Why Your Choice of Combustion Model Can Make or Break Your CFD Simulation

Let’s get straight to it. Picking the wrong combustion model isn’t a small academic mistake; it’s the difference between a design that works and a project that wastes weeks of computational resources only to produce garbage results. Getting advanced combustion modeling right is one of the most challenging aspects of CFD, a topic we explore across many fields in our deep dive into modern simulation techniques. Your model choice directly impacts everything from predicted flame temperature and emissions to whether your simulation even converges at all.

The Foundation: Understanding Turbulence-Chemistry Interaction (TCI)

Before we compare models, we have to talk about the core problem: Turbulence-Chemistry Interaction, or TCI. Imagine trying to light a match in a hurricane. The turbulence messes with the flame, and the heat from the flame messes with the turbulence. That’s TCI. All combustion models are essentially different attempts to simplify this ridiculously complex relationship. In high-speed systems, this interaction becomes even more violent, a challenge we often see when [simulating supersonic and hypersonic flows]. It’s a constant battle between fluid mixing rates and chemical reaction rates.

The Workhorse Model: When is the Eddy Dissipation Model (EDM) Good Enough?

The Eddy Dissipation Model (EDM) is often the first model engineers reach for. It’s robust, it’s relatively easy to set up, and it converges well. But its simplicity is also its biggest weakness.

How EDM Simplifies Reality: The “Infinitely Fast Chemistry” Assumption

EDM operates on one huge simplification: it assumes chemistry is infinitely fast. In other words, the moment fuel and air mix at the molecular level, they burn instantly. The model says the speed of the reaction is controlled only by the turbulent mixing rate (the ‘eddy dissipation’). For some problems, this is a perfectly reasonable assumption.

Ideal Use Cases: When to rely on EDM for fast, reliable results

We use EDM all the time, but only when we’re confident its assumptions hold. It’s generally a safe bet for:

- Large-scale industrial furnaces where the flow is highly turbulent and non-premixed.

- Simple diffusion flames where you primarily care about the overall heat release and not minor species.

- Initial design iterations to get a quick, qualitative feel for the flow field before committing to a more expensive model.

The Critical Limitations: Where EDM Fails and Why It Could Mislead Your Design

Here’s where trouble starts. I’ve seen projects where EDM predicted a perfectly stable, efficient flame, but the real-world prototype was suffering from constant flameouts and producing heaps of carbon monoxide. Why? Because the chemistry was actually quite slow, and EDM was completely blind to it. It cant predict effects like flame extinction, ignition delay, or pollutant formation (like NOx) because it has no detailed chemical kinetics. If your results look ‘too perfect’ or dont match reality, it might be time for professional CFD analysis services to review the physical models.

The High-Fidelity Approach: Unpacking Flamelet Generated Manifolds (FGM)

This is where things get really interesting. Flamelet models, particularly Flamelet Generated Manifolds (FGM), take the opposite approach. Instead of simplifying the chemistry to nothing, they try to handle it in a very clever way.

Decoupling Chemistry from Flow: The Core Concept Behind Flamelet Models

The magic of FGM is that it decouples the complex chemistry from the complex fluid flow calculation. Think of it like this: you pre-calculate all the detailed chemical reactions (hundreds of species and reactions) in a separate, simplified 1D flamelet problem. The results are stored in a massive lookup table (a ‘manifold’). The main CFD solver then just looks up the chemical state (like temperature, species concentration) from this table during the flow simulation, instead of solving the chemical equations everywhere.

From Pollutant Prediction (NOx, Soot) to Flame Extinction: The Power of Detailed Chemistry

Because you’ve done the hard chemistry work upfront, you can now accurately predict things that are impossible with EDM. This includes thermal NOx formation, soot, and critical phenomena like flame lift-off and extinction. This level of detail is also what allows you to start investigating secondary effects, like the combustion noise that’s a major headache in [aeroacoustics engineering]. It’s a game-changer for high-performance applications where small details matter.

Head-to-Head: A CFDSource Comparison of EDM vs. Flamelet Models

So, which one should you choose? 🤔 There’s no single answer, only trade-offs. We’ve put together a quick comparison table based on our experience with dozens of industry projects. It’s the same mental checklist our engineers run through.

| Feature | Eddy Dissipation Model (EDM) | Flamelet Generated Manifold (FGM) |

| Accuracy | Low to Moderate | High |

| Computational Cost | Low | High (but less than full transport) |

| Setup Complexity | Low (Plug-and-play) | Very High (Requires expertise) |

| Predicts Pollutants? | No | Yes (NOx, Soot, CO) |

| Predicts Extinction? | No | Yes |

| Best For… | Fast turnarounds, basic heat release | Detailed design, R&D, emissions studies |

Our rule of thumb at CFDSource is this: if you need to answer “how hot does it get?”, start with EDM. If you need to answer “why is it producing so much NOx and is the flame stable?”, you need to be looking at Flamelet models. It’s that fundamental a difference.

