There’s nothing worse than babysitting a simulation for hours, maybe even days, only to be greeted by that dreaded “floating point exception” error. We’ve all been there. It’s a frustrating roadblock that can halt an entire project. Often, the culprit is a lack of convergence. Before we dive into fixing it, if you’re new to this whole world, you might want to check out our foundational guide on What is CFD? to get the big picture. It’s a huge topic, but understanding what convergence in CFD is lies at the heart of getting reliable results.

Why Your CFD Simulation is Crashing: The Critical Role of Convergence

Think of your solver as a tireless worker trying to solve a massive puzzle—the flow of fluid in your domain. With each iteration, it makes a guess, checks how wrong that guess was (this error is the ‘residual’), and then makes a better guess. Convergence is simply the point where these guesses stop changing significantly. The solution becomes stable.

If it never reaches that stable point, it diverges. The errors compound, the numbers spiral out of control, and your simulation explodes mathematically. 💣 That’s when you get the crash. It’s the software’s way of saying, “I can’t find a stable physical answer with the instructions you gave me.”

Demystifying Convergence: What Does It Actually Mean in a Simulation?

Let’s make it simpler. Imagine you’re trying to guess a number between 1 and 100. Your first guess is 50. I say ‘higher’. You guess 75. ‘Lower’. You guess 63. ‘Higher’. Your adjustments get smaller and smaller until you’re bouncing between, say, 67 and 68. You’ve ‘converged’ on the answer. A CFD solver does the same thing, but for millions of equations at once for pressure, velocity, and temperature across your entire mesh.

But here’s the tricky part, and it’s a big one: just because the solver stopped changing its mind doesn’t mean it’s final answer is correct.

Convergence vs. Accuracy: A Common Misconception That Can Invalidate Your Engineering Results

This is the single biggest trap for beginners. Convergence means the math is stable. Accuracy means the stable math matches reality. You can have a perfectly converged solution that is completely, utterly wrong. It’s like using a broken scale that consistently tells you you weigh 10kg. The reading is stable (converged), but it’s not accurate.

