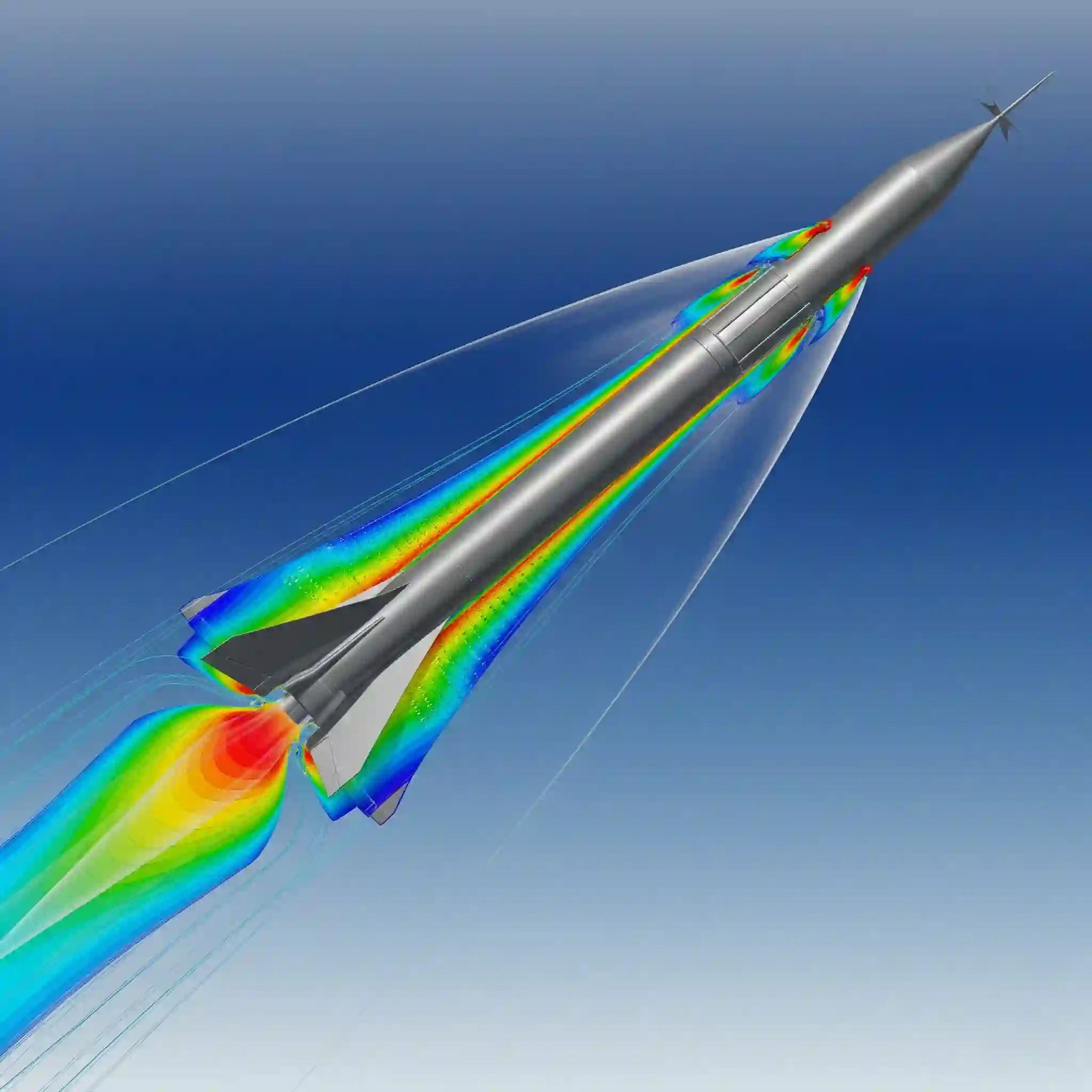

A colorful CFD plot can be impressively persuasive—or dangerously misleading. The difference lies not in the software, but in the expertise behind it. Anyone can generate an image, but making it reflect reality is another story entirely. This guide cuts through the ambiguity to give you a real engineer’s take on CFD accuracy. Before we dive deep, if you’re just getting started, it’s worth understanding the fundamentals in our [ultimate guide to Computational Fluid Dynamics].

