Ever wondered why a bridge like the Tacoma Narrows could tear itself apart in a 40-mph wind, while a modern skyscraper barely sways in a hurricane? The answer isn’t just about steel and concrete; it’s about the invisible dance between a fluid (air) and a structure. That dance is called Fluid-Structure Interaction, or FSI. This isn’t just another textbook article. After spending 15 years wrestling with these complex problems, from tiny biomedical devices to massive industrial turbines, I’ve seen where simulations go right and where they fail spectacularly.

This guide is designed to cut through the academic jargon and give you a practical roadmap. We’ll explore the core concepts, why they matter, and how to approach them without getting lost. This is a key part of our broader series, and if you want the full picture, you can check out our deep dive into modern CFD techniques.

Understanding the Core Physics: One-Way vs. Two-Way FSI Explained

Before you can run a simulation, you need to know what you’re actually asking the computer to do. The biggest initial choice is between one-way and two-way coupling. Think of it like a conversation.

One-way FSI is a monologue. The fluid talks at the structure. Imagine wind pushing against a thick concrete dam. The wind applies a load, and the dam deforms slightly, but that tiny deformation is so insignificant it doesn’t change the wind’s path. The fluid’s influence is calculated, passed to the structural solver, and the story ends there. It’s faster, simpler, but only tells half the story.

Two-way FSI is a true dialogue. The fluid pushes the structure, the structure deforms, and that new shape immediately changes how the fluid flows. This new flow then creates a different force on the structure, causing it to deform again, and so on. It’s a constant feedback loop. This is the reality for things like flags flapping in the wind, aircraft wings vibrating, or blood pulsing through a flexible artery. Successful two-way FSI simulations capture this dynamic interplay, but they are much more computationally expensive.

| Aspect | One-Way FSI | Two-Way FSI |

| Data Coupling | Fluid → Structure (One Direction) | Fluid ↔ Structure (Bidirectional) |

| Computational Cost | Lower (Often hours) | Significantly Higher (Days or weeks) |

| When to Use | Rigid structures, small deformations (e.g., static wind load on a building) | Flexible structures, large deformations, vibration analysis (e.g., heart valves, wing flutter) |

| Common Mistake | Using it when deformations are large, leading to inaccurate results. | Using it for rigid problems, wasting massive amounts of time and resources. |

When is Two-Way FSI Non-Negotiable? Key Industrial Applications

So, when do you absolutely need to commit to the complexity of a two-way simulation? It’s when the structural deformation is large enough to significantly alter the flow field. Here are some real-world examples I’ve encountered where settling for one-way would be a critical mistake.

Aerospace & Defense: Flutter analysis on aircraft wings.

This is the classic, and frankly terrifying, example. Flutter is a violent, self-exciting vibration that can destroy an aircraft wing in seconds. It happens when aerodynamic forces and the wing’s natural vibrational modes couple in a destructive way. You simply cannot predict this with a one-way analysis because the very movement of the wing is what creates the unstable aerodynamic loads. It’s a problem that touches on some of the core challenges in supersonic flow simulation as well, where shockwaves can add another layer of complexity.

Biomedical Engineering: Blood flow through heart valves and stents. ⚕️

The human body is a masterclass in FSI. Consider an artificial heart valve. The flexible leaflets must open and close precisely with the pulsatile flow of blood. Their movement dictates the entire flow pattern, pressure drop, and potential for blood cell damage. Here, not only is the structure (leaflet) flexible, but the fluid (blood) is also complex. This often requires modeling complex Non-Newtonian fluids like blood in your CFD setup to get medically accurate results. A one-way simulation here wouldn’t just be wrong; it would be dangerously misleading.

Civil Engineering: Vortex-induced vibration on bridges and tall structures. 🌉

Let’s go back to the Tacoma Narrows Bridge. The phenomenon at play was vortex-induced vibration. As wind flows past a structure, it sheds vortices (swirling eddies) in a regular pattern. If the frequency of this shedding matches one of the structure’s natural frequencies, it can start to resonate, with the vibrations growing larger and larger. I remember studying this in university, and it’s still the classic example for a reason. The bridge’s twisting motion amplified the vortex shedding, which in turn amplified the twisting—a deadly feedback loop that only a two-way analysis can capture.

Energy Sector: Flow-induced vibration in heat exchanger tubes.

This is a less famous but incredibly common industrial problem. In power plants and chemical processors, you have bundles of tubes with fluid flowing around them to transfer heat. This flow can cause the tubes to vibrate. Over millions of cycles, this vibration leads to fretting wear and fatigue failure where the tubes are supported. We once worked on a case where a client’s heat exchanger failed prematurely, causing a costly shutdown. The initial analysis they did was one-way and missed the resonant vibration completely. By using a two-way FSI approach, we identified the problematic flow velocity and suggested a new baffle arrangement that solved the issue, saving them millions in the long run. Problems like these are why companies look for professional CFD analysis services that understand the physics deeply. It’s also an area where you might need to investigate and predicting cavitation damage if phase change is a risk.

