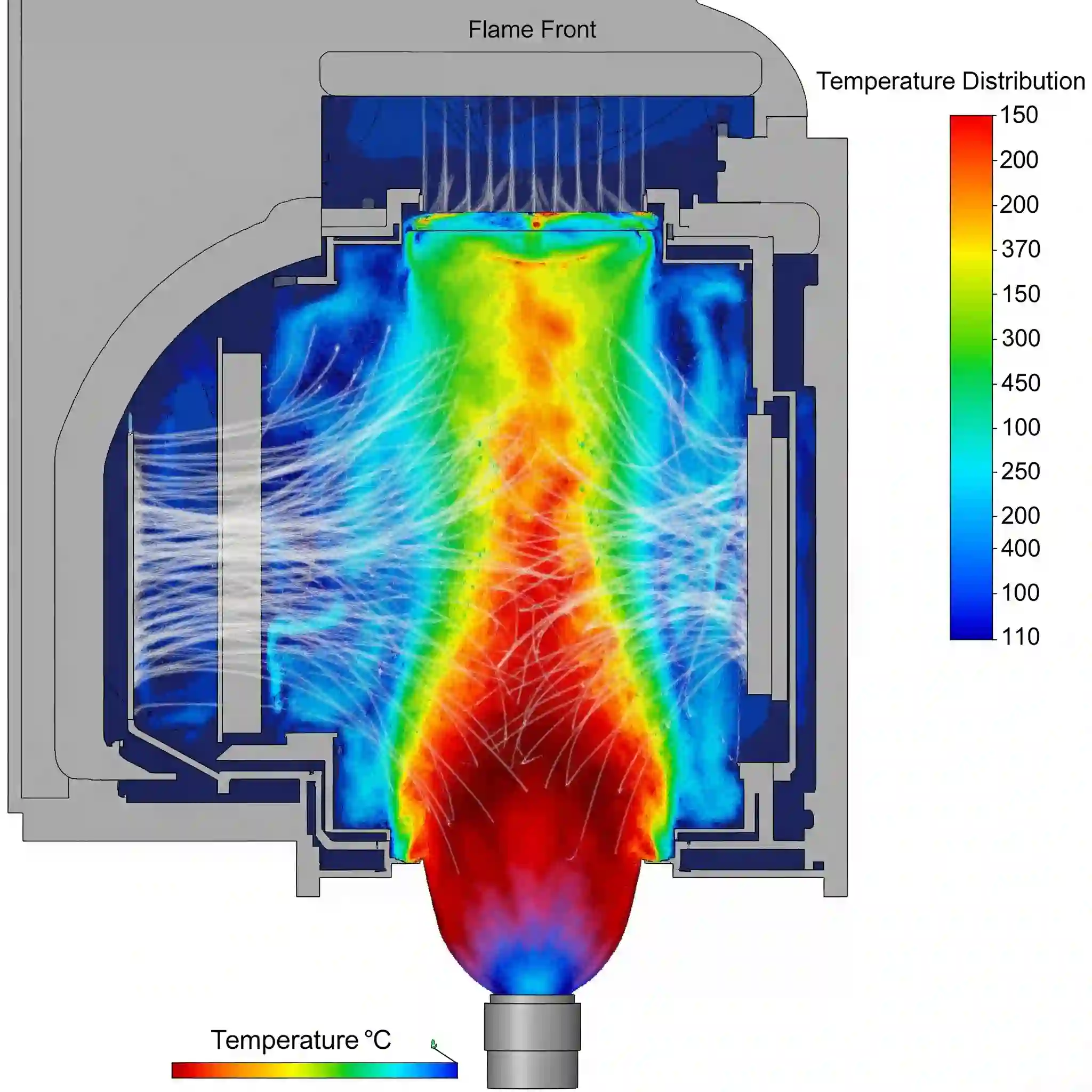

So, when do we, without hesitation, reach for an FVM-based solver? It’s our default for the vast majority of “pure” fluid dynamics and heat transfer problems. Think external aerodynamics over a vehicle, predicting the pressure drop in a complex piping network, or simulating the airflow and temperature distribution in a data center (HVAC).

Let me give you a real example. We once had a project simulating stall conditions in a high-speed axial compressor. The flow field was a mess of shockwaves and severe boundary layer separation. An FVM solver handled it beautifully, capturing the shock locations accurately because its cell-by-cell conservation approach is just built for that kind of punishment. Trying to do that with a standard FEM code would have been a stability nightmare.

The CFDSource Playbook: When FEM is Your Unbeatable Ally

But then, there are times when FEM is an absolute lifesaver. This is its territory:

