So you’ve run your simulation. The contours look stunning, the streamlines are flowing beautifully, and you finally got that stubborn solution to converge. Great. But what does it actually mean? If you’re new to the field, you might find our foundational guide on what CFD is and how it works a useful starting point.

Because here’s the hard truth: without validation, your colorful results are just educated guesses. They might be right, or they could be dangerously wrong. This guide is about closing that gap between a pretty picture and a reliable engineering tool. We’re going to walk through how to validate your CFD results so you can present them with confidence.

Why Your CFD Simulation is Just a “Pretty Picture” Without Proper Validation

Look, I’ve been in this game for over 15 years, and I’ve seen it happen. I remember a project early in my career involving a new heatsink design for a high-power electronics board. The CFD looked perfect—beautiful temperature gradients, ideal airflow. We were confident. But when the physical prototype was tested, a critical component fried itself in under 10 minutes. 🔥

The simulation was wrong. A subtle error in defining the thermal contact resistance between the chip and the heatsink threw everything off. That expensive lesson taught me that validation isn’t an academic checkbox; it’s the most critical step in risk management for any engineering project. It’s what separates a CFD user from a CFD expert.

The Foundational Step: Sourcing High-Quality Experimental Data

Before you can compare anything, you need a benchmark—a source of truth. Finding good experimental data is half the battle. Your goal is to find data from an experiment that is as close as possible to your simulation case. Don’t just grab the first paper you find on Google Scholar.

Leveraging Academic Papers & Textbooks for Classic Benchmarks

For foundational skills, you can’t beat the classics. Cases like flow over a cylinder, the backward-facing step, or the Ahmed body are documented extensively in fluid dynamics literature. These are fantastic because thousands of researchers have already simulated them, providing a massive pool of data for comparison. They’re the ‘hello, world’ of CFD validation and perfect for sanity-checking your own methods and avoiding some of the common CFD pitfalls for beginners.

Accessing Public Databases and Wind Tunnel Test Results

For more complex industrial applications, academic papers might not cut it. Fortunately, organizations like NASA and ERCOFTAC maintain public databases with high-fidelity experimental data specifically for CFD validation. NASA’s Turbulence Modeling Resource, for example, is an incredible goldmine for aerodynamic cases. It’s raw, reliable data you can trust.

The Golden Rule: Your Simulation Setup MUST Mirror the Experiment

This sounds obvious, but it’s where most validations fail. You cannot simulate a 2D airfoil and compare its lift coefficient to 3D wind tunnel data that includes wingtip vortices. Every single detail matters. You have to become a detective and reconstruct the exact experimental conditions within your CFD software, whether it’s Ansys Fluent, OpenFOAM, or something else. This attention to detail is often what separates a quick analysis from a thorough one provided by a professional Fluid Dynamics Consultant.

A Checklist for Matching Boundary Conditions, Fluid Properties, and Geometry

To get this right, you need a methodical approach. Don’t just eyeball it. I recommend using a checklist to ensure you’ve covered all your bases.

| Parameter | What to Check in the Experiment | Where to Set it in CFD |

| Geometry | Are the exact dimensions, including small details like fillets or chamfers, reported? | Import/create a CAD model with identical dimensions. Don’t simplify unless you can justify it. |

| Inlet Conditions | What was the inlet velocity profile? Was it uniform or fully developed? Temperature? Turbulence intensity? | Set your inlet boundary condition type and values to match precisely. |

| Fluid Properties | Were properties like density (ρ) and viscosity (μ) constant or temperature-dependent? | Define your material properties. Use a polynomial function for temperature-dependence if necessary. |

| Wall Conditions | Was the wall smooth or rough? Was there a no-slip condition? Was it a specific temperature or heat flux? | Apply the correct wall boundary condition (e.g., No-Slip, Wall Roughness, Fixed Temperature). |

Why Your Turbulence Model Choice (e.g., k-ω SST vs. k-ε) is Critical for Accurate Validation

Choosing the wrong turbulence model is like using a screwdriver to hammer a nail. It might work, but the result won’t be pretty. If the experimental case involves flow separation or significant adverse pressure gradients, a standard k-ε model will likely give you inaccurate results. You need match the physics.

For instance, the k-ω SST model is generally superior for capturing the near-wall behavior in boundary layers, which is crucial for predicting drag and separation. Its’ importance cannot be overstated. The choice of model is deeply connected to the underlying mathematics of your solver, which is why understanding the differences between FVM and FEM can also provide a deeper insight into potential sources of error.

