Introduction

CFD for Chemical Engineers: In the dynamic realm of chemical engineering, where precision and efficiency are paramount, the integration of Computational Fluid Dynamics (CFD) has emerged as a game-changer. CFD, a sophisticated simulation technique, plays a pivotal role in understanding and optimizing fluid flow, heat transfer, and mass transfer processes. At its core, CFD utilizes advanced mathematical models and numerical algorithms to simulate the behavior of fluids in various engineering applications.

The importance of CFD in modern engineering cannot be overstated, as it provides engineers with a virtual laboratory to analyze and predict complex fluid dynamics scenarios without the need for costly physical prototypes. As we embark on this exploration of CFD in chemical engineering, we delve into the fundamental principles and applications that make it an indispensable tool for engineers seeking precision and efficiency in their processes.

Basics of CFD

Before delving into the specifics of CFD’s applications, it’s essential to grasp the fundamentals. Computational Fluid Dynamics involves the numerical simulation of fluid and thermal behavior, offering insights into complex engineering problems. At its core, CFD relies on mathematical modeling and computer-aided simulations to analyze and predict the dynamic behavior of fluids. The key principles revolve around solving the governing equations of fluid flow, including the Navier-Stokes equations, using numerical methods.

This allows engineers to visualize and understand how fluids behave in various scenarios, aiding in the design and optimization of processes. The significance of CFD in chemical engineering lies in its ability to provide a detailed understanding of fluid dynamics, heat transfer, and mass transfer, which are crucial aspects of chemical processes.

