Simulation Shouldn’t Be a Bottleneck.

That’s it. That’s the core idea behind CFDSource.

My name is Aris Thorne. Before I started this company, I was a design engineer. I wasn’t the CFD specialist; I was the guy waiting for the specialist to finish his analysis so I could get on with my job.

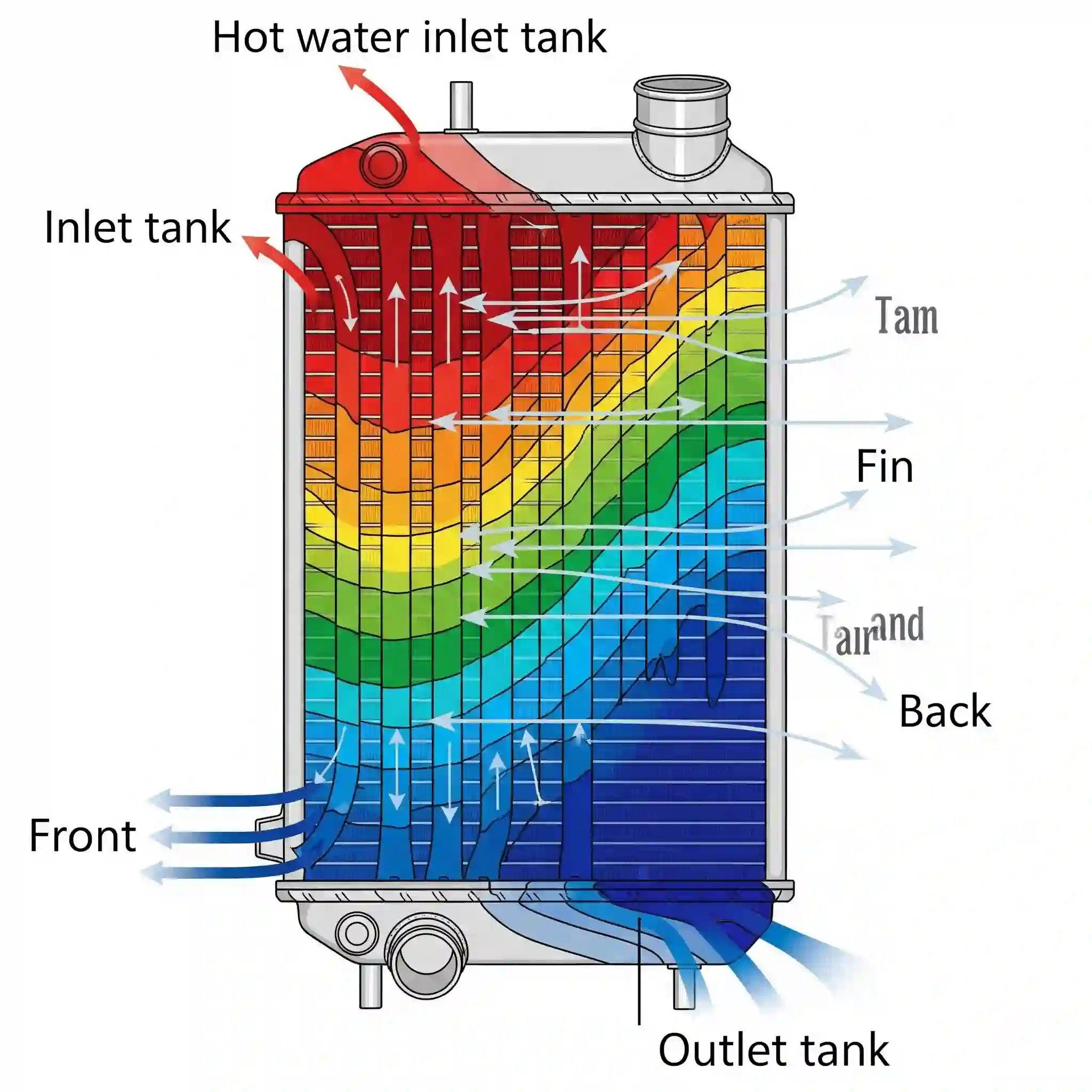

I once waited three weeks for a thermal analysis on a simple heat sink for a power electronics module. The project was on hold. When the report finally came back, it had a beautiful, rainbow-colored contour plot, a few dozen pages of data, and zero actionable advice. It told me what was happening, but not why, or what to do next. It was a bottleneck.

We started CFDSource to fix that problem. We’re a small, deliberately focused team. We don’t see CFD as a final validation step; we see it as a tool for conversation during the design process. We’re here to help you figure things out.

How We Think (Because “Philosophy” Sounds Too Grand)

We don’t have framed mission statements on the wall. We just have a few simple rules we operate by.

1. We tell you the truth, even if it’s complicated.

Sometimes, simulation results are messy. They might show that an early design assumption was wrong. We won’t hide that. Our job is to present the physics as they are and work with you to find a path forward. We’d rather have a difficult conversation early than let a flawed design move toward production.

