Anyone who’s spent weeks wrestling with a non-converging simulation knows the feeling. You’re up against the computational wall. It’s a familiar story for any CFD professional: the finer the mesh, the longer the solve time, the higher the hardware cost. We’ve been pushing the boundaries of traditional methods for decades, but for some problems, we’re simply running out of road. This is just one of the topics we are exploring in our deep dive into modern simulation techniques.

But something is shifting. We’re now seeing the rise of physics-informed neural networks (PINNs) and AI in CFD not as a far-off academic concept, but as a practical tool that can crack problems we once considered unsolvable.

The Computational Wall: Why Traditional CFD Methods Are Reaching Their Limits

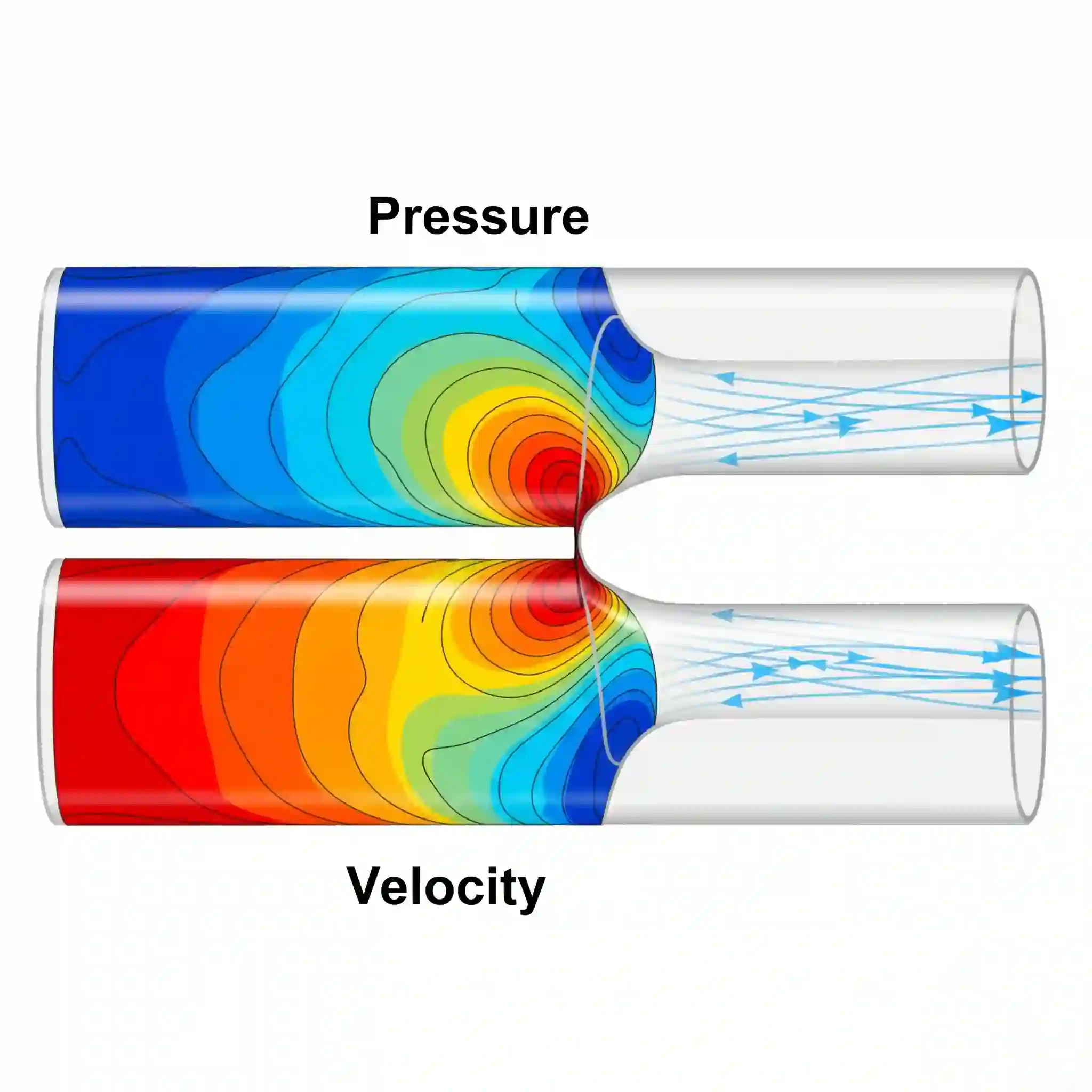

Let’s be honest. The FVM and FEM solvers we rely on are incredible feats of engineering, but they have their baggage. The biggest one? The mesh. Creating a high-quality, body-fitted mesh for a complex geometry can consume 70% of a project’s timeline. Then comes the solve time itself, which, for large-scale transient simulations, can mean tying up an expensive HPC cluster for days or even weeks. It’s a bottleneck that directly impacts time-to-market and R&D budgets.

This isn’t just about speed, it’s about scope. Parametric studies involving hundreds of design variations are often financially unfeasible with traditional methods. We need a way to get answers faster without sacrificing the underlying physics.

What Are Physics-Informed Neural Networks (PINNs)? A Practical Explanation for Engineers

Forget the typical “black box” AI that just learns from input-output data. A PINN is different. It’s a neural network that is taught the laws of physics during its training.

Think of it this way: instead of just showing the network a bunch of simulation results and asking it to find a pattern, we force the network’s output to satisfy the governing partial differential equations (PDEs)—like the Navier-Stokes equations—directly. The “physics” part is baked into its learning process. This means it doesn’t need massive datasets to produce physically consistent results.

Beyond Black Boxes: How PINNs Encode Physical Laws (PDEs) Directly into the AI Model

