ANSYS Fluent Projects: In the field of engineering dynamics and computational fluid dynamics, ANSYS Fluent is a basic and professional tool for this work. This software has made simulations a profession, providing engineers and researchers with the tools to perform complex simulations that address the nuances of fluid dynamics and heat transfer. In this article, ANSYS Fluent projects are reviewed in various industries and various applications and the vital role of this software in engineering developments are displayed for you.

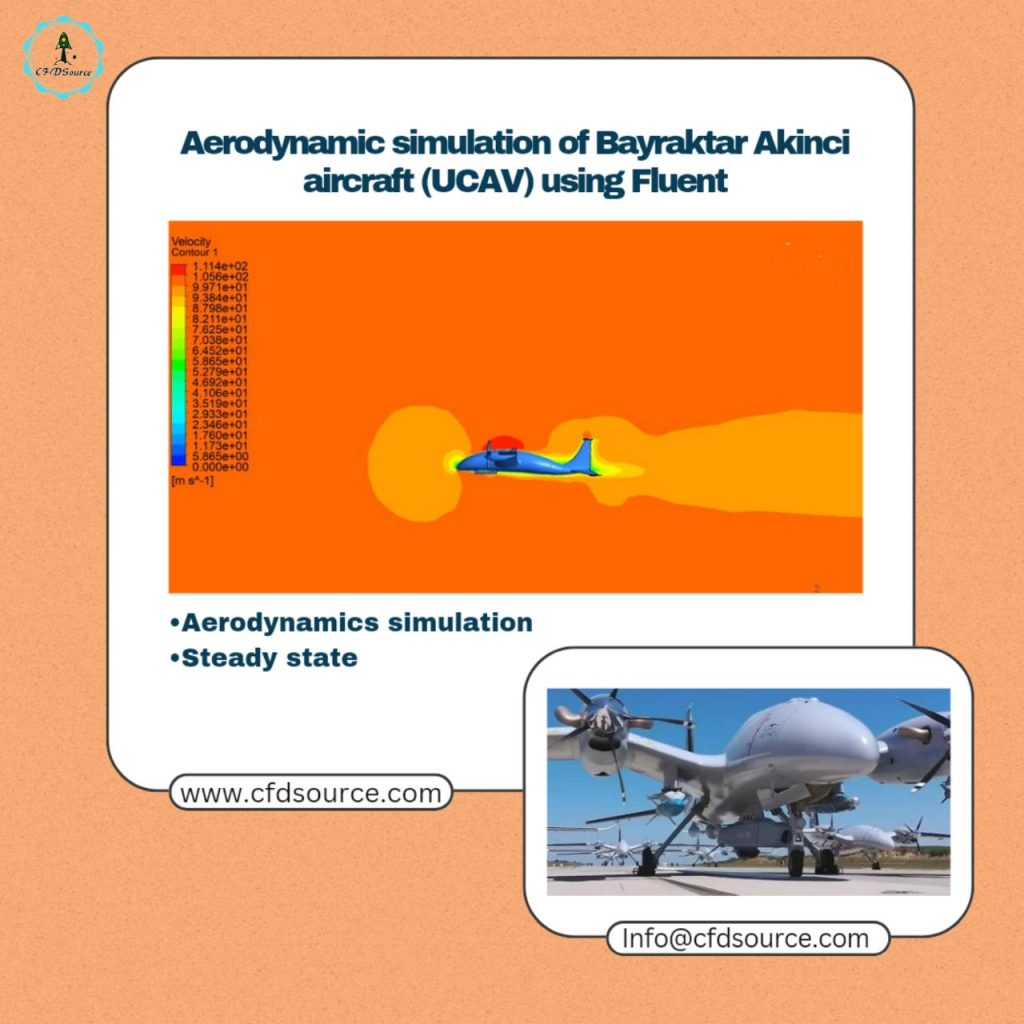

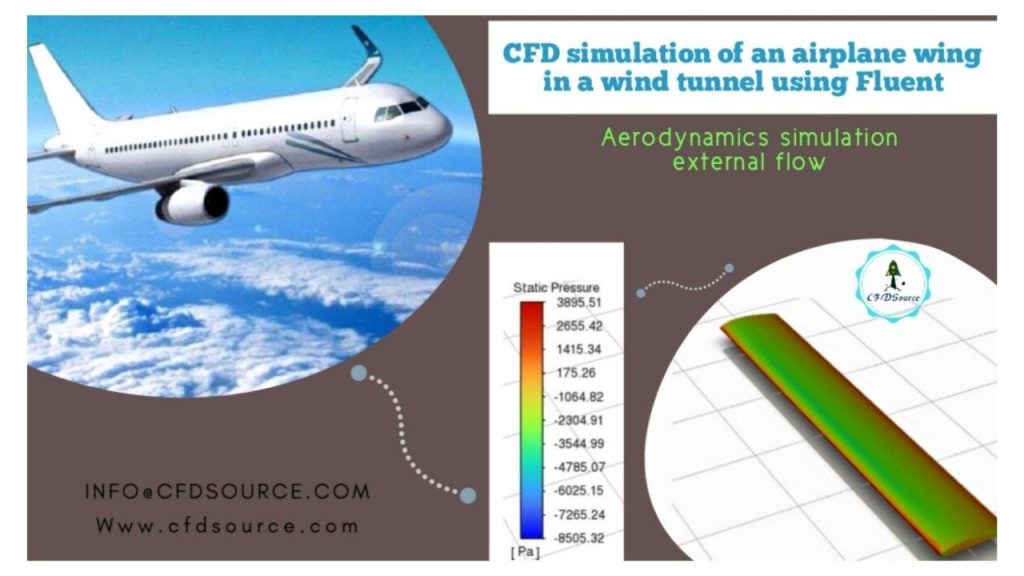

ANSYS Fluent Projects in Aerospace

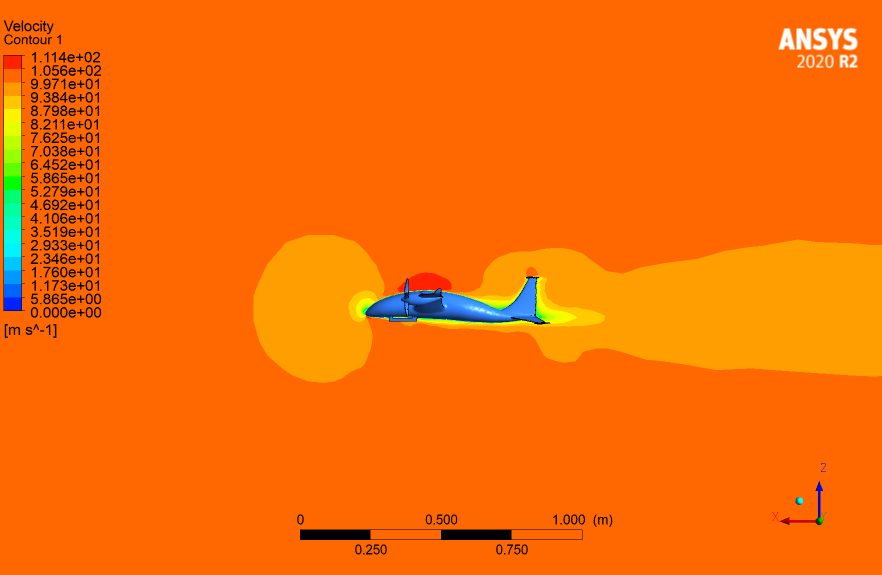

In the field of aerospace engineering, the accuracy and efficiency of various components are crucial. ANSYS Fluent, a computational fluid dynamics software, has a fundamental role in shaping the future of aviation. Aerospace engineers use this software to simulate and analyze data related to the complex interactions of fluids and heat in the field of designing airplanes and spacecraft according to the conditions. Supersonic, ANSYS Fluent allows engineers to fine-tune every detail of an aircraft’s motion and ensure safety, fuel efficiency, and optimal performance.

Supersonic aircraft are mostly known for breaking the sound barrier, but there are a series of unique engineering challenges, such as complex aerodynamic tuning that requires detailed analysis and optimization to reach and maintain supersonic speeds. Here, ANSYS Fluent is used by engineers by simulating the airflow pressure applied to the aircraft surfaces and optimizing design elements to reduce drag and increase its efficiency. Engineers can perform the necessary tests by designing different wing shapes, body design, and connecting and adjusting engine parts in an unrealistic environment, thus saving time and resources. This technology allows aerospace engineers to achieve the required balance between speed and fuel efficiency while ensuring that the aircraft remains safe and stable in flight.