Applications of CFD in Chemical Engineering

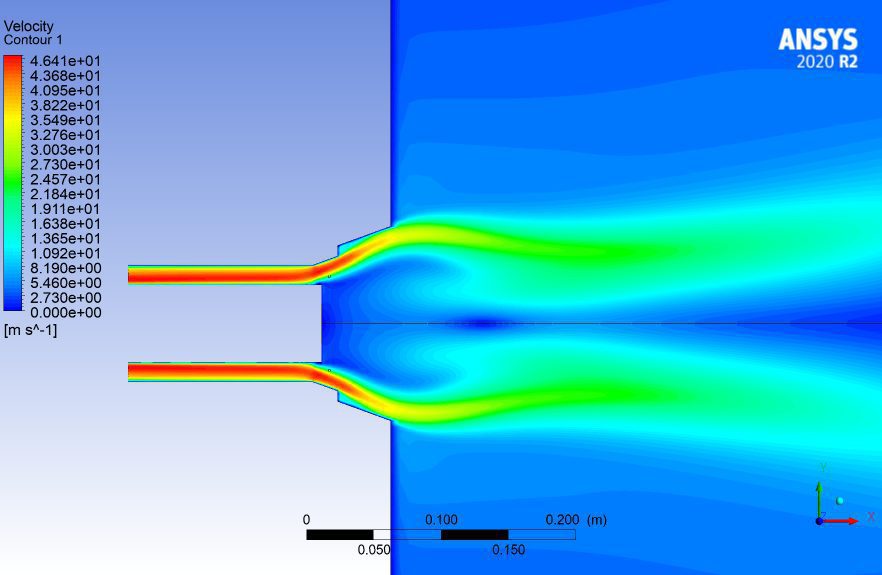

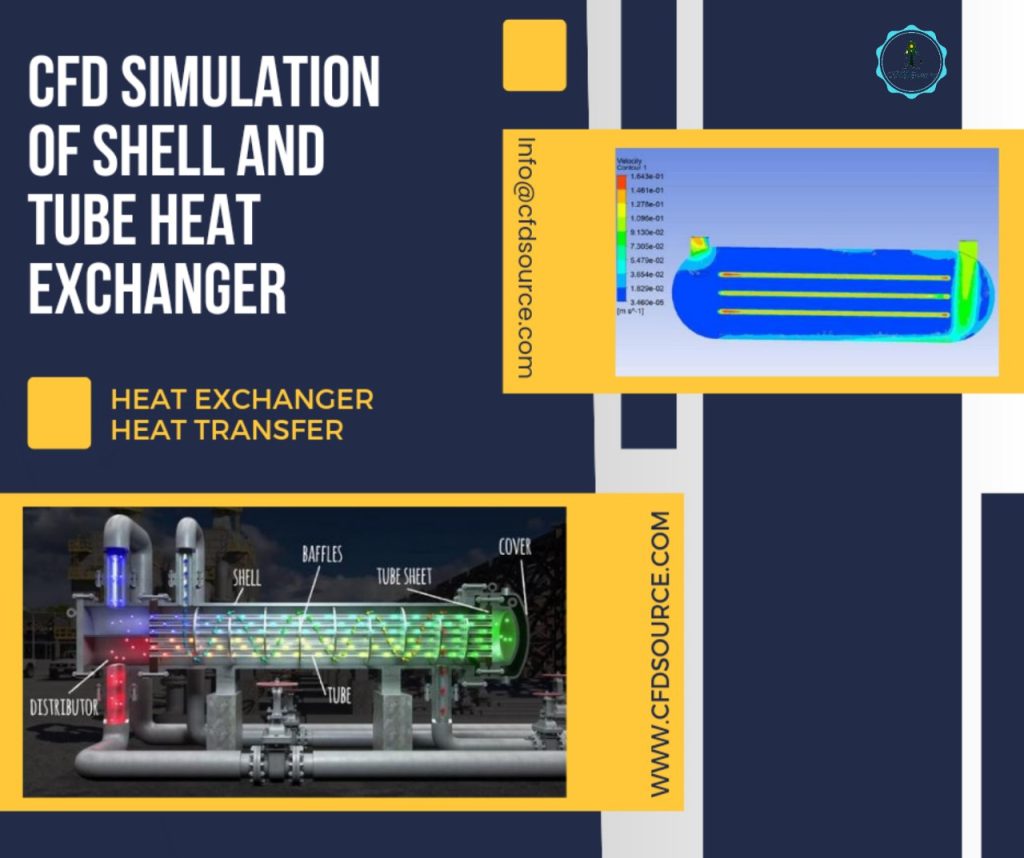

The versatility of CFD becomes evident in its applications within chemical engineering. From fluid flow analysis to heat and mass transfer simulations, CFD empowers engineers to optimize processes, ensuring efficiency and reliability. Fluid flow analysis, a cornerstone application, allows engineers to predict how liquids or gases will behave within a system, aiding in the design of pipelines, reactors, and mixing vessels. Heat transfer studies using CFD enable the optimization of heat exchangers and other thermal devices.

