1. The Critical Decision Point: Why Your Standard RANS Simulation Might Be Failing You

So, you’ve hit a wall. Your RANS simulation converges beautifully, the residuals look great, but the results just don’t match your experimental data. Or worse, the physics of the problem—the chaotic, swirling, unsteady stuff—is completely absent from your results. This is a common and frustrating point in any serious simulation work, a sign that you’re pushing past the limits of standard tools and into the realm of Advanced CFD techniques.

This isn’t just about tweaking your k-epsilon model anymore. It’s about fundamentally changing how you ask the software to look at turbulence. This guide is my attempt to lay out a clear thought process for knowing when to move from RANS to more advanced models like LES/DES, based on problems I’ve personally wrestled with in the field.

2. RANS: The Industry Workhorse – Understanding Its Power and Fundamental Limitations

Let’s be clear: RANS (Reynolds-Averaged Navier-Stokes) is the undisputed workhorse of industrial CFD for a reason. It’s fast, relatively robust, and for a huge range of problems, it’s perfectly adequate. After 15 years in this game, I can tell you that probably 80% of the industrial problems that come across our desks at CFDSource can be, and should be, solved with a well-posed RANS model.

The “magic” behind RANS is time-averaging. It essentially smooths out all the chaotic, transient fluctuations of turbulence and gives you a steady-state or mean-averaged result. I remember a project modeling flow around a building complex to assess pedestrian wind comfort. RANS gave us a great map of average wind speeds. But when the client asked about the intensity of wind gusts that could knock someone over, RANS was silent. It had averaged those critical, transient events into oblivion.

2.1. Where RANS Excels: Ideal Scenarios for Time-Averaged Models

Before we abandon it, know where RANS shines. You should stick with it for:

- Fully-developed turbulent flows in pipes or channels.

- External aerodynamics on streamlined bodies like airfoils at low angles of attack.

- Initial design iterations where you need quick comparative results, not absolute precision.

- Many heat transfer problems where the bulk flow behavior dictates the thermal performance.

2.2. The Achilles’ Heel of RANS: Time-Averaging and Its Impact on Transient Phenomena

The core limitation is right in the name: Averaged. RANS models don’t resolve turbulent eddies; they model their effect on the mean flow. Its the fundamental assumption that fails when the transient, large-scale turbulent structures are the very thing you need to understand. Think of it like this: RANS can tell you the average water level in a river, but it can’t describe the individual waves and whirlpools on the surface.

3. 5 Telltale Signs You Need to Upgrade from RANS

You’re likely reading this because you suspect your problem has those “waves and whirlpools.” Here are the dead giveaways that your RANS model is out of its depth:

- Massive Flow Seperation & Reattachment: If you have flow over a bluff body (like a truck or a building) or through a sharp bend where the flow detaches and creates a large, unsteady wake, RANS will often get the size and behavior of that wake wrong. Getting this right often requires expert CFD analysis services because the mesh setup is non-trivial.

- Vortex Shedding & Aeroacoustics: That classic von Kármán vortex street behind a cylinder? RANS will typically show a symmetric, steady wake. It completely misses the periodic shedding that is often the source of vibration and noise. This is critical if you’re trying to start [predicting flow-induced noise]. 🤔