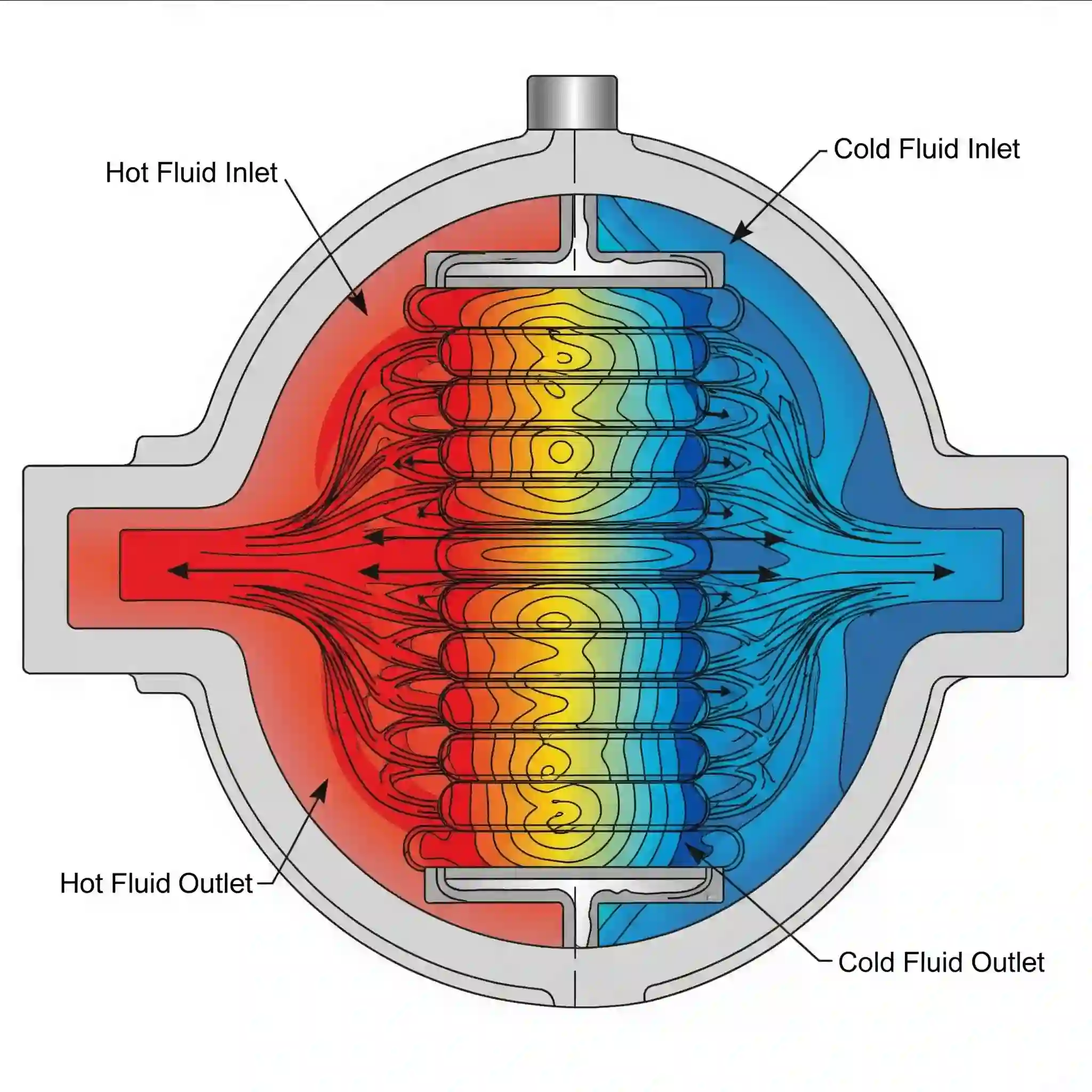

I remember early in my career, after years of doing this stuff, spending a week on a heat exchanger simulation. The residuals looked beautiful—flat lines, perfect convergence. But the final temperature was 20 degrees off the experimental data. Why? My choice of turbulence model was wrong for the flow regime. The simulation converged to a wrong answer. That lesson cost us time and taught me to always question the physics, not just the numbers. A clean geometry preparation for analysis can also make a world of difference here.

How to Monitor Convergence Like a Pro: Your Dashboard of Key Indicators

So, how do you keep an eye on this process? Don’t just hit ‘run’ and pray. You need a dashboard. Your CFD software gives you several ‘gauges’ to watch, and a good engineer monitors all of them, not just the flashiest one. Getting these right is as fundamental as selecting the correct boundary conditions.

Reading the Residuals Plot: Is Your Solution Stable, Oscillating, or Diverging?

This is your primary health monitor. It plots the ‘error’ for your equations (continuity, momentum, energy, etc.) at each iteration. Ideally, you want to see all these lines drop steadily and then flatten out at a very low value (typically below 1e-3, but it depends on the physics).

Here’s a quick cheat sheet:

- Good Convergence: Lines drop sharply and then plateau at a low level.

- Oscillating: Lines drop but then start wiggling up and down. This might be okay for unsteady phsyics, but it’s a warning sign in steady-state simulations.

- Diverging: The lines go UP. Abort mission! 🚀 Your solution is unstable and running away.

Beyond Residuals: Why Monitoring Physical Quantities (Drag, Pressure Drop) is Non-Negotiable

Relying only on residuals is a rookie mistake. The real question is: have the physical results you actually care about stopped changing? This is what separates a student project from an industrial-grade one. You need to set up monitors for key engineering values before you even start the simulation.

For example:

- Aerospace: Monitor Lift and Drag coefficients on an airfoil.

- HVAC: Monitor mass flow rate through a vent.

- Heat Transfer: Monitor the average temperature on a critical surface.

When the values on these monitors flatten out and become constant, even if your residuals are still wiggling a bit, you have reached a much more meaningful state of convergence. This is the kind of detailed analysis our Fluid Dynamics Consultant team focuses on to ensure the results aren’t just pretty pictures, but actionable engineering data that you can bet your product on.

The Ultimate Troubleshooting Guide: 5 Reasons Your Simulation Isn’t Converging (And How CFDSource Fixes Them)

Okay, so your residuals are all over the place. Before you throw your computer out the window, let’s work through the most common culprits. This is the diagnostic process we follow internally, and more often than not, the problem lies in one of these areas. Getting to the bottom of how to achieve convergence in CFD is a process of elimination.

