The Engineer’s Dilemma: When to Simulate and When to Build?

It’s a question that lands on every engineer’s desk sooner or later. You’ve got a design, a deadline, and a budget. The pressure is on. Do you commit thousands of dollars and weeks of time to machine a physical prototype you can hold and test? Or do you dive into the virtual world of simulation? This isn’t just a technical choice; it’s a strategic one that can define a project’s success.

For anyone new to the simulation side of things, it’s worth understanding the fundamentals. We’ve put together the ultimate guide to CFD that covers the core concepts without the dense academic jargon. It sets the stage for everything we’ll discuss here.

Defining the Contenders: A Quick Look at Modern Engineering Tools

Before we pit them against each other, let’s be clear on what we’re talking about. These two approaches come from different philosophies but aim for the same goal: a product that works flawlessly in the real world.

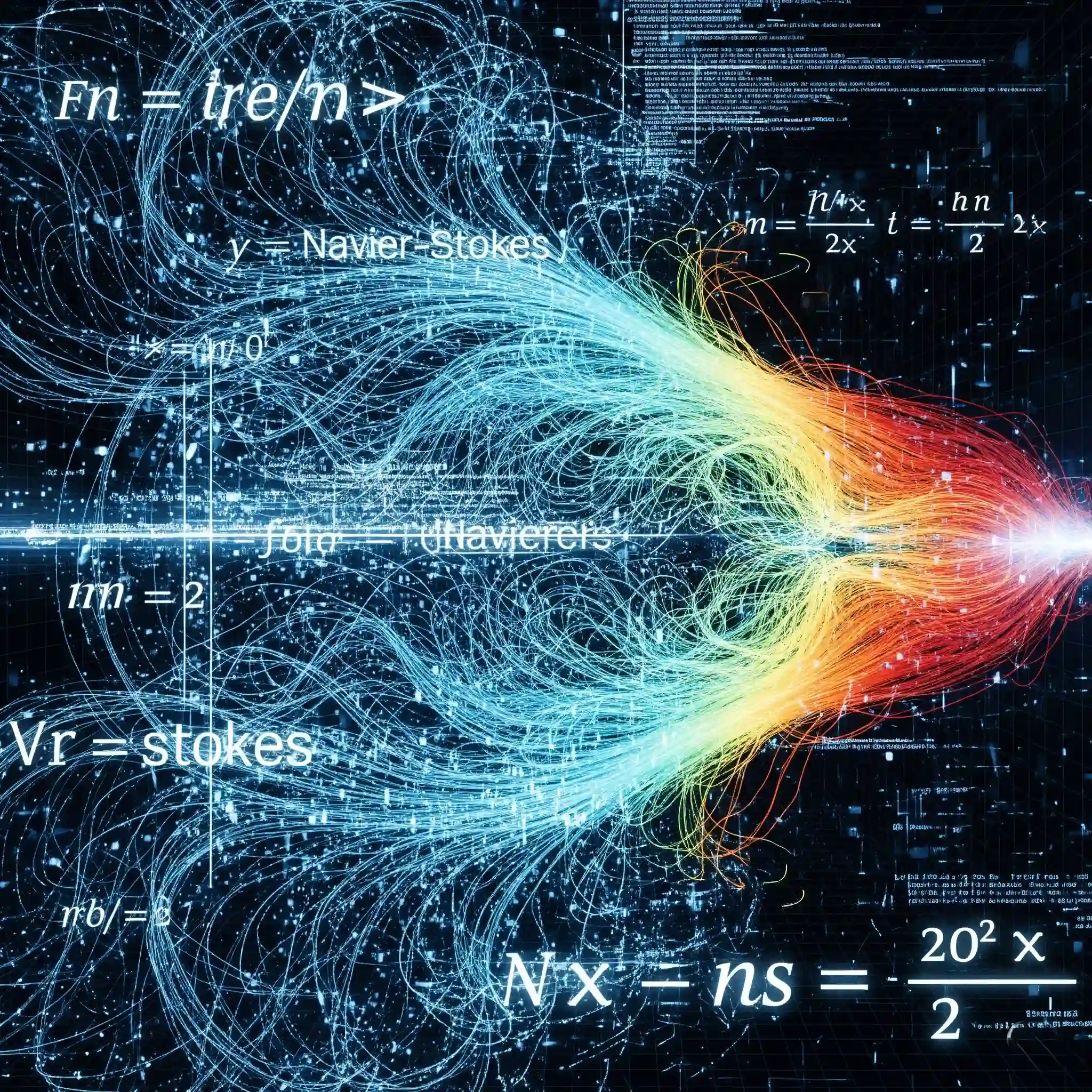

Let’s get one thing straight: CFD isn’t just about generating those impressive, rainbow-colored images for a presentation. At its heart, Computational Fluid Dynamics is a predictive tool. It uses numerical methods to solve the fundamental laws of fluid motion—yes, the infamous Navier-Stokes equations—to give us a virtual crystal ball 🔮.

It allows us to see the invisible. We can track the path of every air particle over a wing, map out the hotspots on a circuit board before it’s even fabbed, or see exactly where cavitation will start to eat away at a pump impeller. It’s an insight machine.

Nothing beats the feeling of holding a final part in your hands. A physical prototpye is tangible proof of your design. You can put it on a test rig, connect sensors, and get hard, empirical data. For decades, this was the only way, and it’s still considered the ultimate validation step.

But it has a dark side. I remember a project from early in my career, maybe 15 years ago. We were designing a high-pressure pump housing. The analysis looked okay, so we spent nearly $20,000 on a machined prototype. The moment we hit 80% of the target pressure on the test bench, a hairline crack appeared. All that time and money, gone. We had to go back to the drawing board, and the delay was brutal. That experience taught me the true cost of getting it wrong in the physical world.

The Ultimate Showdown: A Side-by-Side Comparison for Decision-Makers

Okay, enough theory. Let’s put these two head-to-head. When an R&D manager asks me for a recommendation, I usually sketch out a simple table like this to frame the discussion. It cuts through the noise and focuses on what truly matters for the business.

