1. Beyond Static Simulation: Why a CFD-Based Digital Twin is Your Next Competitive Edge

Let’s be honest, for years, CFD has been a “what-if” tool. We run a simulation, analyze the results, make a design change, and run it again. It’s powerful, but it’s always been a snapshot in time. A digital twin changes the game entirely. It’s not a static picture; it’s a live, breathing model of your physical asset, continuously updated with real-world data.

This isn’t just another buzzword; it’s a fundamental shift in how we approach product lifecycle management and operational efficiency. It’s a core component of the next generation of engineering analysis, a topic we explore deeply in our guide to Advanced CFD: A Deep Dive into Modern Simulation Techniques. This is about moving from predicting performance to actively managing it in real-time.

2. What Exactly is a CFD-Based Digital Twin? A Practical Definition for Engineers

Forget the overly academic definitions. A CFD-based digital twin is essentially your most accurate CFD model supercharged with live data from IoT sensors. Think of it like this: your standard CFD model is a detailed architectural blueprint. The digital twin is that blueprint overlaid with live security camera feeds, temperature sensors, and stress gauges from the actual building. 🧐

It’s a living simulation that mirrors the asset’s current state, its history, and can then be used to predict its future. This fusion of the virtual and physical worlds allows you to test operational changes on the digital model before applying them to the real thing, preventing costly downtime or failures.

3. The CFDSource Blueprint: A 5-Stage Roadmap to Your Live Digital Twin

So, how do you actually build one of these? It’s not a simple software install; it’s an integrated engineering project. Based on our experience, we’ve broken the process down into a clear, manageable roadmap:

- Scoping & Feasibility: Defining the exact business problem you’re trying to solve and identifying the critical data points.

- High-Fidelity Model Development: Building and validating the core CFD simulation that acts as the physics-based anchor.

- Reduced-Order Model (ROM) Creation: The “magic” step that enables real-time calculations.

- Integration & Connectivity: Hooking up the model to live data streams from your physical asset.

- Deployment & Continuous Calibration: Going live and ensuring the twin remains accurate over its lifetime.

4. Stage 1: Scoping & Feasibility – Defining the Problem for Maximum ROI

After 15 years in this field, I can tell you one thing: the most expensive engineering mistake is perfectly solving the wrong problem. I once worked on a project for a massive industrial heat exchanger where the client was convinced they needed to optimize flow distribution. We spent weeks on it. It turned out the real issue was localized material degradation due to thermal cycling, something their sensors weren’t even tracking.

That’s why this first step is everything. It’s a deep dive to pinpoint the critical failure modes or optimization opportunities that will deliver a tangible return on investment. The real question you have to ask is not ‘can we build it?’ but ‘what critical business decision will it drive’. A thorough initial assessment, which is a core part of our CFD Analysis Services, can save you a fortune down the line.

5. Stage 2: The Foundation – High-Fidelity CFD Modeling & IoT Sensor Strategy

The heart of your digital twin is a robust, validated CFD model, likely built in a tool like Ansys Fluent or OpenFOAM. This isn’t just any simulation; it’s the physics-based anchor for the entire system. Building a CFD-based digital twin that you can trust starts with a high-fidelity model that has been rigorously validated against experimental or operational data.

Simultaneously, you need a smart sensor strategy. You don’t need to measure everything, everywhere. You need the right data from the right locations to feed and calibrate the model effectively. Be prepared, because these models generate enormous amounts of information, which brings its own challenges in strategies for handling terabyte-scale CFD datasets.

6. Stage 3: The “Real-Time” Challenge – Developing Reduced-Order Models (ROMs)

Here’s the million-dollar question: How do you get a CFD simulation—something that can take hours or days on an HPC cluster—to give you answers in seconds? The answer lies in Reduced-Order Models (ROMs). A ROM is essentially a highly intelligent, data-driven approximation of your full CFD model.

We use the full, high-fidelity model to generate a massive dataset covering a wide range of operating conditions. Then, we use machine learning techniques to train a ROM on this data. The result is a lightweight model that can predict the system’s behavior almost instantly with remarkable accuracy. They are incrediby powerful for real-time control loops and what-if scenarios. This approach blends physics with machine learning, a topic that closely relates to the concepts in The Rise of Physics-Informed Neural Networks and AI in CFD.

7. Stage 4: Integration & Connectivity – Connecting Your CFD Model to Live Data Streams

A perfect model that can’t talk to the real world is just a science project. This stage is all about the plumbing. 🔌 It involves setting up the data pipelines, APIs, and communication protocols to get sensor data from your physical asset (often via an IoT platform) into your digital twin, and potentially sending operational commands back out. This requires a skill set that bridges the gap between mechanical engineering, data science, and software development.

