1. Why Your Choice of Turbulence Model Can Make or Break Your CFD Simulation

Picking a turbulence model isn’t just another setting in a dropdown menu. It’s the decision that fundamentally tells your software how to handle the chaotic, swirling nature of fluid flow. Get it wrong, and you could be looking at results that are 20-30% off, or even completely misleading. This could mean designing a heat sink that overheats or an airfoil that stalls unexpectedly.

Before we get into the models themselves, if you’re just starting out, it’s worth having a solid grasp of the entire simulation workflow. We’ve laid everything out in our ultimate guide to what CFD is. But for now, just know that getting a grip on understanding turbulence models is one of the most crucial skills you can develop for accurate CFD.

2. What is Turbulence in CFD? A 2-Minute Practical Explanation for Engineers

Forget complex equations for a second. Think of the smoke rising from a candle. Initially, it’s a smooth, predictable line (laminar flow). Then, it erupts into a complex, unpredictable mess of eddies and swirls (turbulent flow). Simulating every single one of those tiny swirls (a method called DNS) would take a supercomputer months for even a simple problem.

That’s why we have turbulence models. They are clever mathematical shortcuts that don’t try to resolve every tiny eddy. Instead, they model the average effect of all that chaos on the main flow. This is what makes getting results for industrial problems possible within hours or days, not centuries.

3. Introducing the RANS Family: The Workhorse of Industrial CFD

The most common family of these models is called RANS (Reynolds-Averaged Navier-Stokes). Think of RANS models as the Toyota Corolla of the CFD world. They aren’t the flashiest, but they are incredibly robust, computationally cheap, and get the job done reliably for a huge range of engineering applications. For most of the projects you’ll encounter, a RANS model is your starting point.

4. The Big Three RANS Models: A Head-to-Head Comparison

Within the RANS family, you’ll constantly run into three specific names. Let’s break down what they actually do and where they shine.

4.1. The Standard k-epsilon (k-ε) Model: Best for Free-Shear & Fully Turbulent Flows

This is one of the oldest and most widely used models. Its strength lies in flows that are far from walls, like the wake behind a building, jets, or mixing layers. It’s robust and converges easily, which is why it became so popular.

However, it has a well-known weakness: it performs poorly in the critical area right near a surface, the boundary layer. It uses something called “wall functions” to bridge this gap, which can be inaccurate if your flow is complex or involves separation.

4.2. The k-omega (k-ω) Model: The Specialist for Wall-Bounded & Low-Reynolds Flows

The k-omega model is the opposite. It was specifically designed to be brilliant at resolving flow right at the wall. It’s the go-to choice for detailed aerodynamic analyses where things like pressure gradients and flow separation are critical. It gives you a much more accurate prediction of wall shear stress and heat transfer.

The catch? It’s incredibly sensitive to your mesh quality, especially a parameter called y+. Nail the mesh, and it works beautifully. Mess it up, and the solution can diverge. If these terms are new, we highly recommend reading our guide explaining CFD meshing concepts like Y+.

4.3. The k-omega SST Model: The Hybrid Solution We Often Recommend at CFDSource

This is where things get interesting. The SST (Shear Stress Transport) model is a clever hybrid. It uses the k-omega model in the near-wall region (where it’s strongest) and smoothly transitions to the k-epsilon model further away from the surface (where it’s more stable). 💡

I remember an automotive aerodynamics project a few years back where we were analyzing a new side mirror design. The standard k-epsilon model completely missed a small, persistent vortex that was generating a ton of noise. The standard k-omega model struggled to converge. Switching to k-omega SST not only gave us a stable solution but it captured that exact vortex, and the results finally matched our experemental wind tunnel data. It’s this versatility that makes SST our default choice for many complex external and internal flow problems.