The Billion-Dollar Question: What Does “Accuracy” Really Mean in CFD?

Look, when a client asks me “how accurate is this?”, they’re really asking “can I bet my project’s success on these results?”. The answer isn’t a simple percentage. Accuracy in CFD isn’t one single thing; it’s a balance. It’s about knowing what you need to get right and what you can afford to approximate.

Sometimes you need a number that’s within 2% of a lab test. Other times, you just need to know if a design change will make things better or worse. Defining the goal before you start the simulation is half the battle.

Qualitative vs. Quantitative Accuracy: Are You Matching Physics or Numbers?

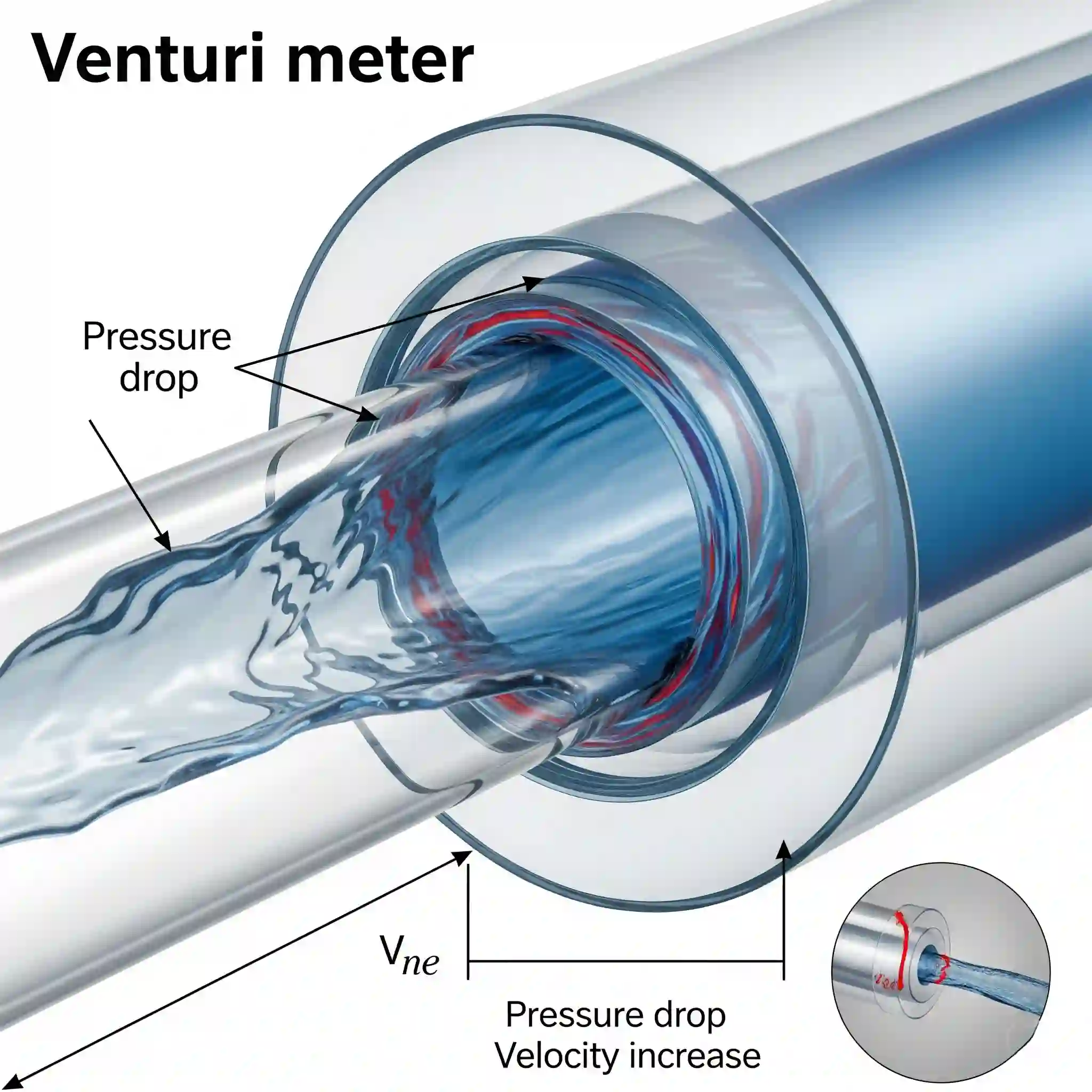

This is a crucial distinction. Quantitative accuracy is what most people think of: matching a pressure drop value to the third decimal place. It’s essential for things like valve sizing or pump performance curves.

But often, qualitative accuracy is the real prize. For example, are you correctly predicting the location of a hot spot on a PCB? Or capturing that critical vortex that’s causing vibration in a structure? Getting the flow behavior right can be far more valuable than hitting an exact number, especially in the early design stages. You need to know which one you’re chasing.

The Anatomy of Inaccuracy: Deconstructing the 3 Main Sources of CFD Error

If your simulation doesn’t match reality, the reason will almost certainly fall into one of three buckets. Think of these as the legs of a stool—if one is weak, the whole thing topples over. We’re talking about the physical models you choose, the mesh you build, and frankly, the human operating the software.

1. Modeling Errors: Choosing the Right Physics for Your Problem

This is where experience really pays off. Software gives you a huge menu of turbulence models and physical equations, and picking the wrong one leads to garbage results. I remember a heat exchanger project from early in my career, about 15 years ago. My initial simulation using a standard k-epsilon model was almost 40% off the experimental data. It was completely useless.

