The Critical Choice in Multiphase Simulation: Why Your Model Selection Can Make or Break Your Project

Let’s get one thing straight. Choosing between multiphase models isn’t just an academic exercise. I’ve seen promising projects get bogged down for months because the wrong initial choice was made. You spend weeks setting up a simulation, burn through a massive computational budget, and end up with results that are either nonsense or simply won’t converge. It’s frustrating. This guide is built on years of running these simulations, learning the hard way so you don’t have to. We’re going to break down the Volume of Fluid (VOF) vs. Eulerian-Eulerian debate, not just by theory, but by practical application. This is a core topic within our broader exploration of advanced CFD simulation techniques.

Foundational Concepts: What’s Really Happening Under the Hood?

Before we compare them, it’s crucial to understand that VOF and Eulerian-Eulerian are designed to solve fundamentally different types of problems. They aren’t just two flavors of the same thing. One tracks a clean, sharp line between fluids, while the other looks at a blurry, mixed-up mess.

Understanding VOF: The Sharp Interface Tracking Approach for Free-Surface Flows

Think of VOF like pouring oil into a glass of water. You have a single, clear boundary—an interface—that you want to track as it moves and deforms. The VOF model is brilliant at this. It solves one set of momentum equations for the entire domain and uses a scalar variable (the volume fraction, α) to know whether a cell is full of fluid A, full of fluid B, or contains the interface. It’s main advantage is its ability to handle large interface deformations without losing the sharpness of the boundary. 📸

This makes it the go-to model for things like dam breaks, ship hydrodynamics, tank sloshing, or any scenario where you have two immiscible fluids with a well-defined interface.

Understanding Eulerian-Eulerian: The Interpenetrating Continua Approach for Dispersed Flows

Now, imagine shaking a can of soda and opening it, or a sandstorm in the desert. You don’t have one clear interface; you have millions of tiny bubbles or particles mixed within another fluid. The Eulerian model takes a very differant approach. It treats both phases as continuous fluids co-existing in the same space. It solves a separate set of conservation equations for each phase, which are linked by interaction terms (like drag).

This is the workhorse for industrial applications like fluidized bed reactors, bubble columns, pneumatic transport, and sedimentation processes. You’re not interested in the surface of a single bubble; you’re interested in the collective behavior of the bubbly flow.

Head-to-Head Comparison: VOF vs. Eulerian-Eulerian at a Glance

Alright, theory is great, but engineers need a cheat sheet. If you’re deciding between these two for a new project, this table is your starting point. It’s the quick-and-dirty breakdown I use when scoping a new challenge.

| Feature | Volume of Fluid (VOF) | Eulerian-Eulerian (E-E) |

| Interface Treatment | Sharp Interface Tracking (Explicit) | Interpenetrating Continua (Averaged) |

| Computational Cost | Moderate to High (requires fine mesh at interface) | High to Very High (solves two sets of equations) |

| Best For… | Free-surface flows, sloshing, jet breakup, filling | Dispersed flows, bubble columns, fluidized beds, sprays |

| Key Strength | Conserves mass perfectly, sharp interface resolution | Handles high volume fractions of dispersed phase |

| Main Weakness | Struggles with very small, dispersed droplets/bubbles | Smeared interface, heavily reliant on closure models (drag) |

Of course, some problems are more complex and don’t fit neatly in this table, especially when you’re dealing with things like [simulating non-Newtonian fluids] in a multiphase environment. In those cases, the decision requires a deeper look, which is where [professional CFD analysis companies] can often save you significant time.

Key Decision Factors: Accuracy, Computational Cost, and Physical Capabilities

Let’s dig a bit deeper into the “why” behind that table.

- Accuracy: With VOF, accuracy is all about your mesh. If your mesh isn’t fine enough to resolve the interface, you’ll get a smeared, inaccurate result. With the Eulerian model, accuracy hinges almost entirely on the quality of your sub-models—specifically, the drag, lift, and turbulence interaction models you choose. A bad drag model can give you results that are 50% off reality.

- Computational Cost: Don’t be fooled. While VOF solves only one set of equations, achieving a fine enough mesh at the interface can make it computationaly expensive. The Eulerian model is a beast from the start because it’s solving two full sets of transport equations. It almost always requires more computational power upfront.

- Physical Capabilities: This is a big one. Need to model phase change, like boiling or condensation? The Eulerian model has built-in frameworks for that. The VOF model can do it, but it often requires more complex user-defined functions (UDFs). The Eulerian model is built for interphase transfer (heat, mass, momentum), which is it’s core strength.

Application-Driven Selection: When to Use VOF in Your CFD Projects

So, when does VOF really shine? Think big interfaces. It’s the undisputed champion for any problem where you can clearly point and say “that’s the boundary between fluid A and fluid B.”