The Art of Comparison: Key Metrics for Quantitative & Qualitative Validation

Okay, so you have your experimental data and a simulation that mirrors the setup. Now for the moment of truth. Comparing them isn’t just about saying “they look similar.” It’s an art form that blends hard numbers with engineering intuition.

Quantitative Analysis: Plotting Profiles, Comparing Coefficients (C_L, C_D), and Calculating Error Margins

This is the numbers part. Don’t just look at the final value for lift (C_L) or drag (C_D). Plot it. Extract data along a line or surface in your simulation (like the pressure distribution over an airfoil) and plot it on the same graph as the experimental data points. This visual comparison is powerful.

Then, calculate the percent error for key integrated values. A 5% difference in drag might be fantastic for a highly complex external aerodynamics case, while a 1% error might be expected for simple pipe flow. There’s no universal “good” number; it all depends on the problem’s complexity and the stakes involved.

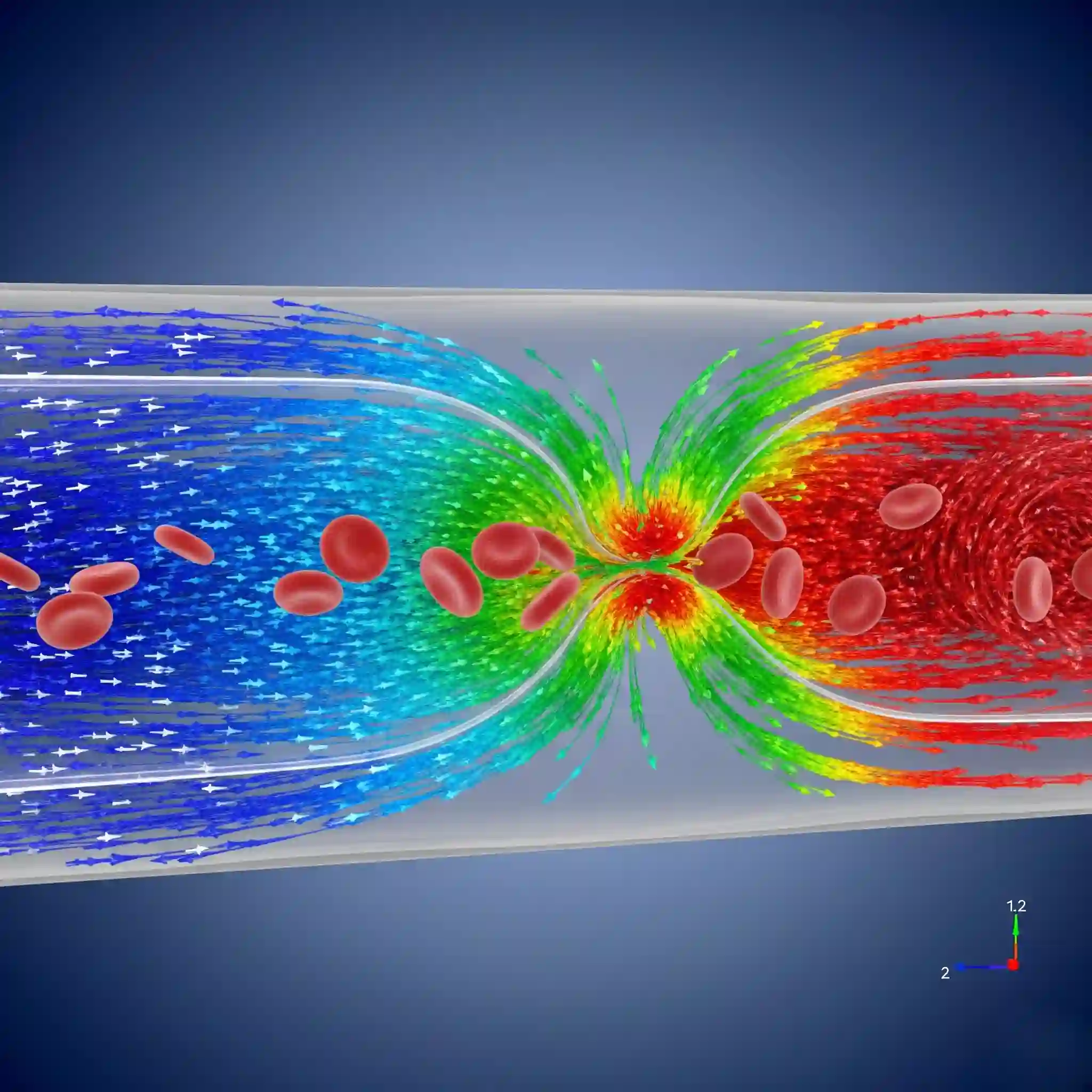

Qualitative Analysis: Visually Matching Flow Structures like Vortices and Shockwaves