5. Decision Matrix: Which Turbulence Model Should You Choose for Your Project?

Okay, let’s put it all together in a simple table. This isn’t a substitute for engineering judgment, but it’s a fantastic starting point.

| Application / Flow Type | Recommended Model | CFDSource Pro-Tip |

| External Aerodynamics (Cars 🚗, Airfoils) | k-omega SST | Absolutely critical to get the Y+ value less than 1 for accurate drag and lift prediction. |

| Internal Flow (Pipes, Valves, Ducts) | k-epsilon (Realizable) | A good, robust starting point. If there are strong swirl or separation zones, consider SST. |

| Heat Transfer / HVAC | k-omega SST | SST is generally better at predicting heat transfer at the walls, which is often the entire point! |

| Jets & Mixing Layers | Standard k-epsilon | This is the classic application where k-epsilon was designed to perform well. It’s efficient here. |

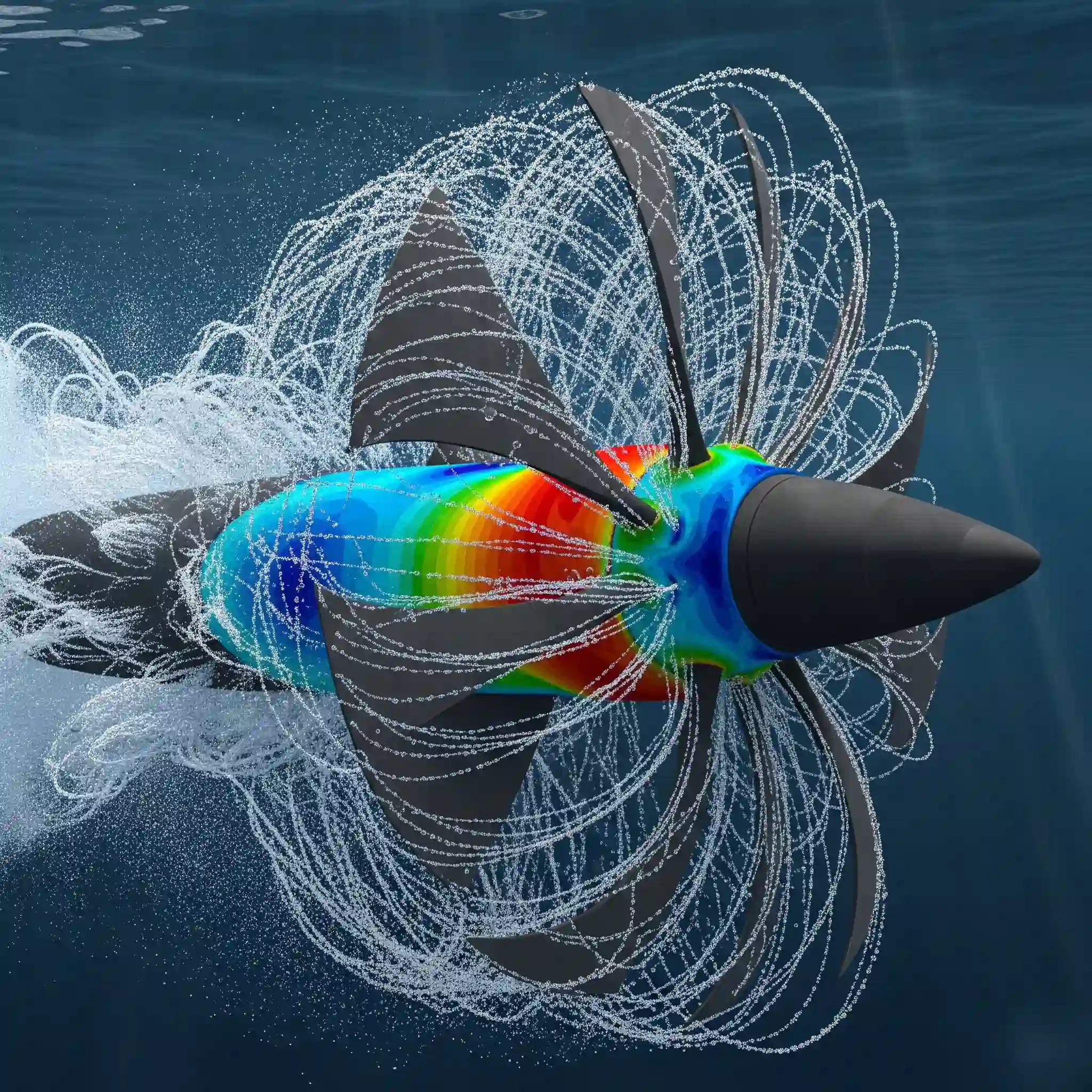

| Turbomachinery (Pumps, Turbines) | k-omega SST | The complex flow behavior on blades almost always benefits from the SST model’s hybrid approach. |

If your project doesn’t fit neatly into these boxes, or if the cost of an inaccurate simulation is high, that’s where targeted expertise comes in. Choosing the right model and its settings is a core part of our CFD consulting service where we tailor the approach to your specific physics.