#1 – The Mesh: Is Your Simulation’s Foundation Cracked?

I can’t stress this enough: a huge percentage of convergence problems start and end with the mesh. A poor quality mesh with highly skewed or distorted cells is like trying to build a skyscraper on a foundation of sand. The solver simply can’t handle the bad math these cells create.

Always check your mesh quality metrics before you run. Look for high skewness (>0.85 is often a red flag) and bad aspect ratios. Sometimes just a few bad cells can ruin the whole simulation. If you’re struggling with this, it’s worth reviewing the fundamentals of understanding CFD meshing concepts, as it’s truly a make-or-break step.

#2 – Solver Settings: Taming the Beast with Under-Relaxation Factors & Courant Numbers in Fluent/CFX

Your solver settings are the controls on your machine. Under-Relaxation Factors (URFs) in segregated solvers (like in Fluent) basically control how much of the “new” solution is applied at each iteration. If your solution is unstable, the first thing to try is reducing the URFs for pressure and momentum (e.g., from 0.7 to 0.5 for pressure, 0.3 to 0.2 for momentum). It will slow things down, but it makes the process more stable.

For coupled solvers (like in CFX), the Courant Number is a key parameter. A high Courant number means you are trying to push information through the mesh too quickly for the solver to keep up. Lowering it can often stabilize a diverging solution.

#3 – Physics & Boundary Conditions: The “Garbage In, Garbage Out” Principle

Your simulation can converge perfectly to a solution that is physically impossible. Did you accidentally set an outlet as an inlet? Is your fluid density correct? Is the problem inherently unsteady but you’re trying to solve it as steady-state? This is a sanity check. A solution that diverges violently from the start often has a fundamental setup error in the physics or boundary conditions. It’s the ultimate “garbage in, garbage out” scenario.

The CFDSource Convergence Checklist: Best Practices from Our Industrial Projects

Over the years, we’ve developed a mental checklist to avoid common pitfalls. Here are a few key points we always consider:

- Start Simple: Begin with a coarser mesh and a simpler physics model (e.g., laminar instead of turbulent). Once that converges, you can gradually add complexity.

- Initialize Wisely: A good initial guess can drastically improve convergence. Don’t just start from zero for all fields if you have a better idea of the flow.

- Check Your Units: A classic mistake. Are you working in mm or meters? Pascals or bar? It seems simple, but it catches everyone out at least once.

- Monitor Everywhere: Don’t just watch residuals. Set up monitors for forces, mass flow, and surface temperatures. These tell the real story.

- Save Your Work: Save case files at different iteration counts. If the solution diverges, you can go back to a previously stable point instead of starting from scratch.

What About Unsteady (Transient) Simulations? A Different Mindset for Convergence

For unsteady simulations, the game changes. You’re not looking for one final, steady answer. Instead, you need convergence within each time step. This means for every small jump forward in time, the solver iterates until the residuals drop below your criteria for that specific moment.

If it fails to converge in a time step, it’s often because your time step size is too large. The physics are changing faster than the solver can capture. Reducing the time step is the most common fix.

When Is “Good Enough” Actually Good Enough? Defining Your Convergence Criteria

There’s no magic number. For a quick design iteration, residuals of 1e-3 might be fine. For a final validation study intended for a research paper, you might need to push them to 1e-6. The real answer is: your simulation is converged enough when the key physical quantities you are measuring (like drag, or heat transfer coefficient) are no longer changing.