Choosing Your Toolkit: A CFDSource Perspective on Ansys, COMSOL & OpenFOAM

Let’s talk tools. The software you use can make or break your FSI project, and there’s no single “best” one. It really depends on your project, budget, and how much you enjoy tinkering under the hood.

Ansys Workbench is the industry gorilla. Its biggest strength is the seamless integration between Fluent (for CFD) and Mechanical (for FEA) within the Workbench environment. The System Coupling module is powerful and makes setting up the FSI data transfer relatively straightforward. It’s a fantastic, robust choice for industrial work, but sometimes it can feel like a black box if you dont know what you’re doing.

COMSOL Multiphysics, as the name implies, was built from the ground up for these kinds of coupled problems. It’s brilliant when you have more than just fluids and structures interacting—maybe thermal effects or electromagnetism too. I find it’s a bit more transparent with its equation setup, which is great for researchers. The learning curve can feel steeper if you’re coming from a pure CFD background, though.

Then there’s OpenFOAM®. 🧠 It’s the free, open-source powerhouse. You get complete control over everything, which is amazing for developing custom solvers or highly specific physics. The downside? You’re the pilot, the mechanic, and the air traffic controller. The setup is complex and requires significant expertise and time. Choosing the right tool often comes down to deciding whether to build the capability in-house or partner with one of the specialized CFD analysis companies who already have the workflows and experience.

The 5-Step Blueprint for a Successful Two-Way FSI Simulation in Ansys Workbench

Alright, let’s get practical. If you’re using Ansys, here’s a simplified blueprint that will save you a world of headaches. This isn’t a click-by-click tutorial, but a strategic overview of the critical stages.

- Step 1: Geometry & Interface Definition:

This sounds basic, but 90% of FSI errors start here. Your fluid and solid domains must meet at a perfectly defined interface. Whether you use shared topology in SpaceClaim or just meticulous naming conventions, Ansys needs to know exactly which solid face talks to which fluid face. Get this wrong, and the data transfer will fail before you even start. - Step 2: The Art of Meshing for FSI:

You’re not just meshing one domain; you’re meshing two, and they have different needs. Your structural mesh needs to accurately capture stress concentrations, while your fluid mesh needs to resolve the boundary layer (hello, y+ values!). Good mesh quality is absolutly critical for the fluid domain that will be deforming. Use dynamic meshing methods like smoothing and remeshing in Fluent, and be prepared to spend a lot of time here. Garbage in, garbage out. - Step 3: Physics Setup:

This happens in parallel. In Fluent, you’ll set up your fluid properties, turbulence model, and boundary conditions. Critically, you’ll define the FSI interface as a “System Coupling” wall. Over in Mechanical, you’ll define material properties (structural steel, rubber, etc.), supports, and mark the same interface for FSI data transfer. - Step 4: Configuring the System Coupling:

This is the conductor of the orchestra. In the System Coupling module, you link the two solvers. You tell it: “Take the ‘Force’ from Fluent’s wall and apply it as a ‘Force’ on Mechanical’s surface. Then, take the ‘Displacement’ from Mechanical’s surface and use it to update the mesh in Fluent.” You’ll also set the data transfer controls here, which is key for convergence. - Step 5: Post-Processing & Interpreting Results:

Don’t just make a cool animation of something wobbling. Extract the data that matters. Plot the structural displacement over time to find the vibration frequency. Map the von Mises stress on the solid to see if it’s approaching failure. Look at the pressure contours on the fluid side to understand the forces at play. This is where you find your engineering answers.