Practical Implementation: Common Pitfalls and Expert Tips from Our Engineers

Theory is one thing, but getting these models to actually run without crashing is a whole other beast. Both EDM and FGM have their own unique ways of failing, and after years of debugging, you start to see the same patterns repeat. It’s less about knowing the equations and more about knowing the personality of the solver.

For Flamelet Users: 3 Common Mistakes in Generating Your PDF Table and How to Avoid Them

Generating the flamelet table is where most FGM simulations go wrong before they even begin. It’s an art. Here are the three most common traps I see:

- Using an Overkill Chemical Mechanism: I once saw a project where the engineer used a massive, 1500-species mechanism to model a simple methane flame. The table took two weeks to generate and was huge. A validated, reduced mechanism with 50 species would have given the same answer in a few hours. Always start with the simplest validated mechanism for your fuel.

- Wrong Scalar Dissipation Rate Range: The scalar dissipation rate is basically a measure of flame stretch. If you set the range for this in your table generation too narrow, and your CFD simulation experiences higher stretch rates, the solver will try to look up a value that doesn’t exist. The result? A fatal “floating-point exception” error. Always run a quick, coarse simulation first to estimate the range of stretch your flame will actually experience.

- Ignoring Table Interpolation Errors: The FGM table is discrete. The solver is constantly interpolating between points. If your table isn’t fine enough, you can introduce significant errors, especially for minor species like CO. It’s a balance; a finer table is more accurate but also larger and slower to read from.

Troubleshooting Convergence: Why Your Advanced Combustion Simulation Won’t Converge (and a CFDSource Checklist to Fix It)

We’ve all been there. Staring at a residuals plot that looks like a seismograph during an earthquake. 📉 When your combustion simulation diverges, dont just lower the under-relaxation factors and pray. Work through a checklist:

- Mesh, Mesh, Mesh: Is your mesh quality (skewness < 0.8) good enough in the reaction zone? Do you have enough cells to resolve the flame front? This is the #1 killer of combustion simulations.

- Start Simple: Don’t try to start a complex FGM simulation from scratch. Get a solution to converge with a simpler model first (like a non-reacting flow, then EDM), and use that as your initial condition.

- Check Your Boundaries: Are your inlet turbulence values realistic? Is there an accidental backflow at your outlet? A small error here can wreck the entire solution.

- Energy Equation: Sometimes, it’s the energy equation that diverges. Try solving with a fixed temperature first to ensure the flow field is stable before enabling the energy and reaction models.