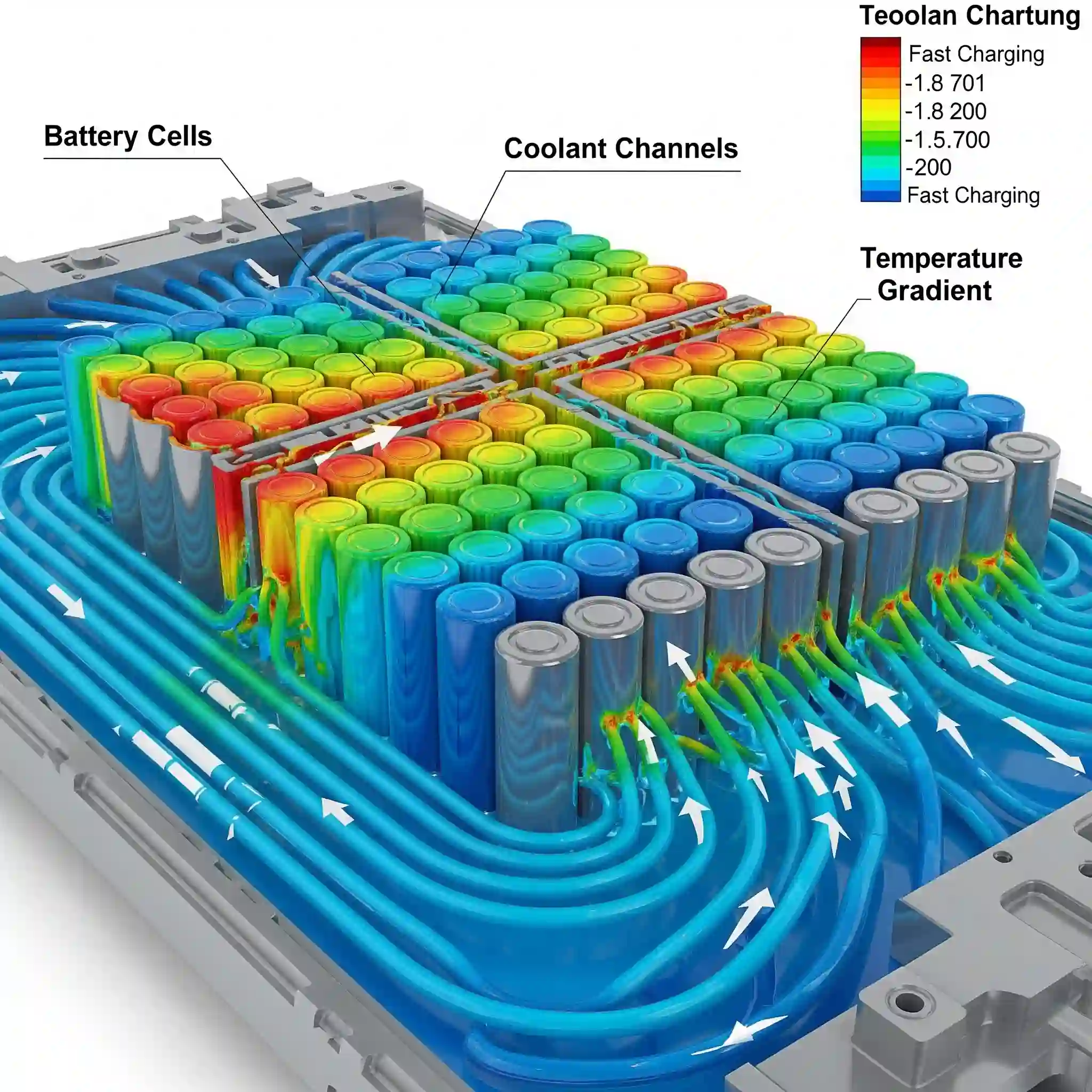

- Fluid-Structure Interaction (FSI): Simulating a heart valve opening and closing, or wind causing a bridge to vibrate. The structural part is almost always FEM, so using it for the fluid part makes the coupling seamless.

- Porous Media Flow: Think groundwater flow or simulations inside a chemical reactor bed. FEM’s mathematical formulation often handles these problems more elegantly.

- Complex Multiphysics: When your fluid flow is tightly coupled with electromagnetics or chemical species transport, a multi-physics platform like COMSOL (which is FEM-based) is simply the king. 👑

We worked on a peristaltic pump where the fluid was pushed by a flexible tube being squeezed. The mesh had to deform significantly. FEM handled this deforming domain natively and with incredible grace. That’s a classic win for the Finite Element Method.

A Costly Mistake to Avoid: Choosing a Method Solely Based on Your Favorite Software

I’ve seen engineers waste weeks trying to force their favorite tool to solve the wrong problem. Being a wizard with Ansys Fluent (FVM) is great, but if you’re facing a complex FSI problem, you’re using a hammer to turn a screw. You might get it to work, but the results will likely be questionable.

The tool must serve the physics, not the other way around. This is why a core part of any CFD project is picking the right CFD software package for the specific challenge at hand, rather than just using what’s familiar.

The Future is Hybrid: Are the Lines Between FVM and FEM Blurring?

Honestly, yes. Things are getting interesting. Modern FVM solvers are now using polyhedral meshes, which have some geometric flexibility reminiscent of FEM elements. On the other side, some FEM formulations (like Discontinuous Galerkin) are being developed to be much better at handling conservation and shocks. The lines are definitely blurring, which is great for us engineers—it just means more powerful tools in the toolbox.

Your Project Demands the Right Approach. We Deliver It.

Ultimately, the solver method is just one piece of the puzzle. An accurate simulation depends on a clean CAD, a high-quality mesh, correct boundary conditions, the right physical models, and frankly, having the right hardware for CFD to run it all in a reasonable time.

The real value an expert brings isn’t just knowing how to click buttons in one software. It’s the ability to look at a complex industrial problem and map out the entire workflow, from choosing the method to validating the final number. This is precisely the kind of holistic view that an experienced fluid dynamics consultant provides, becuase a flawed approach can invalidate even the most powerful simulation.

So, after all this, the final verdict on the FVM vs. FEM debate isn’t about which one is universally “better.” The better method is the one that most accurately, efficiently, and robustly solves your specific engineering problem. The skill is in knowing how to choose.