Another important application of ANSYS Fluent in aerospace is the proper investigation of heat transfer. High speed in flight creates a lot of heat, especially in supersonic flight. ANSYS Fluent helps evaluate how heat is distributed in an aircraft and develop and develop the necessary strategies to manage it effectively. This is critical and necessary to maintain the safety and integrity of the aircraft structure, prevent overheating and thermal challenges. Performing thermal simulations allows engineers to fine-tune materials and cooling systems to provide the necessary resistance for the harsh conditions of supersonic flight.

In the aerospace industry, the scope of ANSYS Fluent goes beyond aircraft design. It is also very useful in designing the spacecraft and checking its re-entry into the atmosphere. This happens when the spacecraft encounters a very high temperature and pressure when re-entering the earth’s atmosphere. ANSYS Fluent simulations enable engineers to design the heat shield and predict and optimize it, enabling safe reentry and preserving the spacecraft structure. This software provides invaluable precision, as even the smallest design details can have a giant impact on ensuring the success and safety of space missions.

In short, ANSYS Fluent is the foundation of aerospace engineering as a tool, providing the tools engineers need to create safer, more efficient, and more innovative aircraft and spacecraft designs. From aerodynamic optimization to heat transfer management, this software enables engineers to tackle the specific challenges they face in the fast-paced world of aerospace. As the industry continues to push the frontiers of aerospace, ANSYS Fluent will remain an essential factor in achieving those lofty heights.