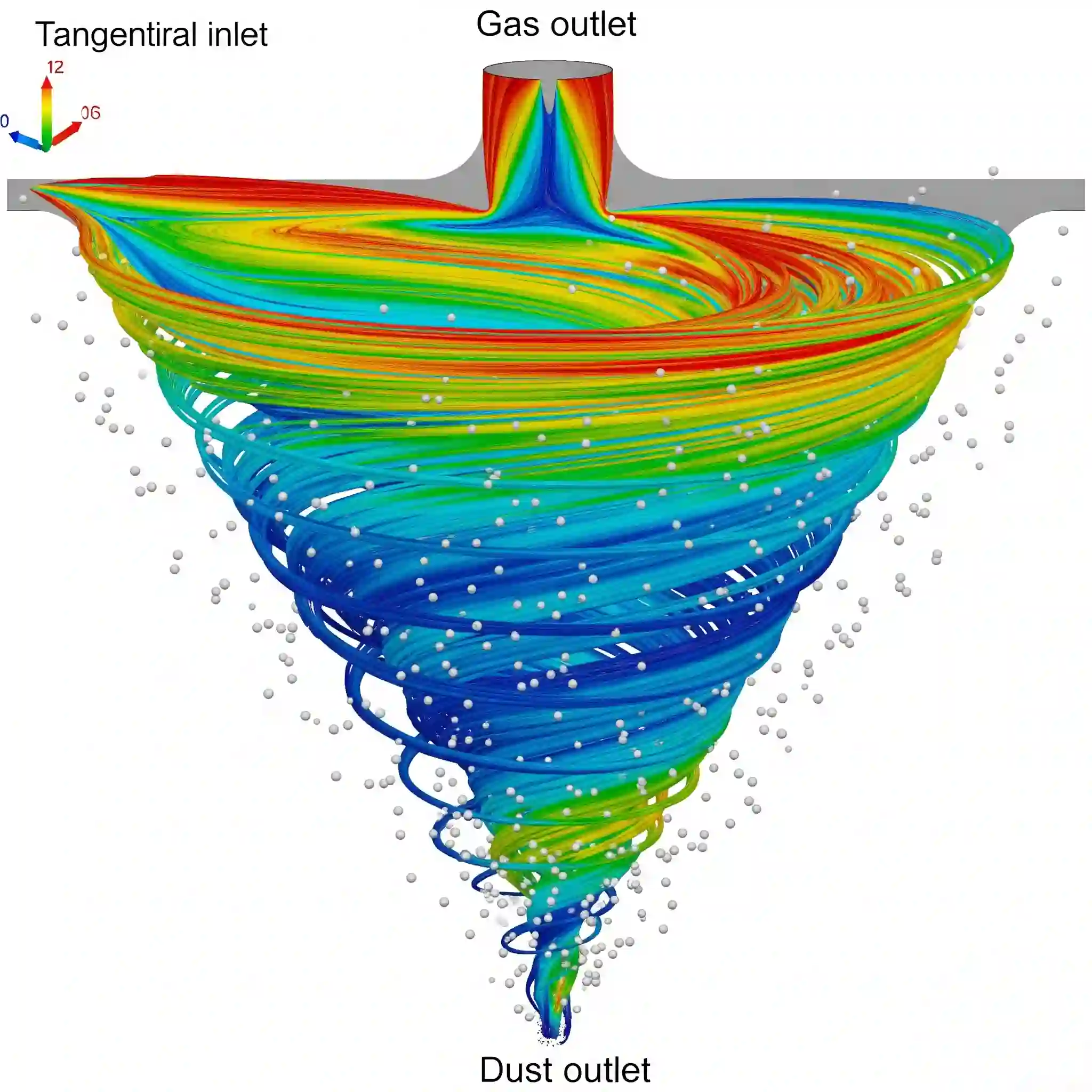

This is often confirmed with a mesh independence study, where you show that refining the mesh further doesn’t significantly change the final result. Once you have that, you can have high confidence in your data when you get to the stage of visualizing and interpreting your CFD results.

Conclusion: From Frustration to Fast, Reliable CFD Results

Convergence isn’t just a hurdle to overcome; it’s a window into the health and stability of your simulation. By understanding what it means, monitoring it correctly, and having a systematic approach to troubleshooting, you turn it from a source of frustration into a tool for building confidence.

Is Your Project Stalled by Stubborn Convergence Issues? Let CFDSource Experts Take Over

Sometimes, you don’t have time for the diagnostics. When a project deadline is looming and a simulation just won’t cooperate, an experienced hand can make all the difference. Complex physics like multiphase flow or combustion introduce unique stability challenges that require a specialist’s touch. If your problem is mission-critical, you can learn more about our CFD Consulting Services. Ultimately, our job is to provide you with accurate, actionable results, and that always begins with a robust understanding of how to monitor and achieve convergence in CFD.