The mistake? I’d failed to account for the strong swirl effects inside the tubes. Switching to a Reynolds Stress Model (RSM), which is more computationally expensive but captures anisotropy, brought the results to within 5% of reality. The software can’t tell you this; only an understanding of the underlying [Navier-Stokes equations and their practical limits] can.

2. Discretization Errors: Why Your Mesh Quality Is Non-Negotiable

This is a classic one. Your computer solves equations at discrete points in space, which we call a mesh. If your mesh is too coarse or has poorly shaped cells (high skewness), you’re not capturing the physics properly, especially near walls. It’s like trying to draw a circle with only 10 straight lines.

You absolutely must perform a mesh independence study. This means you keep refining the mesh until the results stop changing significantly. It’s tedious, but it’s the only way to be sure your answers aren’t just an artifact of your mesh. This whole process is a key part of the [core pre-processing stage of any CFD simulation] 📉. Don’t skip it.

3. Application & User Errors: The Human Factor in Simulation

Here’s the uncomfortable truth: the biggest source of error is often the user. A CFD code is a powerful tool, but it has no common sense. If you apply a wrong boundry condition—like setting an outlet pressure that makes no physical sense—it will happily solve it and give you a beautiful, completely wrong answer.

This is where the principle of “Garbage In, Garbage Out” is king. Knowing how to simplify geometry correctly, setting up realistic operating conditions, and interpreting the results with a critical eye are skills that seperate a novice from a professional. This is precisely why many companies opt for specialized [CFD analysis services]; they’re not just buying software time, they’re buying the critical judgment needed to produce trustworthy results. The question of how accurate is CFD often comes down to the person behind the keyboard.