| Factor | CFD Simulation | Physical Prototyping |

| Initial Cost | Moderate (Software/Service) | High (Materials, Machining) |

| Iteration Cost | Low (Change parameter, re-run) | Very High (New part must be made) |

| Time per Iteration | Hours to Days | Days to Weeks |

| Data Depth | Extremely High (Full field data) | Low (Limited by sensor placement) |

| “Unseen” Issues | Excellent at finding them | Poor; can’t see internal flows |

| Final Validation | Requires validation | The validation itself |

Everyone focuses on the upfront cost, but the real killer is the cost of change. With a physical prototype, if you discover a design flaw—say, a flow separation causing unwanted vibration—you’re essentially back at square one. You have to redesign, remanufacture, and retest. Each loop costs significant time and money.

When you’re evaluating CFD vs physical prototyping on budget, think about it this way: CFD front-loads the investment. You pay for the expertise and computational time to explore ten, twenty, even fifty design variations virtually. This way, the first physical part you build is far more likely to be the last one you need. It’s a completely different economic model, and for complex systems, leveraging expert CFD Analysis Services is almost always more cost-effective than building a small mountain of failed prototypes.

In today’s market, speed is everything. Modifying a design in CFD can be as simple as changing a number in a parameter box and hitting “solve” again. You can test a new fillet radius or a different inlet angle overnight. Trying to do the same with a physical part involves new CAD drawings, sending them to the machine shop, waiting for the part, and scheduling new test rig time.

Weeks can shrink to days. This agility allows you to de-risk your design much earlier in the process. Understanding the core stages of a simulation shows you exactly where these time savings happen—primarily in the pre-processing and solving phases, where changes are digital and fast. It’s the difference between moving at the speed of thought and the speed of manufacturing.

Accuracy is the big one, isnt it? Anyone can make a pretty picture. The real question is, does it match reality? The truth is, a CFD simulation is only as good as the assumptions you feed it. Garbage in, garbage out. The physics is solid, but choosing the right turbulence model, creating a high-quality mesh, and defining proper boundary conditions is where the expertise comes in.