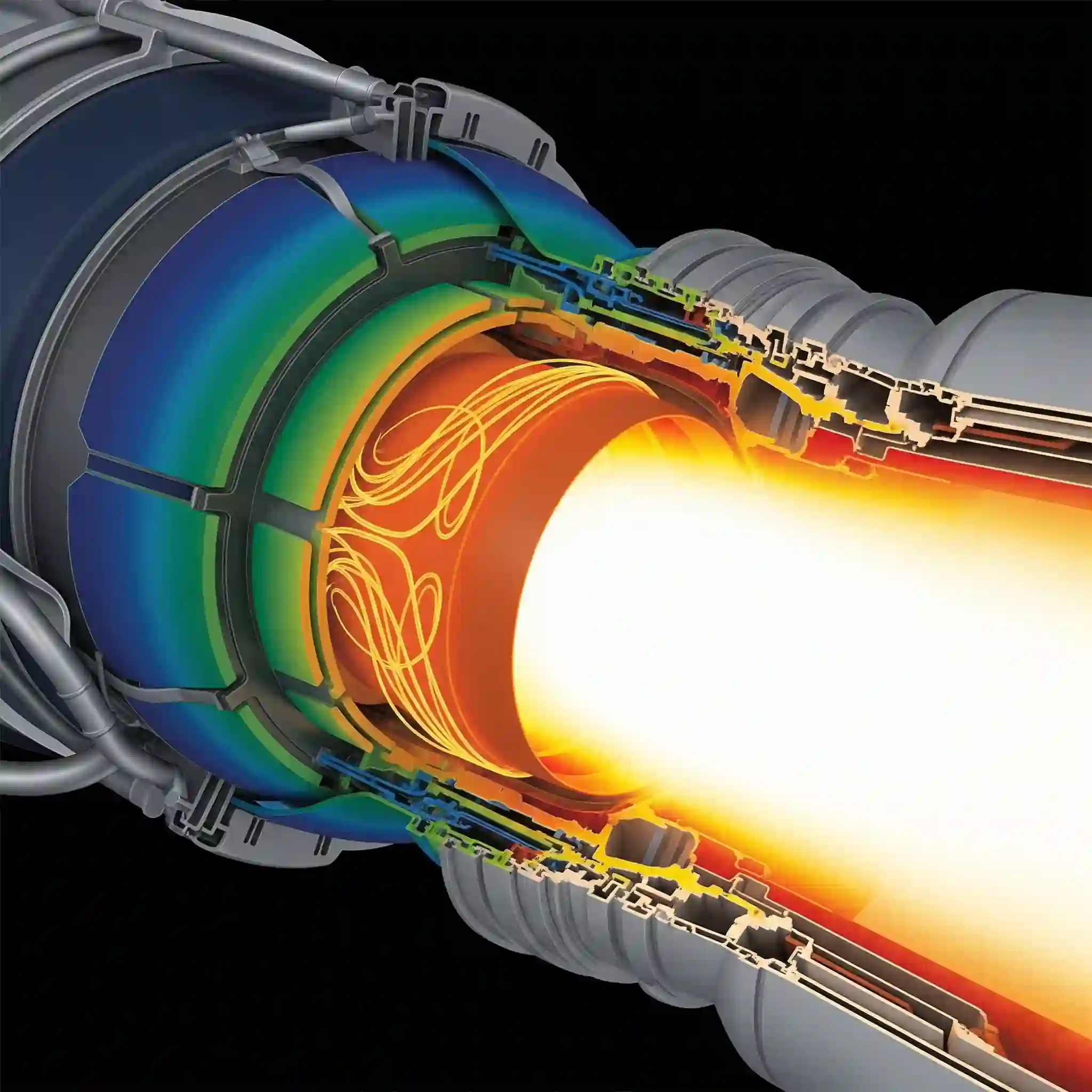

Real-World Application: How CFDSource Optimized an Industrial Gas Turbine Using the FGM Model

A few years ago, a client came to us with a gas turbine combustor that was failing emissions tests for NOx. Thier in-house EDM simulations showed perfect combustion, but reality disagreed. We built a custom FGM setup for them, and the simulation immediately revealed a small, intense recirculation zone near the fuel injector that was creating a hot spot—a perfect breeding ground for thermal NOx. The detailed chemistry allowed us to see what was happening. This insight led to a minor redesign of the injector swirl angle, which not only cut NOx by 30% but also reduced the risk of coupled [fluid-structure interaction effects] caused by pressure oscillations.

Is There a Middle Ground? A Quick Look at Partially Premixed Combustion Models

What if your flame isn’t purely non-premixed or premixed? This is common in gas turbines and IC engines. Models like the C-Equation or the Extended Coherent Flame Model (ECFM) offer a middle ground. They try to track the mixing front and apply different physics depending on whether the mixture is flammable or not. It’s about picking the right tool for the fluid’s state, whether it’s a reacting gas or one of the many [complex non-Newtonian fluids] we model in other industries. These models add another layer of complexity but can be invaluable for specific applications.

The Future: When to Consider LES for Combustion Modeling

For the ultimate in accuracy, there’s Large Eddy Simulation (LES). Unlike RANS models that average out all turbulence, LES resolves the large, energy-carrying eddies and models the small ones. For combustion, this means you can actually see the flame wrinkling and flapping in real-time. The downside? The computational cost is astronomical. But it’s the gold standard for studying highly transient phenomena like flame instability or [predicting cavitation in hydraulic machinery]. As GPU computing gets cheaper, LES will become more common in industry, but for now, it’s mostly a research tool.

Choosing the Right Partner for Your Combustion Challenge

At the end of the day, these models are just tools. The real value comes from the engineer wielding them. The ability to choose the right model, set it up correctly, and interpret the results is what separates a successful project from a failed one. When you’re looking for help and vetting potential [CFD analysis companies], ask them why they’re choosing a particular model. If they cant give you a clear, physics-based reason, that’s a red flag. Ultimately, success in advanced combustion modeling comes down to experience and a deep understanding of the underlying physics.