Sometimes, the most important insights aren’t in the numbers but in the physics. Place your simulation’s contour plot next to an experimental image (like a Schlieren photograph or PIV data). Are the flow structures the same? 🧐 Is the vortex shedding frequency correct? Is the shockwave located on the right spot on the wing? If these qualitative features match, it’s a huge sign that your simulation is capturing the correct physics, even if there are minor numerical discrepancies.

What If Your Results Don’t Match? A Troubleshooting Guide by CFDSource Experts

It happens. In fact, it’s rare for results to match perfectly on the first try. A mismatch isn’t a failure; it’s a diagnostic tool. When our clients bring us a simulation that doesn’t align with their real-world tests, we start by checking a few usual suspects.

Investigating the Usual Suspects: Mesh Quality (y+), Solver Settings, and Physical Assumptions

This is our go-to troubleshooting list. 90% of validation problems can be traced back to one of these:

- The Mesh: This is almost always the first suspect. Is your mesh fine enough in critical areas? Is the y+ value appropriate for your turbulence model’s wall treatment? A coarse mesh is the number one cause of inaccurate results. Sometimes, the only barrier to a better mesh is hardware. Making sure you have the right workstation for CFD is a seperate but equally important battle.

- Solver Settings: Did your solution truly converge? Don’t just trust the solver’s default criteria. Monitor key values like drag or mass flow rate to see if they’ve plateaued. Check your timestep for transient simulations; is it small enough to capture the physics (Courant number)?

- Physical Assumptions: Go back to your model setup. Did you assume the flow was incompressible when it’s actually hitting Mach 0.4? Did you neglect radiation in a high-temperature problem? Re-evaluating these fundamental choices is key.

No Experimental Data? The Professional’s Alternative: Verification Techniques

What if you’re designing something completely new? A novel turbine blade or a unique medical device for which no experimental data exists. This is a common challenge in R&D. In this case, we shift from Validation (comparing to reality) to Verification (ensuring the math is solved correctly).

The Gold Standard of Verification: Performing a Grid Convergence Study (GCI)

The most trusted verification method is the Grid Convergence Study, or GCI. The concept is simple: you run your simulation on at least three progressively finer meshes (e.g., a coarse, medium, and fine mesh, where each is roughly twice as dense as the last). You then check if your key output (like pressure drop) is trending towards a consistent value. If the answer stops changing as the mesh gets finer, you can be confident that your result is independent of the mesh resolution.

The CFDSource Validation Protocol: Our Commitment to Decision-Ready Results

For us, validation isn’t an afterthought; it’s built into our workflow. When a company engages us for our CFD consulting services, they’re not just buying simulation hours; they’re buying confidence in the results. Our internal protocol involves defining clear acceptance criteria with the client before we even start the simulation, followed by a rigorous validation or verification step. The final report doesn’t just show contours; it proves why the results are trustworthy.

From Raw Data to Boardroom-Ready: How to Present Your Validation Findings

Your job isn’t done until you’ve communicated your findings effectively. Don’t just dump a bunch of plots into a PowerPoint.

Create clear, well-labeled graphs that overlay simulation data (as a line) with experimental data (as points with error bars). A summary table showing the key quantities, experimental values, simulation values, and the percentage error is incredibly effective for management. The post-processing tools in some of the best commercial CFD packages make this step quite easy.

Ready to Move from Simulation to Certainty?

Validation is the bridge between a computational exercise and a reliable engineering decision-making tool. It can be intimidating, but it’s a non-negotiable skill for anyone serious about CFD. By methodically sourcing data, mirroring experimental setups, and rigorously comparing your outputs, you build the confidence needed to stand behind your work. Ultimately, validating your CFD results properly is what transforms your simulation from a pretty picture into a powerful instrument for innovation.