This is why we’re so transparent about the process. It’s not magic. It’s applied science that requires checks and balances. We’ve written an entire guide on understanding CFD accuracy and its potential errors because we believe clients should know what they’re getting. For critical projects, we often use a hybrid approach: CFD guides the design, and a final, single prototype is used to validate the simulation results, ensuring total confidence.

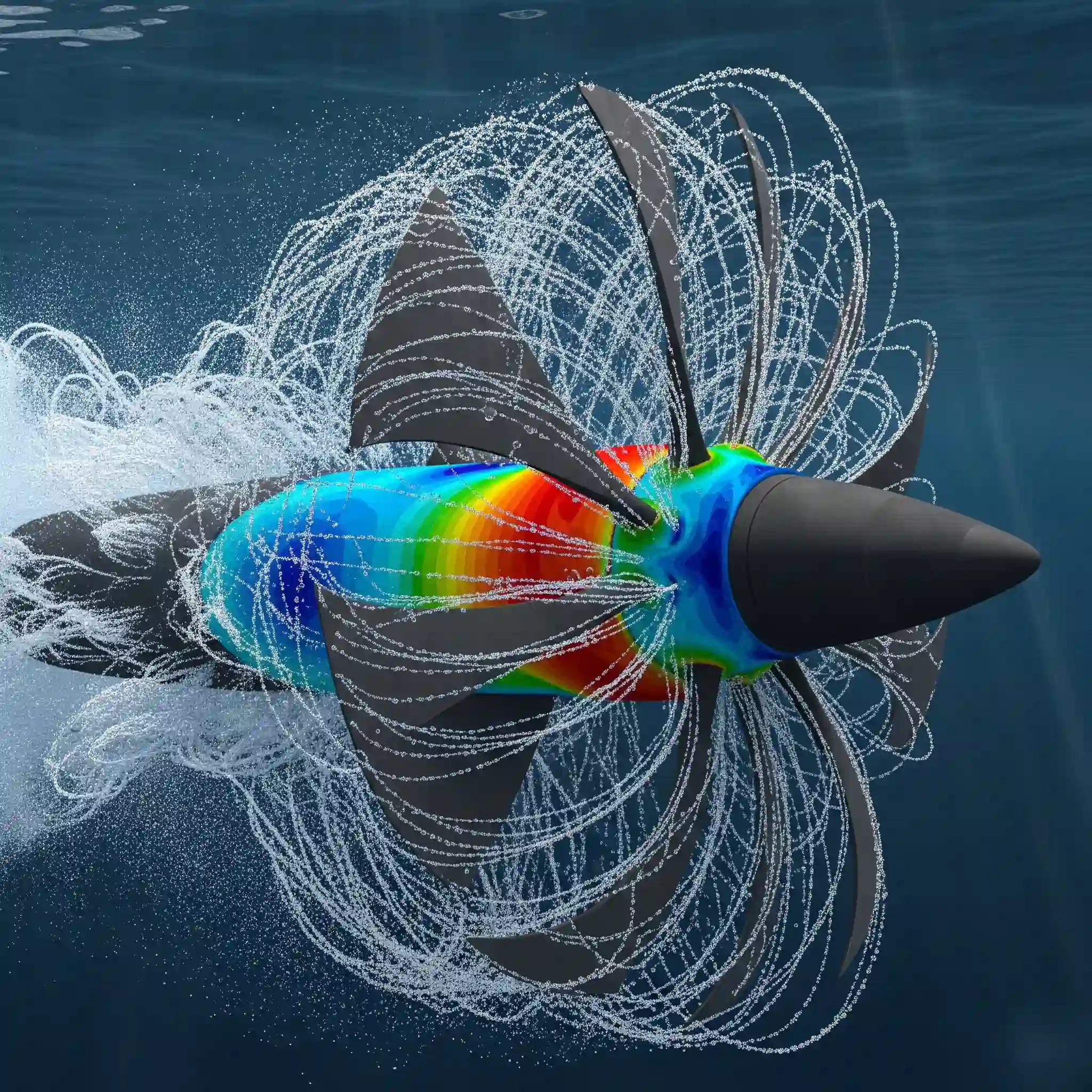

This is where simulation truly leaves physical testing in the dust. Imagine trying to measure the temperature at 500 different points inside a solid block of aluminum during operation. It’s impossible. With physical testing, you’re limited by where you can physically place a sensor. You get a handful of data points and have to interpolate the rest.