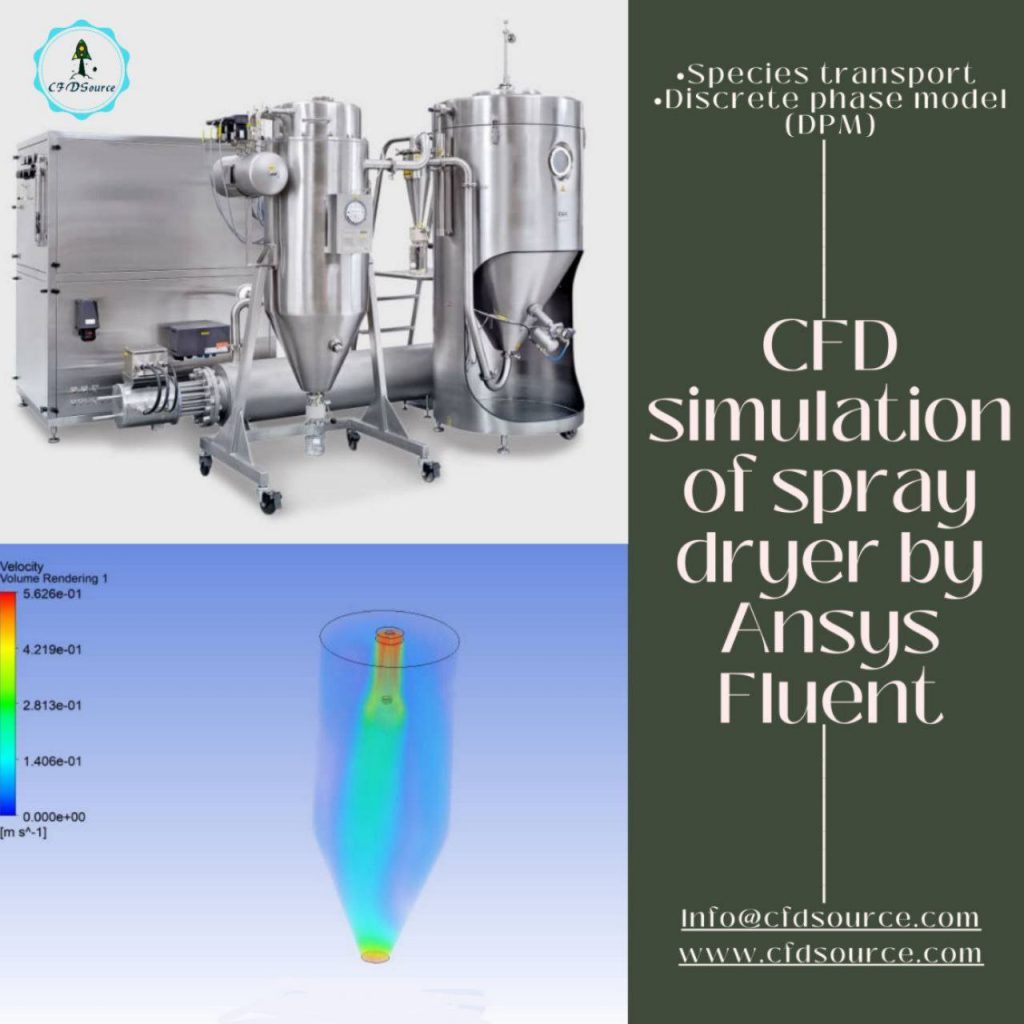

Additionally, mass transfer simulations provide insights into the movement of chemical species within a system, crucial for understanding reaction kinetics. The applications of CFD in chemical engineering extend beyond theoretical understanding, directly influencing the design, operation, and optimization of processes, making it an invaluable tool for practitioners in the field.

CFD Software in Chemical Engineering

Navigating the vast landscape of CFD software can be overwhelming. This section provides an overview of popular CFD software, outlining their features and advantages. CFD software serves as the bridge between complex mathematical models and practical engineering applications. Popular software like ANSYS Fluent, COMSOL Multiphysics, and OpenFOAM offer engineers a diverse set of tools to simulate fluid dynamics, heat transfer, and chemical reactions.

The choice of software depends on the specific needs of the engineering task, computational resources available, and the level of detail required in simulations. Understanding the capabilities of these tools is crucial for chemical engineers aiming to harness the power of CFD in their projects. The integration of CFD software into the workflow not only enhances the precision of analyses but also accelerates the design and optimization processes in chemical engineering.

CFD for Process Optimization

One of the primary benefits of CFD lies in its ability to optimize processes, a crucial aspect explored in this section. CFD for process optimization involves using computational simulations to refine and enhance chemical engineering operations. By modeling fluid dynamics, heat transfer, and mass transfer within a system, engineers can identify areas for improvement and implement changes to maximize efficiency. Real-life examples illustrate how CFD has been instrumental in enhancing efficiency, reducing costs, and mitigating risks in various industrial processes.

Whether it’s optimizing the design of a chemical reactor, improving heat exchanger performance, or streamlining the flow within a pipeline, CFD provides a virtual testing ground where engineers can explore different scenarios without the need for physical prototypes. This section delves into the tangible benefits of utilizing CFD for process optimization, demonstrating its transformative impact on the field of chemical engineering.

Challenges and Solutions

Despite its transformative potential, CFD comes with its set of challenges, as explored in this section. Common challenges in CFD applications include computational bottlenecks, the need for accurate input data, and model validation. Addressing these challenges is crucial for successful implementation and ensuring the reliability of simulation results. The section not only highlights these challenges but also delves into innovative solutions that push the boundaries of CFD applications.

From advancements in numerical algorithms to the integration of artificial intelligence, engineers are continually developing strategies to overcome obstacles and enhance the accuracy and efficiency of CFD simulations. By acknowledging and understanding these challenges, chemical engineers can navigate the complexities of CFD with confidence, leveraging its capabilities while minimizing potential pitfalls.

Future Trends

The journey of CFD in chemical engineering is far from static, and this section explores the emerging trends and future developments in the field. As technology advances, so does the role of CFD in shaping the future of chemical engineering. From the incorporation of machine learning to the rise of cloud-based simulations, new technologies are poised to reshape the landscape. This section provides insights into these emerging trends, offering readers a glimpse into the tools and methodologies that will likely play a significant role in the future of CFD. Anticipated developments, such as increased automation, improved scalability, and enhanced predictive capabilities, underscore the ongoing evolution of CFD and its continued relevance in addressing complex engineering challenges.

Case Studies

CFD for Chemical Engineers: Learning from practical examples is invaluable, and this section delves into case studies that showcase successful implementations of CFD in chemical engineering projects. These real-world examples provide a nuanced understanding of how CFD can be applied to solve complex problems and drive innovation. Whether it’s optimizing the performance of a chemical reactor, improving the efficiency of a heat exchanger, or designing a more effective mixing process, case studies offer tangible evidence of the impact of CFD on real-world engineering challenges.

By examining these cases, readers gain insights into the practical benefits, lessons learned, and potential pitfalls of implementing CFD in their own projects. Each case study serves as a testament to the versatility and effectiveness of CFD as a tool for problem-solving and optimization in chemical engineering.