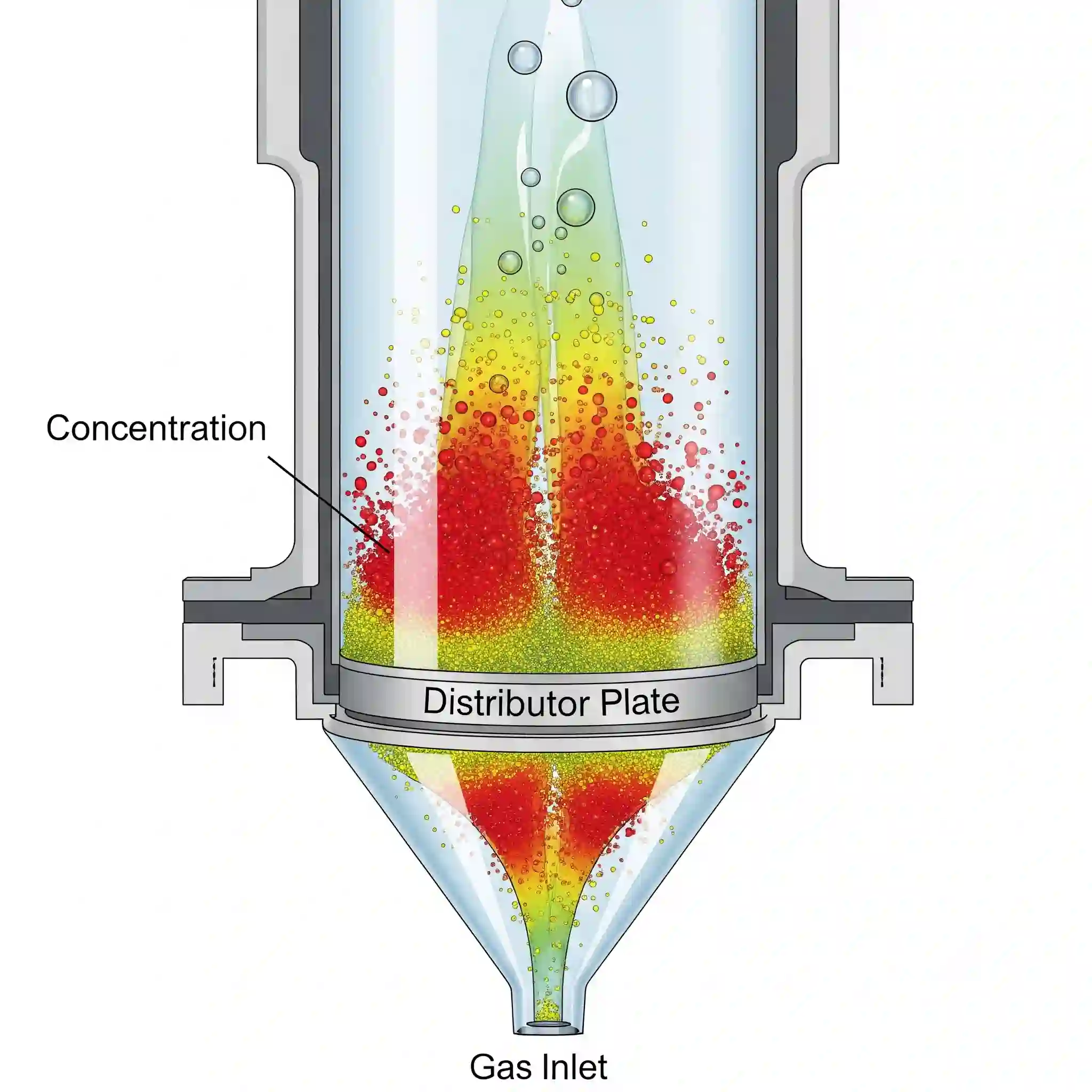

- Highly Unsteady Turbulent Mixing: Imagine injecting a cold fluid stream into a hot one at a T-junction. RANS will give you a smooth, smeared-out temperature field. In reality, large, energy-containing eddies cause significant temperature fluctuations (thermal striping) that can lead to thermal fatigue. LES/DES can capture this.

- Combustion Instabilities: In combustors, the interaction between acoustics, vortex shedding, and heat release can create destructive instabilities. RANS cannot predict these inherently transient, coupled phenomena.

- Need for Accurate Drag/Lift Fluctuation Prediction: If you need to know the fluctuating forces on a structure—like wind gusts on a bridge or the forces on a turbine blade—RANS is the wrong tool. It only gives you the mean force.

4. Beyond Averaging: A Practical Introduction to LES and DES

Okay, so RANS is out. Your next step is into the world of scale-resolving simulations. Instead of modeling all turbulence, these methods attempt to directly resolve the large, energy-carrying eddies and only model the smallest, most universal ones. This is a huge leap in fidelity. ⚙️

It fundamentally changes the meshing and solver requirements. This isn’t just about clicking a different button in the software; it’s a new simulation philosophy. Sometimes, the physics get even more complex, like when you’re [simulating cavitation in pumps], where unsteady vortices can trigger phase change.

4.1. Large Eddy Simulation (LES): Capturing the Energy-Containing Eddies

LES is the gold standard for turbulence resolution. The goal here is to create a mesh so fine, and a time-step so small, that you directly solve for the motion of all but the tiniest turbulent eddies. The computational cost is, frankly, enormous. You’re resolving a huge range of scales in both space and time.

This makes pure LES impractical for many high-Reynolds number industrial flows, especially those with attached boundary layers. It remains a powerful tool primarily for academic research and very specific industrial problems where absolute accuracy in a limited region is paramount.

4.2. Detached Eddy Simulation (DES): A Hybrid Approach for Industrial-Scale Problems

This is where things get really interesting for industrial applications. DES is a clever hybrid. It uses a RANS model in the regions where it’s good at—the thin, computationally expensive boundary layers attached to walls. But once the flow separates and large, unsteady eddies form, the model smoothly switches to an LES-like approach to resolve them directly.

It’s the pragmatic compromise. You get much of the accuracy of LES in the critical regions of separated flow, without the astronomical cost of resolving the entire boundary layer. We used this on an automotive project to analyze the wake behind a side-view mirror. RANS gave us a blurry, inaccurate wake structure, while DES perfectly captured the large-scale vortices responsible for wind noise, giving the design team actionable data.