So how does it work under the hood? Essentially, the loss function of the neural network has an extra term. Alongside the usual term that measures the error against known data points (like boundary conditions or sensor data), there’s a “physics residual” term. This new term penalizes the network anytime its prediction violates the governing PDE. The network is therefore forced to find a solution that not only fits the data but also obeys the fundamental laws of fluid dynamics or heat transfer.

Data-Driven vs. Physics-Informed: A Key Distinction

A purely data-driven model is like a student who only memorizes answers for an exam. It can be accurate if it has seen a similar question before, but it has no real understanding and fails on new problems.

A PINN, however, is like a student who understands the underlying theory. It can work with sparse, noisy, or incomplete data because it’s always guided by the physics. This makes it incredibly powerful for real-world engineering scenarios where perfect data is a luxury we rarely have.

Head-to-Head: Traditional Solvers (FVM/FEM) vs. PINNs – A CFDSource Breakdown

To make this tangible, here’s a quick comparison based on what we’ve seen in our projects.

| Feature | Traditional Solvers (e.g., ANSYS Fluent) | Physics-Informed Neural Networks (PINNs) |

| Meshing | Mandatory, often painful. Can be a major bottleneck. | Mesh-free. Evaluates the solution at any point in space. |

| Computational Cost | High during every run (inference). | High during training (one-time cost), extremely fast during inference. |

| Data Requirement | Needs well-defined boundary conditions. | Flexible. Can work with sparse data or even just teh BCs. |

| Inverse problems | Very difficult. Requires many iterative forward simulations. | Handled naturally and efficiently. A core strength. |

4 Game-Changing Applications Where PINNs Outperform Traditional CFD

This isn’t just theory. The unique strengths of PINNs unlock capabilities that are either impossible or wildly impractical with conventional solvers. These advancements often go hand-in-hand with leveraging high-performance computing (HPC) for large simulations, but the approach is fundamentally different.