CFD gives you a complete, high-fidelity map of the entire system. You can see the temperature of every single point. You can plot streamlines to find recirculation zones that are robbing your pump of efficiency or see shockwaves forming on an airfoil that are invisible to the naked eye. It’s the difference between looking at a city through three keyholes versus seeing a full satellite image. 😉

Beyond “Vs.”: Why It’s a Partnership, Not a Battle

The smartest engineering teams I’ve worked with don’t see this as an either/or choice. They see it as a powerful workflow. The question isn’t “which one is better?” but “when do I use each one?” Thinking of them as competitors is a rookie mistake; they are complementary tools in a modern engineer’s toolkit.

Early-Stage Design: De-Risking Concepts with Rapid CFD Analysis

Early on, your design is fluid. You want to ask “what if?” a lot. What if I change the blade angle? What if I make this inlet 10% wider? This is where CFD shines. You can test a dozen concepts digitally in the time it would take to even get a quote for one physical prototype. You fail fast, fail cheap, and iterate toward a much stronger design before ever cutting a piece of metal.

Late-Stage Validation: Using Prototypes to Confirm Final CFD-Optimized Designs

By the time you commit to building a physical prototype, you should already be 95% confident it’s going to work. The prototype’s job is no longer discovery; its job is confirmation. It’s the final sign-off, the real-world proof that your CFD-driven design performs as expected. This dramatically reduces the risk of costly late-stage failures and redesign loops.

When is CFD the Undeniable Winner? Scenarios from Our Experience at CFDSource

Over the years, certain patterns emerge. While every project is unique, here are a few scenarios where leaning heavily on simulation first is almost always the right call:

- Internal Flow Systems: Anything where the critical action is happening inside the device (pumps, valves, manifolds).

- Thermal Management: Optimizing heat sinks, electronics cooling, or data center airflow.

- High-Cost Iterations: When the prototype is made of exotic materials or requires complex manufacturing.

- Concept Exploration: When you need to compare multiple, radically different designs quickly.

- The real-world applications of CFD are incredibly diverse, from medical devices to F1 cars, and in each case, it provides insights that are otherwise impossible to get.

We had a client with a new GPU design that was thermally throttling. Their prototype was overheating, but they didn’t know why. Our CFD analysis immediately revealed a small “dead zone” of stagnant air right over a critical memory module. A tiny change to a vent—something they would have never found by trial and error—solved the problem completely.

Another project involved reducing the drag and wind noise from a truck’s side mirror. The physical wind tunnel tests were expensive and time-consuming. We ran over 30 variations in the virtual wind tunnel, tweaking tiny curvatures and angles. The final proposed design, confirmed with a single physical test, reduced drag by 12% and cut wind noise significantly. Sometimes finding the right CFD freelancer with specific industry experience can make all the difference.

Your Final Checklist: Ask These 5 Questions Before Committing Your Budget

Before you sign that PO for a prototype or a simulation project, ask your team these simple questions. The answers will point you in the right direction.

- How many design iterations do we realistically expect? (If more than one, lean toward CFD).

- Is the most critical performance metric internal or external? (Internal heavily favors CFD).

- What is the cost of being wrong with our first physical prototype? (If high, de-risk with CFD).

- Do we need to understand why something is happening, or just if it happens? (Understanding ‘why’ requires CFD’s data depth).

- Where are we in the design cycle? (Early concept stage = CFD; final validation = prototype).

Making the right choice in the CFD vs physical prototyping debate is less about which tool is “better” and more about which tool is right for the job right now. Use the right tool for the right job, and your’e going to save time, money, and a whole lot of headaches.