We’ve relied on it heavily for projects in:

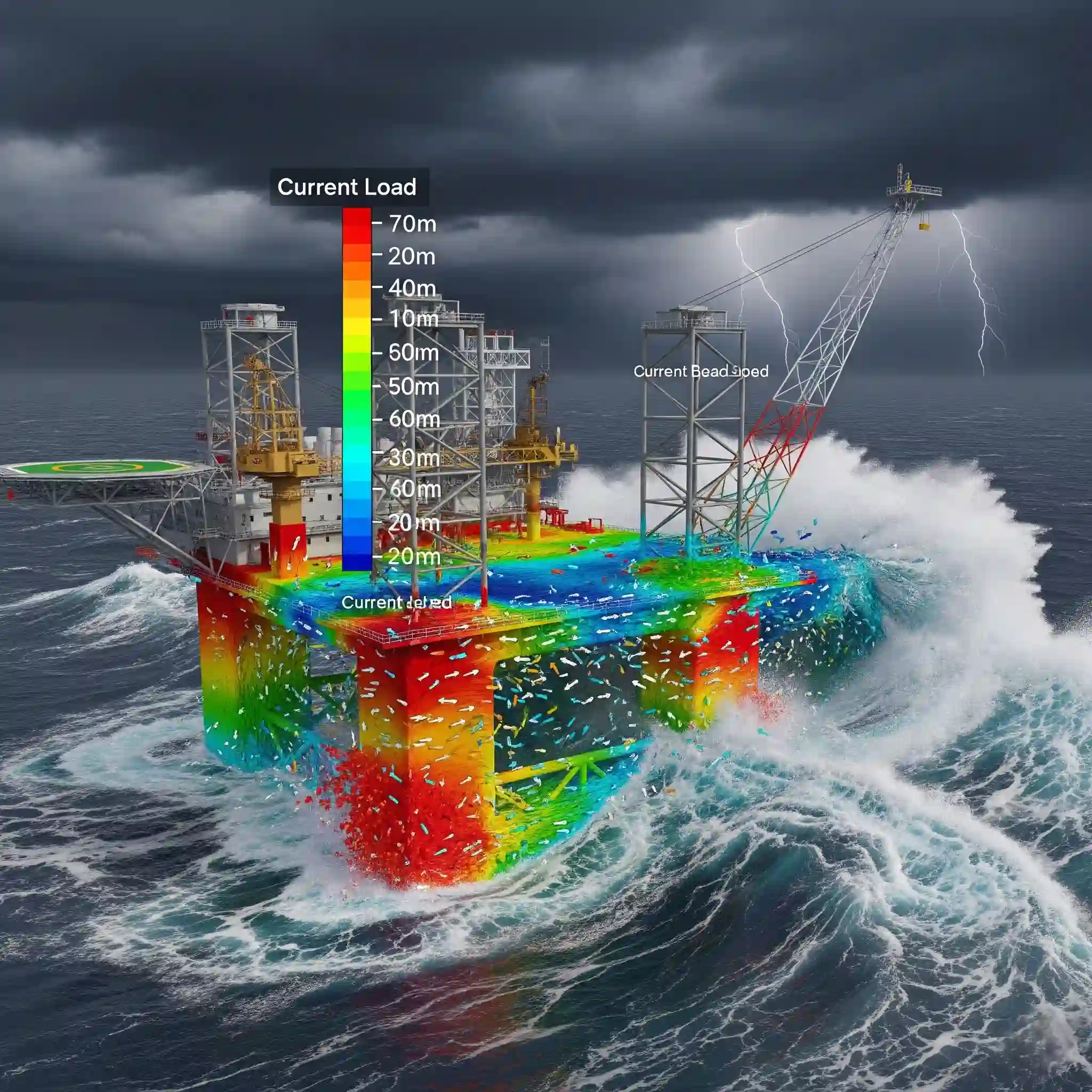

- Marine & Offshore: Simulating wave loading on offshore platforms or the hull resistance of a ship.

- Civil Engineering: Modeling spillway performance, dam breaks, and open-channel flows.

- Aerospace: Analyzing fuel sloshing inside a rocket’s propellant tank during maneuvers. This is critical for stability.

- Process & Manufacturing: Simulating mold filling, coating processes, and mixing in large vats.

If your primary goal is to predict the shape and position of a free surface, VOF is almost always your starting point.