“My FSI Simulation Won’t Converge!” – Troubleshooting the 3 Most Common Pitfalls

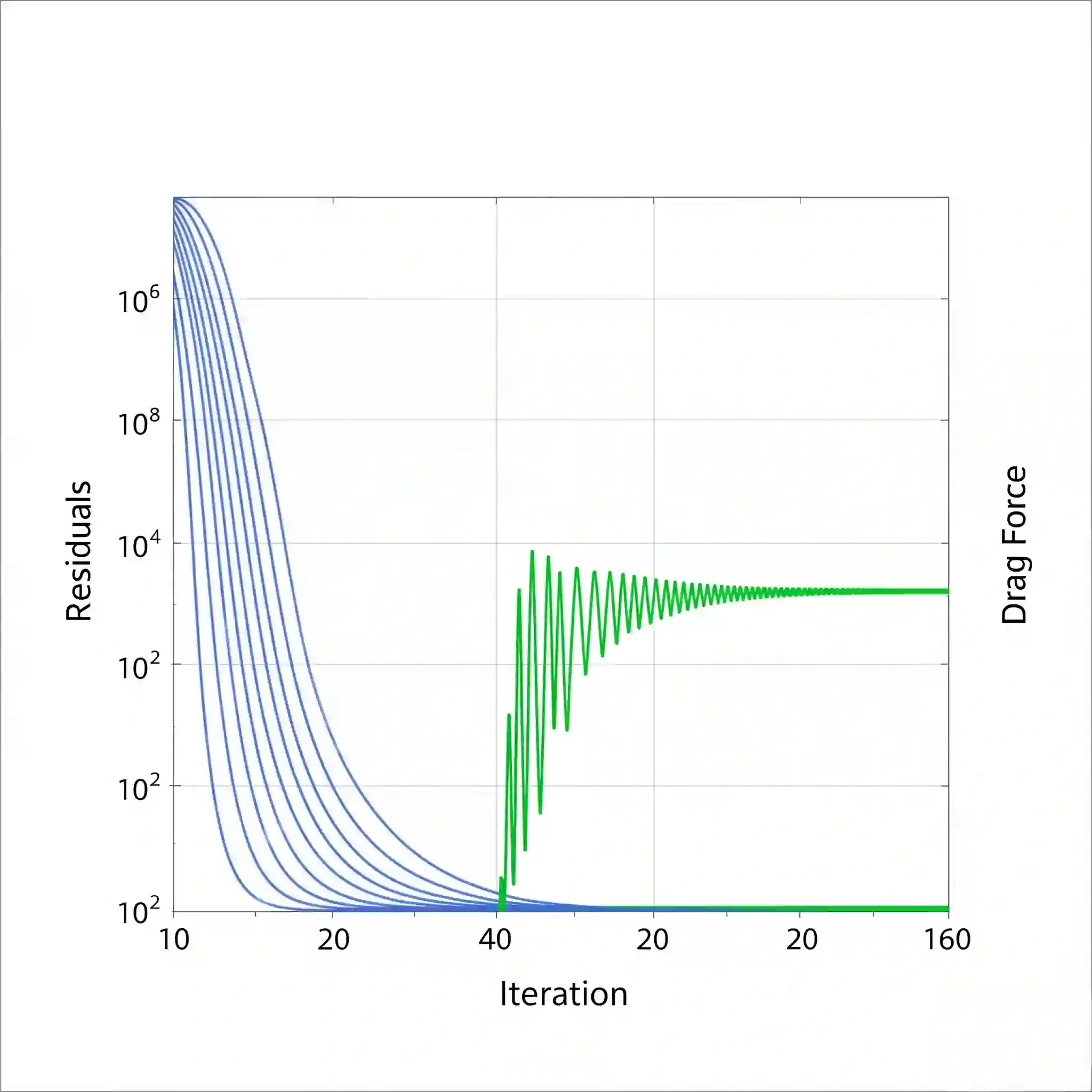

If you’ve run FSI simulations, you’ve seen the dreaded “solver error” message. It’s a right of passage. After countless late nights, I can tell you it almost always comes down to one of these three things.

- Pitfall 1: Negative Cell Volume. This is the classic dynamic mesh killer. The structure moves so much in a single time step that the fluid mesh gets tangled and folds over on itself. The fix? Reduce your time step size. Drastically. Or, get more aggressive with your remeshing settings so the mesh can rebuild itself before it breaks.

- Pitfall 2: Poor Data Transfer Settings. If the solution oscillates wildly and never settles, your data coupling is probably unstable. Go back to the System Coupling module and add some under-relaxation. This is like tapping the brakes on the data transfer, preventing the feedback loop from spiraling out of control. Start with a value of 0.75 and see if it helps.

- Pitfall 3: Unrealistic Time Step Size. Your time step has to be small enough to capture the physics. A good rule of thumb is to have at least 20-30 time steps per cycle of the highest frequency you expect to see. If you think your structure will vibrate at 100 Hz, your time step should be well below 1/(20*100) = 0.0005 seconds. Running with a time step that’s too large is just asking for a divergence.

From Simulation to Reality: Techniques for Validating Your FSI Model

A simulation is a model, not reality. Always treat your results with healthy skepticism until you’ve validated them. For FSI, this usually means comparing your simulation output against something tangible. This could be experimental data from a wind tunnel test, measurements from a real-world sensor, or even results from a published academic benchmark case. If you can get your simulation’s lift coefficient or vibration frequency to within 5-10% of a trusted source, you’re in a very good place.

Your Next Step in Solving Complex FSI Challenges

We’ve covered a lot of ground, from the core physics to the nitty-gritty of troubleshooting. The main takeaway should be this: FSI is a powerful tool, but it’s not magic. It demands a careful approach and a solid understanding of both the fluid dynamics and the structural mechanics at play. The vibrations and pressures we’ve been discussing are often a source of unwanted noise, a complex field in itself which we explore in our guide to aeroacoustics simulation.

Ultimately, paying attention to the details in the setup, understanding the physical feedback loops, and having a plan for validation is what separates a good two-way FSI analysis from a colorful but meaningless animation.