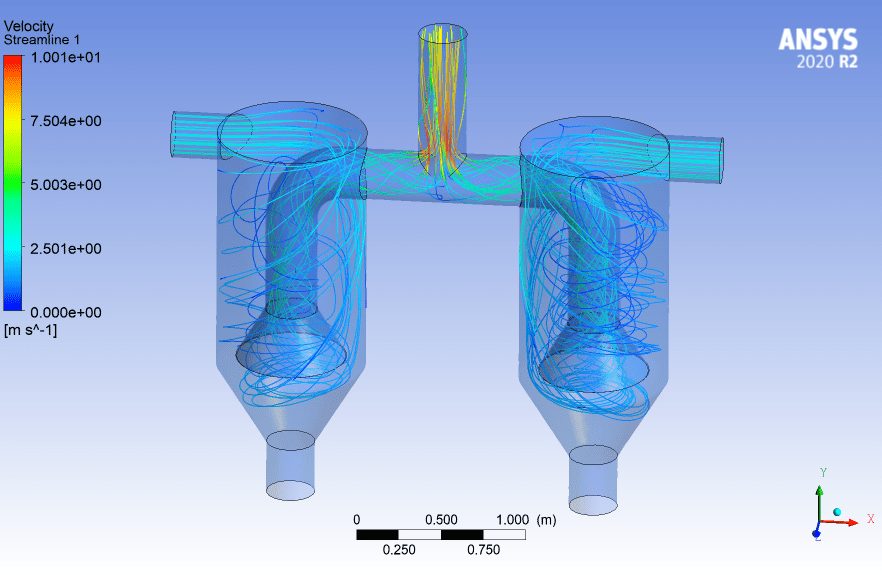

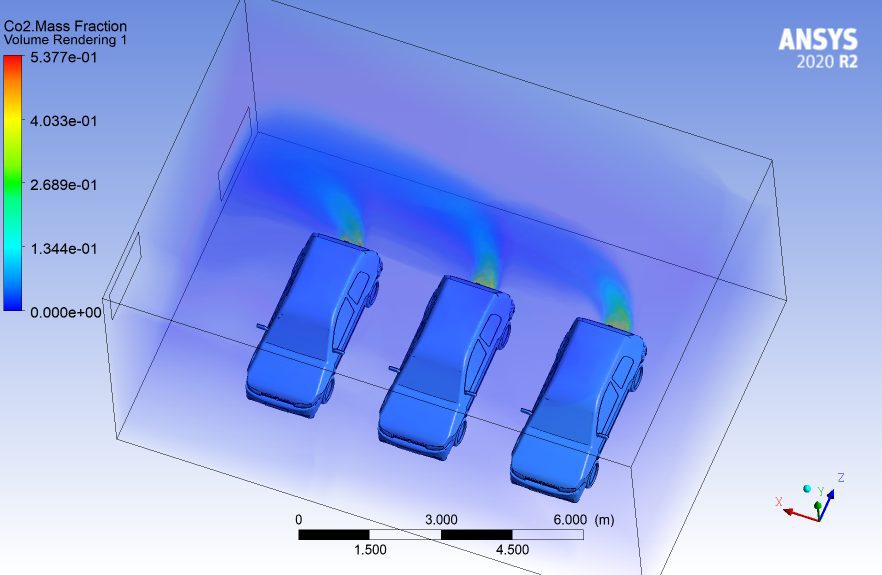

ANSYS Fluent Projects in the Automotive Industry

The automotive industry is in a never-ending race to improve vehicle performance, fuel efficiency and maintain sustainability. ANSYS Fluent, as a powerful computational fluid dynamics tool, plays an important role as a game changer in achieving these goals. This allows automotive engineers to delve deeply into the complex problems of fluid dynamics and succeed in designing and optimizing vehicles to reduce air resistance, increase aerodynamics, and ultimately increase fuel efficiency.

One of the essential subjects in which ANSYS Fluent proves its value is the optimization of vehicle aerodynamics. When a vehicle is in motion, it encounters the force of air resistance, which affects fuel consumption and the overall performance of the vehicle. Engineers use ANSYS Fluent to simulate the effect of air flow around the car and investigate how design changes can make the car face less drag. By modifying and changing the shape of the car, including changes in factors such as body shape, mirrors, and even the placement of antennas, engineers can greatly reduce the force of incoming air resistance. This leads to saving fuel consumption and reducing its effects on the environment.

Consider a case study on improving vehicle fuel efficiency. ANSYS Fluent simulations show how small design changes can have a significant impact on overall vehicle performance. By modifying the shape of the car body and optimizing its aerodynamics, engineers were able to reduce drag and improve fuel efficiency by more than 10 percent. Such changes can greatly reduce costs for consumers and also significantly prevent greenhouse gases from entering the atmosphere. ANSYS Fluent enables automotive engineers to achieve a precise balance between vehicle appearance and performance.

Going beyond aerodynamics, ANSYS Fluent also plays an essential role in optimizing fluid dynamics inside vehicles. Optimizations such as designing efficient cooling systems, which are necessary to maintain optimal temperature balance for proper engine operation, are handled by ANSYS Fluent. By simulating the movement of coolant flow through the engine and radiator, engineers can identify potential hot spots. And identify and strengthen areas where there is a possibility of improving heat transfer. This level of precision and attention to detail ensures that the vehicles maintain their optimal performance in various conditions, from stop and go in the city to long journeys.

In short, ANSYS Fluent is revolutionizing the automotive industry by giving engineers new capabilities to make data-driven decisions to achieve optimal fuel efficiency, performance, and sustainability. From reduced air resistance through aerodynamic improvements to improved engine cooling systems, this software has proven to be critical to creating environmentally friendly and optimally performing vehicles. As the automotive industry continues to evolve, ANSYS Fluent will also remain a major factor in shaping the vehicles of the future.

ANSYS Fluent Projects in the Energy Sector

In the energy sector, which is always expanding, the importance of exploiting renewable energy sources and optimizing energy production are important issues that must be paid attention to. ANSYS Fluent, a versatile computational fluid dynamics software, has played an influential role in various energy-related projects. From designing wind turbines to manufacturing high-efficiency solar panels, ANSYS Fluent allows engineers and researchers to simulate and analyze fluid flow and heat transfer to ensure that energy production is both efficient and effective. It is sustainability.

Wind energy is one of the most promising types of renewable energy in the future, and ANSYS Fluent plays an important role in the optimal design of wind turbines. Wind turbines are under a wide range of environmental conditions and their efficiency depends on the aerodynamic quality of its blades. ANSYS Fluent allows engineers to optimize blades for maximum energy absorption by simulating the amount of airflow over the blades and simulating their shape and orientation. This software provides a long and complete understanding of fluid dynamics in this field and enables engineers to succeed in designing more efficient and reliable wind turbines.

The energy sector also depends on fluid flow simulation to improve the efficiency of energy generation and energy transfer. For example, in hydroelectric power plants, the use of ANSYS Fluent can lead to modeling and optimization of water flow through turbines and guarantee that the amount of energy production will be maximized. Moreover, in the design of nuclear power plants, ANSYS Fluent is used to analyze the performance of cooling systems and optimize safe and efficient performance.

The energy sector also depends on fluid flow simulation to improve the efficiency of energy generation and energy transfer. For example, in hydroelectric power plants, the use of ANSYS Fluent can lead to modeling and optimization of water flow through turbines and guarantee that the amount of energy production will be maximized. Moreover, in the design of nuclear power plants, ANSYS Fluent is used to analyze the performance of cooling systems and optimize safe and efficient performance.