Case Study Snapshot: Simulating Dam Breaks and Tank Sloshing with CFDSource

I remember a project for a chemical plant where they were concerned about a large storage tank failing. They needed to know the maximum force and height the resulting wave would exert on a critical downstream control building. This is a classic VOF problem—a violent, transient, free-surface flow. We built the model, and the simulation showed the wave would be significantly higher than their initial hand calculations predicted. The key challenge wasn’t just running the model, but ensuring our time-step was small enough to capture the peak impact force, which happens in a fraction of a second. The result? They were able to build a proper deflection barrier based on our data.

The Industrial Workhorse: When to Choose the Eulerian-Eulerian Model

Now for the messy stuff. The Eulerian model is for when your phases are intimately mixed and interacting everywhere. It’s less about a clean surface and more about a dispersed ‘soup’ of materials.

You’ll find the Eulerian model at the heart of major industrial processes:

- Chemical Engineering: This is its home turf. Fluidized bed reactors, bubble column reactors, and distillation trays are all modeled with this approach.

- Power Generation: Simulating boilers where water turns to steam, or coal gasification processes.

- Environmental Engineering: Modeling sedimentation tanks in wastewater treatment plants.

- Oil & Gas: Analyzing slurry transport or separation processes where you have oil, water, gas, and sand all mixed together. Problems like [predicting and mitigating cavitation] in pumps also fall into this complex multiphase world, even if the modeling approach can sometimes differ.

Our Experience: Modeling Fluidized Bed Reactors and Bubble Columns for the Process Industry

A few years back, a client in the pharmaceutical industry had a fluidized bed dryer that was producing an inconsistent product. Some of the powder was getting overheated while other parts remained damp. They suspected poor mixing. We built an Eulerian-Eulerian model of the dryer, treating the air as the primary phase and the powder particles as the secondary phase. The simulation quickly revealed “dead zones” where the air velocity was too low to properly fluidize the particles. Getting the drag model right for their specific non-spherical particles was the real trick. After we suggested a simple change to the inlet distributor plate design, they saw a dramatic improvment in product uniformity.

Common Pitfalls and Best Practices: Lessons Learned from 100+ Multiphase Projects

Running these simulations has taught us a few things, mostly by making mistakes first. Here are some of the biggest traps to avoid.

VOF Setup Checklist: Ensuring a Stable and Accurate Free-Surface Simulation in Fluent

VOF simulations are notorious for blowing up if you aren’t careful. Before you hit “calculate,” quickly check these: ✅

- Explicit Time Stepping: Are you using an explicit time formulation? If so, your time step MUST be small enough to satisfy the Courant number criteria (typically < 1). This is the #1 reason for divergence.

- Interface Meshing: Is your mesh sufficiently fine only where the interface will be? There’s no need for a super-fine mesh in the bulk fluid regions. Use mesh adaption.

- High-Resolution Schemes: Make sure your differencing scheme for the volume fraction is set to something sharp, like Geo-Reconstruct, to prevent artificial smearing of the interface.

Eulerian Model Challenges: Getting Drag and Turbulence Interaction Right

With the Eulerian model, the simulation will almost always run, but the results can be garbage if your physics are wrong. The biggest challenge is the “closure models” that define how the phases interact.

Your entire simulation’s accuracy rests on choosing the right interphase drag model (e.g., Gidaspow, Syamlal-O’Brien, Schiller-Naumann). The choice depends entirely on your flow regime (is it a dilute flow of particles or a dense, packed bed?). Secondly, how do the phases interact with turbulence? Does the presence of bubbles enhance or suppress the liquid’s turbulence? Getting this wrong is like navigating without a compass. These physical interactions become even more critical in extreme scenarios, echoing the [complexities found in supersonic and hypersonic simulations].

Making the Right Call: A Decision-Making Flowchart by CFDSource

Still on the fence? Ask yourself these questions in order.

- Is my goal to track a large, well-defined interface? (e.g., a wave, a filling process)

- Yes: Start with VOF.

- No: Go to question 2.

- Do I have one phase dispersed as particles, droplets, or bubbles inside another continuous phase? (e.g., bubbly flow, sand in water)

- Yes: Eulerian-Eulerian is your model.

- No: Your problem might be something else entirely, perhaps requiring a Lagrangian (DPM) approach or even a more specialized tool. This is particularly true for things like [the study of aeroacoustics], where the source of sound is often a complex fluid interaction.

Final Thoughts: It’s More Than Just a Model

At the end of the day, neither model is inherently “better.” They are different tools for different jobs. The most important skill is to look at your physical problem—really look at it—and identify the core behavior you need to capture. Is it the crisp movement of a surface, or the averaged, chaotic mixing of a dispersed system?

Choosing correctly from the start saves you time, money, and a whole lot of headaches. Ultimately, a successful Volume of Fluid vs. Eulerian multiphase analysis comes down to correctly identifying the fundamental nature of your flow before you even open the software.