Advantages and Limitations

Understanding the advantages and limitations of utilizing CFD in chemical engineering is essential for practitioners in the field. This section provides a comprehensive exploration of the benefits that come with integrating CFD into engineering workflows. From increased accuracy in predicting fluid dynamics to the ability to optimize processes without physical prototypes, the advantages of CFD are diverse and impactful.

The section also delves into the limitations and considerations that engineers must bear in mind when using CFD. Challenges such as the need for high computational resources, potential inaccuracies in modeling, and the importance of validation are discussed. Striking a balance between leveraging the advantages and navigating the limitations is key for successful implementation, and this section equips readers with the insights necessary to make informed decisions in their engineering endeavors.

Training and Skill Development

Acquiring proficiency in CFD is an ongoing process, and this section emphasizes the importance of training and skill development for chemical engineers. While CFD software provides powerful tools, understanding how to effectively utilize them requires a solid foundation in the underlying principles and techniques. The section outlines the importance of formal training programs, workshops, and online resources in enhancing the skills of engineers. Recommendations for specific courses, certifications, and learning platforms cater to both beginners and experienced professionals looking to deepen their understanding of CFD. By investing in training and skill development, chemical engineers can unlock the full potential of CFD, ensuring that they can navigate the complexities of fluid dynamics and simulation with confidence and proficiency.

Industry Insights

Perspectives from leading chemical engineers shed light on the industry’s reception and adoption of CFD technology in this section. Real-world experiences and insights into how CFD has influenced day-to-day operations provide a nuanced understanding of its impact on the field. Industry experts discuss the challenges they’ve faced, the successes they’ve achieved, and the evolving role of CFD in shaping the landscape of chemical engineering.

Whether it’s streamlining production processes, optimizing equipment design, or improving safety measures, industry insights offer valuable lessons and inspiration for professionals seeking to integrate CFD into their own projects. The diverse perspectives presented in this section create a holistic view of CFD’s role in the industry, showcasing both its current impact and its potential for future innovations.

Environmental Impact

In an era of heightened environmental awareness, this section explores how CFD contributes to sustainable practices in chemical engineering. Reducing the environmental footprint through optimized processes aligns CFD with the broader goals of eco-friendly engineering practices. The section highlights specific ways in which CFD can be leveraged to enhance sustainability, such as minimizing energy consumption, reducing waste production, and improving the overall efficiency of chemical processes.

By examining the environmental impact of CFD applications, chemical engineers can make informed decisions that align with the growing emphasis on sustainability in the field. This section aims to inspire professionals to consider the ecological implications of their work and leverage CFD as a tool for environmentally conscious engineering practices.

CFD in Research and Development

The role of CFD extends beyond routine operations, playing a crucial part in driving innovations in research and development within chemical engineering. This section delves into the ways in which CFD serves as a catalyst for advancements in various research areas. From studying the behavior of novel materials in fluid environments to optimizing cutting-edge technologies, CFD provides a virtual laboratory for researchers to explore and understand complex phenomena.

The section highlights instances where CFD has been instrumental in pushing the boundaries of knowledge, fostering breakthroughs in areas such as nanotechnology, bioengineering, and materials science. By offering a platform for virtual experimentation, CFD accelerates the pace of research and development, empowering scientists and engineers to explore new frontiers and contribute to the evolving landscape of chemical engineering.

Case for Collaboration

Interdisciplinary collaboration emerges as a linchpin for holistic advancements in engineering in this section. By making a compelling case for collaborative approaches, the article emphasizes how partnerships between CFD experts and professionals from diverse fields amplify the impact of CFD in chemical engineering. Whether collaborating with materials scientists, biotechnologists, or environmental engineers, the synergies generated through interdisciplinary teamwork lead to comprehensive problem-solving and innovative solutions.

The section showcases successful collaborative projects, highlighting the unique insights and expertise each discipline brings to the table. It underscores the idea that, in a world of increasing complexity, solving intricate engineering challenges requires a collective effort that draws on the strengths of various specialties. The case for collaboration resonates as a call to action, encouraging chemical engineers to embrace interdisciplinary approaches and leverage the full potential of CFD in tandem with other fields.

Conclusion

CFD for Chemical Engineers: In conclusion, the integration of CFD in chemical engineering is a transformative force, empowering professionals to navigate the complexities of fluid dynamics with precision. As we reflect on the myriad applications, challenges, and future trends explored in this article, it becomes evident that CFD is not merely a tool but a catalyst for innovation in the ever-evolving landscape of chemical engineering.

From optimizing processes to driving research and development, CFD has become an indispensable asset. The insights gained from industry experts, case studies, and collaborative endeavors underscore the multifaceted impact of CFD. As the field continues to evolve, chemical engineers are presented with both challenges and opportunities to harness the power of CFD for enhanced efficiency, sustainability, and innovation.