In short, ANSYS Fluent is a fundamental factor in energy generation and transmission, making the transition to renewable energy sources even more possible! And increases the amount of energy distribution. This software allows engineers to make the right decisions in issues such as the optimal performance of wind turbines, improving the performance of solar panels and ensuring the safe operation of power plants, searching for sustainable and efficient energy solutions. As the world’s priority continues to be cleaner and more consistent energy production, ANSYS Fluent will continue to be at the forefront of this sector.

ANSYS Fluent Projects in Biomedical Engineering

The intersection of two fields of engineering and medicine has created the field of medical engineering, where innovation and accuracy are of great importance. ANSYS Fluent, a computational fluid dynamics software, has proven its place in this field and helps to advance in medical research and research, drug effectiveness, and the design and production of medical devices. Biomedical engineers use ANSYS Fluent to simulate and analyze the flow of human body fluids and use it as an important tool to overcome the various challenges they face in healthcare.

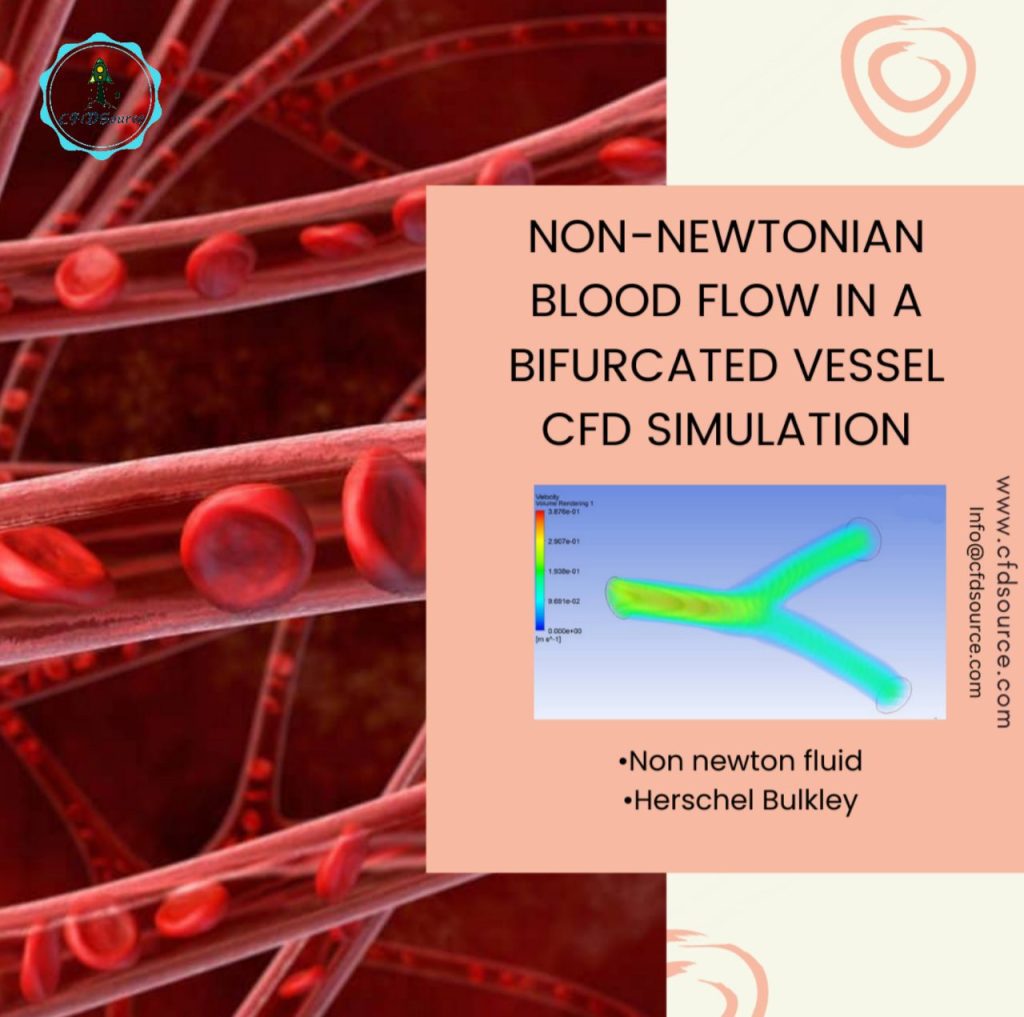

One of the significant applications of ANSYS Fluent in medical engineering is that engineers simulate the movement of blood flow. The importance of this work is due to the understanding of blood flow in the circulatory system for cardiovascular research and the development of medical research. ANSYS Fluent enables researchers to create accurate models of blood flow motion by considering factors such as vessel geometry, blood viscosity, and the impact of various medical conditions. These simulations lead to providing new insights about how blood flows in arteries and veins and are effective in diagnosing and treating disorders that exist in blood circulation. Researchers can also use ANSYS Fluent to optimally design and manufacture medical devices such as stents, ensuring they improve blood flow and minimize side effects.

In addition, ANSYS Fluent plays an important role in the field of timely drug effects in body organs. When developing new drugs, understanding how they behave in body fluids is essential. ANSYS Fluent enables researchers to help refine drug effects by simulating how drugs move and spread throughout the body. By optimizing the design of drug delivery devices, researchers can increase the effectiveness of drug treatments while greatly reducing side effects.

In the field of dentistry and orthodontics, ANSYS Fluent can be effective in simulation to understand the flow of liquids in the oral cavity. The importance of this is especially where to understand the effect of different types of dental equipment, orthodontic devices on fluid dynamics, helping to improve the design of the device. And their specific treatments can have a special effect.

In short, ANSYS Fluent has an undeniable place in medicine, giving researchers and engineers the ability to address the complex challenges that exist in medicine and healthcare. Things like simulating blood flow to conduct cardiovascular research, optimizing the effectiveness and release of drug substances and improving the design of medical devices, this software has given biomedical engineers the opportunity to find efficient solutions to improve patient care and Overall, increase the quality of life. As mankind continues to progress in the field of medical engineering, ANSYS Fluent will be a very efficient tool to advance these new goals.