6. Beyond Theory: Implementation in Ansys Fluent & The Critical Role of y+

Knowing the theory is one thing, but making it work in your software is another. When you select a model like k-omega SST in your solver, you’re also making an implicit promise about your mesh. Specifically, you’re promising that your mesh is fine enough near the walls to capture the physics that the model was designed for.

6.1. It’s Not Just the Model, It’s the Mesh: Why Your y+ Value Dictates Your Success

I can’t tell you how many times a promising simulation has produced junk results simply because of a poor mesh near the wall. The key metric here is y+. Think of it as a non-dimensional distance that tells you how fine your first layer of mesh cells is. For wall-resolving models like k-omega SST, you absolutely must have a y+ value of ~1. For models using wall functions (like standard k-epsilon), you need it to be in the 30-300 range. Getting this wrong is like trying to measure a microbe with a yardstick.

And of course, a good mesh can only be built on a clean CAD model. If you’re struggling with errors before you even get to meshing, you might want to review some best practices for preparing your geometry for CFD analysis.

7. Common Pitfalls: 3 Mistakes We’ve Seen in Industrial Projects

After years in this field, you start to see the same mistakes pop up. Here are a few that can quietly sabotage your results:

- “Set it and Forget it” Mentality: Choosing a model and leaving all the advanced settings on default. Sometimes this works, but for complex flows involving things like curvature or rotation, the default constants might not be appropriate.

- Ignoring the Inlet Conditions: Your turbulence model needs to know how turbulent the flow is at the start. Simply setting a velocity isn’t enough. You need to provide realistic values for turbulent intensity and length scale. This is just as important as choosing the right boundary conditions for your outlets and walls.

- Fighting for Convergence at All Costs: Sometimes, a simulation that won’t converge isn’t a failure—it’s telling you something. It might be that the flow is naturally unsteady (vortex shedding, for example) and your steady-state RANS model is struggling to find a single, average solution. Before you spend days tweaking settings, it’s crucial to understand what convergence in CFD actually means and how to interpret the residuals.

8. When RANS Isn’t Enough: A Brief Look at Advanced Models (LES & DES)

RANS models are fantastic, but they have a fundamental limitation: they average out the turbulence over time. What if you actually need to see those chaotic, time-varying eddies? This is crucial for applications like aeroacoustics (predicting noise 🔊) or detailed combustion analysis.

This is where more advanced (and computationally expensive) models like Large Eddy Simulation (LES) and Detached Eddy Simulation (DES) come in. These models resolve the larger turbulent structures and model only the smallest ones. They provide a staggering level of detail but require significantly more computing power and expertise. This is the kind of high-fidelity work where partnering with a specialized fluid dynamics consultant becomes essential.

9. The Final Step: How We Validate Our Simulation Results at CFDSource

A simulation is just a collection of colorful pictures until you can prove it reflects reality. Validation is non-negotiable. For every important project, we comapre our results against a benchmark. This could be experimental data from a wind tunnel, empirical correlations from a textbook, or published results from a peer-reviewed scientific paper.

This step is where you truly earn your confidence in the results. It’s where you stop looking at contour plots and start making real engineering decisions. A huge part of this is knowing how to effectively analyze your data, which is a skill in itself. We’ve got a great primer on how to visualize and interpret your CFD results that covers the basics of turning raw data into actionable insights.

10. Conclusion: From Beginner to an Informed Decision-Maker

Choosing a turbulence model doesn’t have to be a black box. By understanding the fundamental strengths and weaknesses of the main RANS models—k-epsilon for flows away from walls, k-omega for flows at the wall, and SST as the versatile hybrid—you’re already ahead of the curve.

Remember, the model is a tool, and its effectiveness is tied directly to your mesh quality (hello, y+!) and your understanding of the underlying physics. With the right approach, you can move from guessing to making informed, defensible engineering choices.

11. Your Next CFD Project Starts Here

We live and breathe this stuff. While this guide gives you the fundamentals for understanding RANS turbulence models, every project has its own unique quirks and challenges. If you’re tackling a problem where accuracy is paramount and you need to get it right the first time, our team has the deep-seated experience to guide you. Explore our case studies to see how we’ve solved complex fluid dynamics problems for industries worldwide.