2. We act like we’re on your payroll.

This means we adopt your deadlines and your sense of urgency. If we see something in the simulation at 7 PM that could impact your morning meeting, you’ll get a call. We integrate with your team through Slack, email, or whatever works for you. We’re not a disconnected vendor you have to chase for updates.

3. We use the right tool for the job.

Anyone can run a simulation with the most complex turbulence model and let it cook on a server for a week. It takes an expert to know when a simpler, faster model will give you 95% of the answer in a fraction of the time. We are pragmatic. Our goal is to get you reliable answers that fit your timeline and budget, not to write an academic paper.

The Team

Aris Thorne, PhD – Founder

- Background: Got my PhD at Purdue, spent some time in Germany at RWTH Aachen doing a post-doc. Over the last 17 years, I’ve been on both sides of the fence—design and analysis—mostly in the aerospace industry.

I still get my hands dirty on nearly every project. I’m the one who will be on the initial discovery call, and I’m probably the one who will call you mid-project to talk through an unexpected result. I love the “aha!” moment when a simulation reveals a simple solution to a problem everyone thought was incredibly complex.

Maria Valerio, MS – Simulation Engineer

- Background: Master’s from the University of Michigan. Spent my early career deep in the world of industrial pumps and turbo-machinery before getting into electronics cooling.

I’m the details person. I genuinely enjoy spending a full day just on mesh refinement and quality checks, because I know that’s where most errors hide. While Aris is often focused on the big-picture physics, I’m making sure the numerical foundation is rock-solid. If a result seems strange, I’m the one who will dig through the data to find out exactly why.

What We Actually Do: The Story of a Single Simulation

It’s easy to talk about partnership and collaboration. It’s harder to show what it means. So let me walk you through what a typical engagement looks like, beyond the buzzwords.

A few months ago, a client in the medical device space came to us. They had a handheld diagnostic tool that was failing its thermal certification. The engineers were frustrated; they had already tried a bigger heat sink and a more powerful fan, but the core processor was still overheating during prolonged use. They were running out of time and ideas.

Our first call wasn’t about the CAD file. It was about the context. We asked: “Who uses this device? For how long? In what environment? What happens when it overheats—does it shut down, or just slow down?” Understanding the real-world problem is always step one.

Then, we dove in. Maria ran the initial baseline simulation on their existing design. As expected, it confirmed the overheating. But it also showed something the team hadn’t seen: the fan, while powerful, was creating a large recirculation zone of hot air right next to the processor’s intake. The fan was essentially choking on its own exhaust.

We didn’t write a report. I called the lead engineer directly and shared my screen. We looked at the streamline plots together. It was an immediate “aha” moment for him.

From there, it became a rapid-fire collaboration. “What if we add a small baffle here?” he asked. We tweaked the geometry, ran a quick simulation overnight. The recirculation was reduced, but not eliminated. “Okay, what if we also move this capacitor that’s blocking the main airflow path?” Another tweak, another run.

The final solution wasn’t a bigger fan or a more expensive heat sink. It was a simple, 3D-printed plastic baffle, costing less than a dollar, and relocating one component on the PCB. The new simulation showed the core temperature dropped by 12°C, well within the safe operating limits.

That, to us, is the essence of what we do. It’s not about delivering a single, perfect simulation. It’s about being on a journey of discovery with you, using simulation as a flashlight to find the simple, elegant solution hidden inside a complex problem. We don’t just deliver answers; we find them with you.

What It’s Like To Work With Us

It’s not a rigid, five-step process. It’s more of a collaboration.

It usually starts with a simple phone call where you tell us what’s keeping you up at night. We’ll ask a lot of questions. If it sounds like we can actually help, we’ll map out a rough plan.

Then, we get into the weeds. We’ll get your CAD files and start building the model. We’ll probably have more questions. We’ll share early results and preliminary findings. This isn’t about a big, dramatic reveal at the end; it’s about figuring it out together, step-by-step.

We show our work. The final report is important, but it’s the conversation around it that matters more. We’ll walk you through everything, explain our reasoning, and make sure your team has what it needs to make the next decision.

Some of the folks we’ve helped:

By the Numbers:

- 473 Successful Projects Delivered

- Clients in over a dozen countries

- 93% of our work comes from repeat clients or referrals

“Honestly, I was skeptical about outsourcing our thermal analysis. We’d been burned before. The CFDSource team was different. Aris called me directly after the first run to point out a recirculation zone our own team had missed for two design cycles. That one insight saved us from a costly tooling change. They’re the real deal.”

— Peter Jenkins, Senior Mechanical Engineer, FlowMotion Dynamics

Think we might be a fit?

We’re not the right choice for everyone. We’re small, hands-on, and we get deeply involved. If that sounds like the kind of partnership you’re looking for, let’s talk.

The first call is just a conversation to see if your problem is something we’re good at solving. No sales pitch, no obligation.