8. Stage 5: Deployment & Continuous Validation – Operating and Calibrating Your Twin

Getting your digital twin “live” is a huge milestone, but the job isn’t over. In fact, this is where the real value begins. Physical assets change—they wear down, operating environments shift, sensors can drift. Your digital twin must adapt. We call this “model drift,” and if you ignore it, your twin’s predictions will slowly diverge from reality until they become useless.

This is why continuous validation is non-negotiable. The system needs to constantly compare its own predictions against new, incoming sensor data. When the deviation exceeds a certain threshold, it should trigger a recalibration process. This is where you need a solid framework for quantifying the uncertainty in your predictions, so you always know the confidence level of your twin’s output. It ensures the tool remains a reliable decision-making asset for its entire operational life.

9. Choosing Your Tech Stack: Ansys, OpenFOAM, or a Hybrid Approach?

People often ask me, “Which software is best for this?” The answer is always: it depends entirely on your specific problem, budget, and in-house expertise. There’s no single “best” tool. Ansys offers a polished, integrated workbench with incredible support, which is fantastic for teams that need to move fast. OpenFOAM, on the other hand, is open-source, offering unparalleled flexibility for custom physics… if you have the deep expertise to wield it.

Often, the most powerful solution is a hybrid one. You might use a commercial tool for the core model development and then integrate open-source libraries for the real-time data handling and ROM deployment. Here’s a quick, no-nonsense breakdown:

| Factor | Ansys Fluent | OpenFOAM |

| Licensing Cost | High (Commercial) | Free (Open-Source) |

| Ease of Use | High (GUI-driven) | Low (Code-based) |

| Support | Excellent (Official) | Community-driven |

| Costomization | Moderate | Virtually limitless |

| Best For | Standard industry problems, fast deployment | R&D, unique physics, academic work |