Application 1: Inverse Problems – Identifying Material Properties or Boundary Conditions from Sensor Data

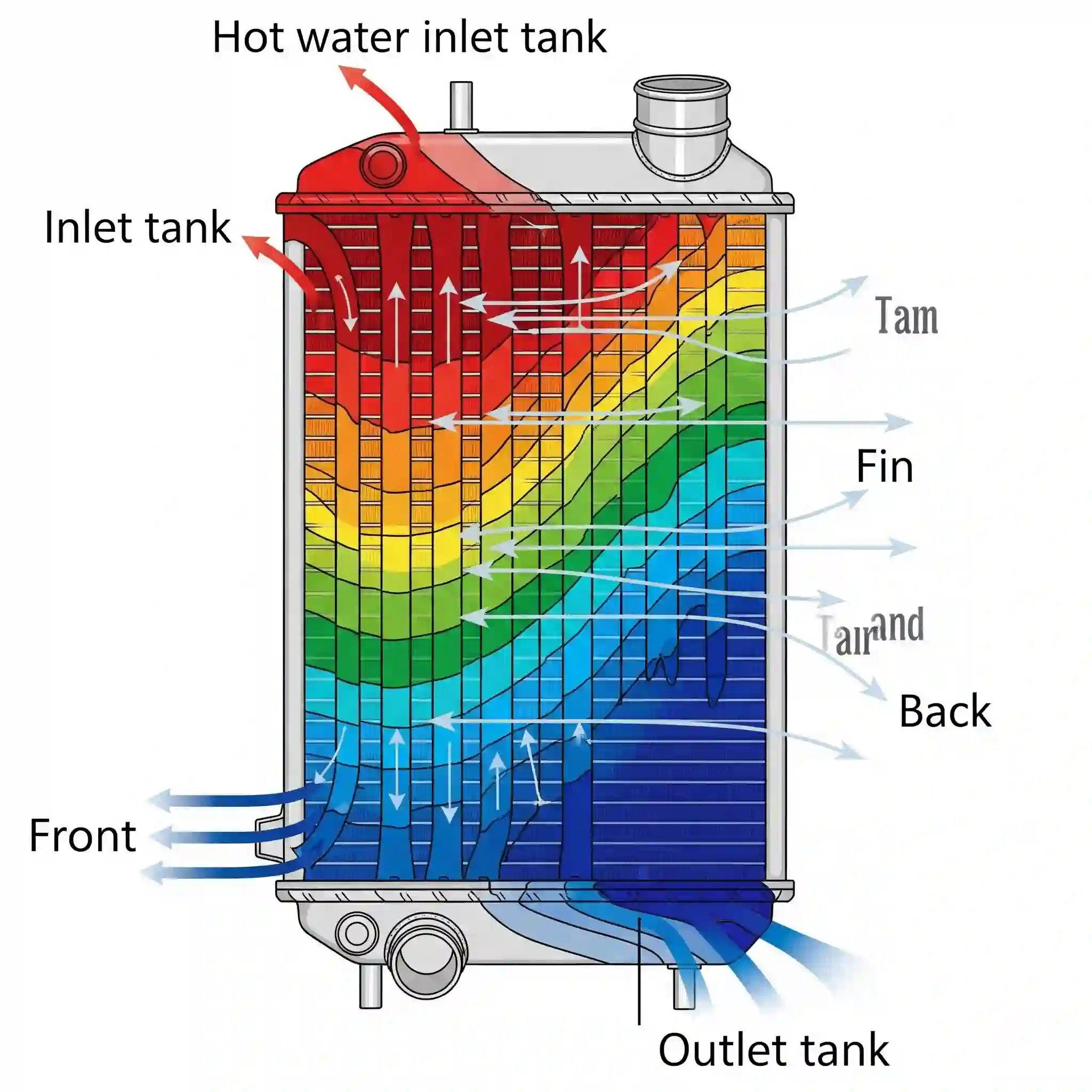

This is where PINNs truly shine. I remember a project a decade ago, part of my 15 years in this field, trying to identify an unknown heat source on a complex circuit board using only a handful of thermocouple readings. It took weeks of manual, iterative simulations, tweaking the heat source location and magnitude until the results matched the sensor data. It was a grind.

A PINN solves this directly. You feed it the sparse sensor data and the governing heat equation, and it deduces the unknown heat source as part of its training process. What took us weeks could now be solved in a matter of hours.