Challenges and Benefits

While ANSYS Fluent projects include many benefits, they also face certain challenges. Understanding them and reaching appropriate solutions for these challenges to fully utilize the many advantages of this computational fluid dynamics software is something that should always be considered.

One of the major challenges we face is the requirements for complex setups for ANSYS Fluent simulations. Creating a simulation, especially for complex projects such as designing a hypersonic aircraft or biomedical fluid flow, requires a high understanding of the software capabilities and physics of the system being modelled. This can be time-consuming for engineers and may require specialized training for engineers and researchers involved in these simulations.

Additionally, ANSYS Fluent projects often demand significant computational power. Running simulations, especially those involving large and complex models, can strain computing resources. High-performance computing clusters or powerful workstations are often required to ensure that simulations are completed in a reasonable timeframe. Acquiring and maintaining these resources can be a significant investment.

Interpreting the results of ANSYS Fluent simulations can also pose a challenge. The software provides a wealth of data, and it takes expertise to translate these results into actionable insights. Engineers and researchers must be well-versed in both the software and the specific field of study to make informed decisions based on the simulation outcomes.

Despite these challenges, the benefits of ANSYS Fluent projects far outweigh the difficulties. Engineers can benefit from real-time feedback on their designs, allowing them to make improvements rapidly. By fine-tuning designs within a virtual environment, the software reduces the need for costly and time-consuming physical prototyping. This not only saves resources but also accelerates the development process, resulting in more efficient and innovative solutions.

Additionally, ANSYS Fluent enhances the ability to conduct detailed and precise simulations. Engineers can gain insights into fluid dynamics, heat transfer, and other critical factors that are often impossible to measure directly in real-world experiments. This level of precision allows for the optimization of designs, ensuring they meet safety and performance standards. ANSYS Fluent empowers engineers to explore innovative solutions, fine-tune existing designs, and remain at the forefront of technological advancements in their respective fields.

In summary, while ANSYS Fluent projects may present challenges in terms of setup, computational resources, and result interpretation, the benefits they bring to the engineering and research processes are substantial. The software’s ability to provide real-time feedback, optimize designs, and offer precise simulations make it an invaluable tool for engineers and researchers across diverse industries.

Conclusion

ANSYS Fluent Projects: ANSYS Fluent has revolutionized engineering simulations across multiple industries, from aerospace to biomedical engineering. Its ability to provide in-depth insights into fluid dynamics and heat transfer is unmatched, allowing engineers to create safer, more efficient, and innovative designs. As industries continue to evolve, ANSYS Fluent will remain a cornerstone in the world of engineering simulations.