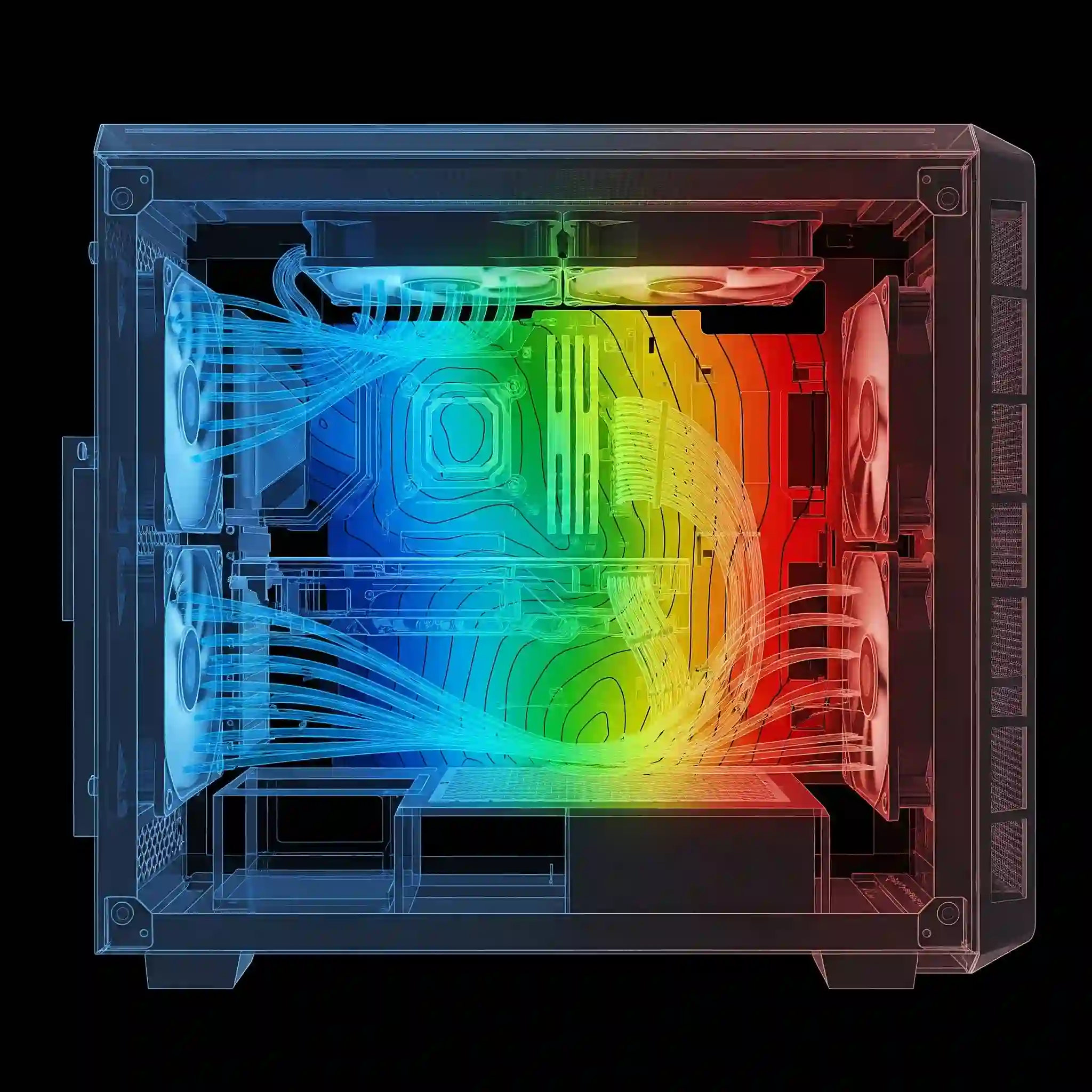

10. Case in Point: A Digital Twin for Optimizing Thermal Management in an EV Battery Pack

Theory is great, but let’s talk about a real project. We worked with an EV startup whose prototype battery pack was overheating during aggressive fast-charging cycles. Physically instrumenting every single cell with sensors was impossible. The solution? A digital twin. We started by leveraging high-performance computing for the initial CFD models to create an extremely detailed thermal model of the entire pack.

This full model was then used to train a ROM that could predict the temperature of any cell in the pack in real-time, based on just a few strategically placed physical sensors and the live charging data. The twin allowed them to test new coolant flow strategies virtually, leading to a revised control logic that reduced peak cell temperatures by 8°C and increased the battery’s projected lifespan. The project involved more than just CFD; it was about building a complete digital twin for the battery system. 🔋

11. Anticipating the Hurdles: 3 Common Pitfalls in Digital Twin Projects (and How We Solve Them)

Building one of these is complex, and things can go wrong. Trust me, we’ve seen these trip up even the smartest teams. Here are the big three:

- Garbage In, Gospel Out: Teams get so focused on the model that they neglect the quality of the sensor data feeding it. If your sensor data is noisy, infrequent, or just plain wrong, your twin is dead on arrival. We always insist on a data validation and cleanup stage before a single byte touches the model.

- The “Black Box” ROM: You build a mathematically perfect Reduced-Order Model, but the engineers who need to use it don’t understand how it works or why it makes certain predictions. This erodes trust. Our process always involves the end-users in the validation of the ROM, ensuring they trust its outputs.

- Organizational Silos: The CFD experts, the IT/data team, and the on-the-ground operations crew are not speaking the same language. A digital twin project forces these teams to collaborate closely. We often act as the bridge, translating between the different domains to ensure the project stays on track.

12. The CFDSource Advantage: More Than a Simulation, A Partnership in Innovation

Look, you can hire any number of firms to just “run a simulation.” But a digital twin is an integrated system, not a one-off analysis. It requires a partner who understands the full lifecycle, from the fundamental physics to the data integration and operational challenges.

This is where we’re different. We don’t just deliver a report; we embed with your team to ensure the solution is practical, trusted, and drives real value. Our goal is to make you self-sufficient in the long run. This philosophy is at the core of our CFD consulting service—we’re here to solve the problem, not just complete a task.

13. Key Takeaways: Your Checklist Before Starting a Digital Twin Project

Before you get started, here’s a quick sanity check. Ask yourself these questions:

- What specific, high-value business problem are we trying to solve? (e.g., “reduce unplanned downtime by 15%”)

- Do we have a strategy for acquiring clean, reliable sensor data?

- Is our high-fidelity model validated against real-world data?

- Do we have the multi-disciplinary team (CFD, Data, IT) to support this?

- What is our plan for long-term maintenance and recalibration of the twin?

14. Ready to Build Your Digital Twin? Explore the Possibilities

A digital twin is a significant undertaking, but the rewards in efficiency, reliability, and innovation are transformative. It represents a major leap forward from traditional simulation methods. If you’re exploring the feasibility of building a CFD-based digital twin for your application, the first step is a clear understanding of the scope and potential ROI. We hope this roadmap provides a valuable starting point for your journey.