Application 2: Real-Time Surrogate Models – Accelerating Product Design and Creating Digital Twins

Once a PINN is trained, it’s lightning-fast. I’m talking milliseconds for a prediction that would take a traditional solver hours. 🚀 This lets you build a surrogate model—an AI-powered replica of your full CFD simulation. Engineers can use this model in real-time, changing design parameters like inlet velocity or geometry on the fly and seeing the results instantly. This completely changes the game for design optimization and is a key step towards building functional digital twins. The ability to accelerate the design cycle this dramatically is a core part of what we offer through our CFD analysis services.

Application 3: High-Dimensional Parametric Studies – Optimizing Designs Orders of Magnitude Faster

Anyone who’s tried to optimize a design with, say, five or more variables knows the “curse of dimensionality.” The number of simulations you need to run just explodes. With traditional methods, you’re forced to narrow your scope, potentially missing the true optimal design.

PINNs flip this on its head. After the initial training, exploring the entire design space is practically free. You can run tens of thousands of “virtual simulations” in minutes, generating performance maps that would have been unthinkable before. It allows for a more holistic approach to optimization, something we’re seeing change how products are fundamentally designed.

Application 4: Solving Problems with Incomplete Data – Where Traditional Solvers Fail

This is a big one. In the real world, we rarely have perfect information. Maybe you have a few pressure sensors inside a complex manifold, but you don’t know the exact flow profile at the inlet. A traditional solver would just stop, it needs all its boundary conditions defined.

A PINN, however, can often work with this. It uses the known physical laws (the PDEs) as a powerful constraint to infer the missing information. It essentially fills in the gaps in a physically plausible way. This moves CFD from a tool that only works in ideal conditions to one that can provide genuine insight into messy, real-world operational scenarios.

The Reality Check: Acknowledging the Current Challenges and Limitations of PINNs

Now, it’s not all magic. Anyone who tells you PINNs are a simple push-button solution is selling you something. This technology is still evolving, and being effective with it requires a healthy dose of realism and experience. It’s a powerful new tool in the toolbox, not a replacement for the entire toolbox.

The “Art” of Training: Dealing with Hyperparameters and Convergence Issues

Training a PINN can be tricky. It’s sensitive to things like the neural network architecture, the learning rate, and how you weight different parts of the loss function. Getting it wrong can lead to a model that simply doesn’t converge or gives nonsensical results. There’s a certain “art” to it that comes from experience, knowing how to diagnose a struggling model and nudge it in the right direction. It’s not as straightforward as setting up a case in Fluent.

When to Stick with Traditional Solvers: A Guide from Our Experts

So, when should you not use a PINN? For high-stakes, single-shot certification simulations where you need maximum fidelity and the result has to be legally defensible, stick with the battle-tested, validated codes. The methods for quantifying uncertainty in CFD predictions are far more mature in traditional solvers. PINNs are for exploration, acceleration, and solving previously intractable problems, not yet for signing off on a final design for regulatory approval.

The Future is Hybrid: Why Combining AI with ANSYS or OpenFOAM is the Ultimate Solution

The most exciting path forward isn’t about replacement, but integration. The future is hybrid. Imagine using a trusted OpenFOAM solver to generate a few high-fidelity data points, then using that data to train a PINN that can explore the entire design space around those points. Or using a PINN to provide a highly accurate initial guess for a traditional simulation, cutting its convergence time in half. This synergy is where the real power lies, and it’s central to the idea of creating a truly responsive CFD-powered digital twin of a real-world asset.

Is Your Project Ready for AI-Driven CFD? A 5-Point Checklist by CFDSource

Wondering if this technology is a good fit for your challenges? Ask yourself these questions:

- Repetition: Is your team running the same type of simulation over and over for different design parameters?

- Speed Bottleneck: Is the CFD turnaround time a major blocker in your R&D cycle?

- Inverse Problems: Do you need to determine unknown inputs (like material properties or heat loads) from measured outputs?

- Real-Time Need: Would the ability to get instant simulation feedback transform your design process?

- Data Overload: Do you have large amounts of simulation or experimental data that you’re struggling to turn into a predictive model?

If you answered “yes” to even two of these, exploring AI in CFD could unlock significant value for your organization. It represents a fundamental shift from single-shot analysis to continuous, intelligent prediction.