The CFDSource Blueprint for Trustworthy Simulation: From Theory to Validated Results

Over the years, we’ve developed a rigorous process to ensure our simulations aren’t just academic exercises. It’s a blueprint built on one core idea: trust is earned, not assumed. It involves a constant cycle of questioning our own work, from the initial physics assumptions all the way to the final report. This isn’t just about running software; it’s a complete engineering workflow.

Verification & Validation (V&V): Our Cornerstone for Dependable Results

These two words get thrown around a lot, but they are absolutely not the same thing.

- Verification is the math check. It asks: “Are we solving the equations correctly?” This involves things like mesh convergence studies and checking code calculations. It’s an internal quality control step.

- Validation is the reality check. It asks: “Are we solving the correct equations for this problem?” This is where we compare our simulation results against real-world data.

You can have a perfectly verified simulation that is completely invalid because you chose the wrong physical model. We obsess over both.

The Power of Benchmarking: How We Validate Our Models Against Experimental Data

So, how do you validate? You need a benchmark—a source of truth. This could be data from a physical prototype, published academic papers, or wind tunnel test results. Without a benchmark, you’re just guessing.

Of course, building a physical test rig for everything isn’t practical, which is why knowing [when to use CFD versus physical prototyping] is a strategic decision in itself. When experimental data isn’t available, we often build simpler, benchmark cases based on well-understood problems to ensure our models and methods are sound before tackling the full, complex geometry.

The Art of Assumptions: How We Intelligently Simplify Without Compromising Reality

Every single CFD simulation is based on a set of assumptions. Anyone who tells you otherwise is selling you something. The skill is in knowing which assumptions are safe to make. Can we assume the flow is steady-state to save compute time? Is it okay to treat the fluid as incompressible?

These decisions separate an experienced engineer from a software operator. Making the wrong simplification can invalidate the entire simulation. It’s this deep understanding of the physics that underpins [our CFD consulting service] and ensures the results are not just colorful pictures, but reliable engineering data.

Accuracy in Practice: What’s “Good Enough” for Your Industry?

The acceptable margin of error changes drastically depending on the application. A 15% error in predicting airflow in an office building might be perfectly acceptable. That same error in predicting the lift on a wing would be catastrophic. The context is everything. Many [real-world applications of CFD] have different benchmarks for success.

Here’s a quick look at typical expectations:

| Industry Sector | Typical Goal | Acceptable Quantitative Error |

| Aerospace / Defense | Lift/Drag Prediction, Shockwave location | < 5% |

| Automotive | External Aerodynamics, Underhood Thermal | 5-10% |

| HVAC & Built Env. | Airflow Patterns, Comfort Metrics (PMV) | 10-20% |

| Electronics Cooling | Component Junction Temperatures | 5-10% of Temp Rise (ΔT) |

A Practical Checklist: 5 Questions to Ask Your CFD Provider to Guarantee Accuracy ✅

Before you commit to any CFD project, you should ask these questions. The quality of the answers will tell you everything you need to know about their process and expertise.

- What is your plan for Validation? How will you benchmark the results against reality?

- Can you show me the mesh independence study to prove the results aren’t mesh-dependent?

- Which turbulence model did you choose, and more importantly, why was it the right choice for this specific physics?

- What were the key assumptions and simplifications made, and how do they impact the final results?

- How did you determine the convergence criteria? Did you monitor just residuals, or also key physical quantities?

Beyond Accuracy: Partner with CFDSource for Actionable Engineering Insights

At the end of the day, a number on a page is useless. A result that is “98% accurate” means nothing if it doesn’t help you make a better decision. Our goal isn’t just to deliver an accurate number; it’s to deliver insight. To tell you why a design works, where it fails, and how to improve it. That’s the real value of simulation.

Ready to Transform Uncertainty into Design Confidence? Get a Project Feasibility Review

Understanding the nuances of simulation is key to leveraging it effectively. When you’re ready to move past the theory and see how simulation can impact your specific design challenges, the next step is a detailed review. This ensures that you have a clear picture of how accurate CFD can be for your unique application.