5. The CFDSource Decision Matrix: Choosing Between RANS, LES, and DES

I find that engineers love a good table. It cuts through the noise. So, here’s a simplified matrix I use when discussing options with clients. There’s nuance to every project, but this is a solid starting point.

| Criteria | RANS (e.g., k-ω SST) | DES (e.g., IDDES) | LES (e.g., WALE) |

| Computational Cost | Low (Hours) | High (Days-Weeks) | Very High (Weeks-Months) |

| Mesh Requirement | Anisotropic, y+ sensitive | Hybrid: Anisotropic near-wall, isotropic in LES region | Isotropic, very fine everywhere |

| Turnaround Time | Fast | Slow | Extremely Slow |

| Accuracy (Unsteady) | Poor to Fair | Good to Excellent | Excellent (Gold Standard) |

| Typical Use Case | Initial design, steady aerodynamics, pipe flow | External aero (cars, planes), massive separation | Aeroacoustics, fundamental research, combustion |

6. The “Price of Precision”: A Realistic Look at the Computational Costs

Don’t underestimate the jump in resources needed. It’s not a 2x or 3x increase; it’s often a 100x or even 1000x increase in computational effort. A RANS simulation that runs overnight on your workstation might take two weeks on a high-performance computing (HPC) cluster when run with a DES model. 📈

This cost is a major factor, and it’s why our CFD Services often involve an initial RANS study to identify if and where a high-fidelity simulation is justified. You need to be sure the question you’re asking actually requires this level of precision.

7. From Theory to Terminal: Key Setup Changes When Migrating to LES/DES

Switching the turbulence model is just the first click. The real work is in rethinking your entire simulation setup. It’s a completely different mindset.

7.1. Your Meshing Strategy Must Evolve: Why y+ is Just the Beginning

With RANS, you’re obsessed with y+ and getting those prism layers right. That’s still important for the RANS part of a DES model. But for the LES regions, your focus shifts. You now need near-isotropic (cube-like) cells in the flow-field to avoid numerically damping the very eddies you want to capture. This is a very different meshing philosophy than what’s needed for, say, [practical FSI simulations] where the mesh quality has to survive significant deformation.

7.2. Solver Settings: Time-Step Selection and Numerical Schemes

Forget about steady-state solvers. LES/DES are inherently transient. Your time-step must be small enough to resolve the evolution of the large eddies. We’re talking Courant numbers typically less than 1. You also need to switch from robust (but diffusive) second-order upwind schemes to less-dissipative schemes like Bounded Central Differencing. Using the wrong scheme can kill your turbulence before it even forms.

8. CFDSource Case Study: Predicting Unsteady Wake Behind a Cylinder

A classic test case is flow past a cylinder. A RANS model will predict a steady, symmetric wake that is physically incorrect. We ran this exact comparison for a client worried about cable vibration.

- RANS Result: Showed a constant, non-zero drag coefficient and a zero lift coefficient. Boring.

- DES Result: Immediately captured the famous von Kármán vortex street. The lift coefficient plot showed a clear, periodic oscillation at the correct Strouhal number, allowing us to predict the frequency of vortex-induced vibration. This is the kind of insight that is simply impossible with RANS. The same physics governs much more complex scenarios, like [analyzing supersonic flows] where shock-vortex interactions are everything.

9. Common Pitfalls: 3 Mistakes Engineers Make When Adopting LES/DES (And How We Avoid Them at CFDSource)

I’ve seen these simulations go wrong in many ways. Here are the top three tripwires:

- Using a “RANS mesh”: Simply refining a RANS mesh is not enough. Without properly resolved isotropic cells in the region of interest, you’re just wasting CPU cycles.

- Not running long enough: You need to run the simulation long enough for the initial transients to wash out and then continue running to gather stable statistics. Cutting it short gives you beautiful but meaningless pictures.

- Incorrect boundry conditions: Using a simple velocity-inlet can suppress the natural turbulence needed for the simulation to develop correctly. You often need to use a synthetic turbulence generator. It’s a subtle but critical detail.

10. Is High-Fidelity Simulation Your Next Step? Let’s Find Out.

So, the decision isn’t just about accuracy; it’s a careful balance of physics, cost, and time. RANS will always be the first tool you reach for. But when your problem is dominated by transient, large-scale turbulent structures—the kind that cause vibration, noise, or unsteady thermal loads—you have to upgrade your toolkit. It’s not just for exotic problems either; even some complex [simulations of non-newtonian fluids] can benefit from resolving transient structures.

Hopefully, this engineer’s guide on moving from RANS to LES/DES gives you a clearer framework. If these challenges and decision points sound like what you’re facing on your project, it’s a strong sign that a deeper conversation about your simulation strategy is needed.