CFD for HVAC: In the world of heating, ventilation and air conditioning (HVAC), achieving comfort and obtaining the desired energy efficiency is a constant need. One of the valuable tools that has revolutionized the HVAC industry is Computational Fluid Dynamics (CFD) analysis. This article examines the power of CFD in HVAC system design and how to increase its profit and performance and energy efficiency.

1. Introduction to CFD for HVAC

In the field of heating, ventilation and air conditioning (HVAC), achieving the perfect balance between comfort and overall energy efficiency has long been a challenge. However, the advent of computational fluid dynamics (CFD) analysis has provided HVAC engineers with a powerful tool to meet this challenge. CFD, in essence, is a simulation technique that allows us to reconstruct and analyze fluid flow and heat transfer in HVAC systems. It provides engineers with unprecedented insight into the complex dynamics of air and temperature distribution, making it a game-changer for industry.

Air conditioning systems are one of the main factors in closed and habitable environments where people live, work and play. They maintain the temperature, humidity and air quality and make the spaces comfortable and conducive to doing different things. However, achieving this balance while minimizing energy consumption has been a long-standing struggle. The introduction of CFD to the air conditioning arena means that we can now simulate and analyze how air flows, how heat is distributed, and how pollutants disperse in these systems, all without relying solely on physical tests.

2. What is CFD Analysis?

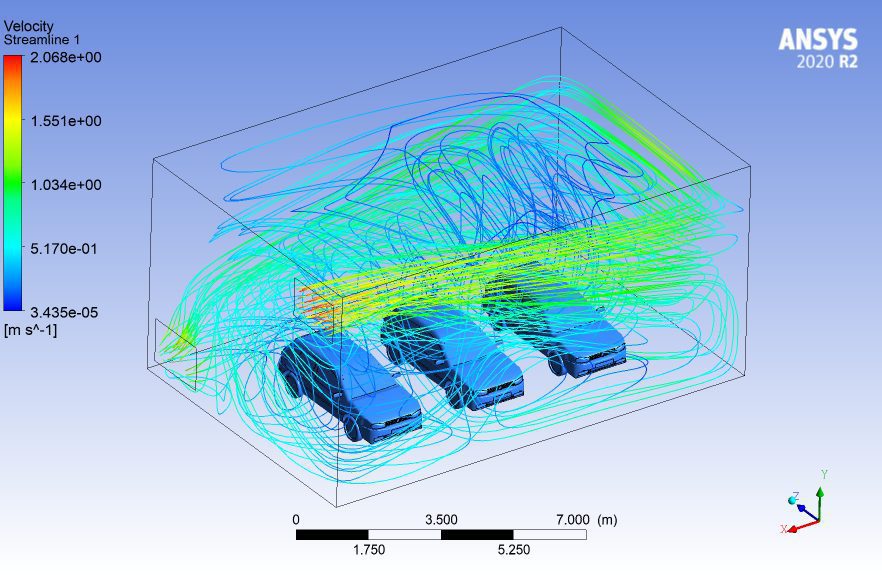

Understanding CFD analysis is critical to understanding its application in HVAC. CFD or Computational Fluid Dynamics is a branch of fluid mechanics that uses numerical methods and algorithms to solve and analyze problems related to fluid flow and heat transfer. In the HVAC field, it involves creating a realistic model of the system using specialized software. This model, known as the computational domain, represents the physical components of the HVAC system, such as ductwork, air handlers, and heat exchangers. The unreal system is then subjected to a series of mathematical simulations that simulate real-world conditions. These simulations provide valuable insights into how air moves through the system, how temperature is distributed, and how various design changes affect performance.

One of the most important benefits of CFD analysis is its ability to provide an accurate and visual representation of HVAC system behavior. Engineers can observe how air flow moves through ducts, how heat is exchanged, and even how pollutants settle in the environment. This level of insight is almost impossible to achieve through physical experiments alone. CFD essentially creates an unreal laboratory where designers and engineers can test multiple scenarios and variables, making it an essential tool for optimizing HVAC systems.

3. Significance of CFD Analysis in HVAC

The importance of CFD analysis in the HVAC industry cannot be overstated. Traditional and old air conditioning designs are largely dependent on basic and simple rules and experiences. While these methods have produced functional systems, they often fall short of providing optimal performance. This is where CFD comes in, providing precision that was previously unimaginable.

CFD It allows engineers to understand the intricate details of fluid flow, heat transfer and air quality in HVAC systems. It provides accurate predictions about how the air will circulate in the room, how the temperature will fluctuate, and how the pollutants will spread. This insight enables engineers to make data-driven decisions, leading to more efficient and effective HVAC system design.

The importance of CFD analysis becomes even more apparent when considering the energy efficiency and environmental impact of HVAC systems. In a world where energy sustainability is a major concern, reducing energy consumption is of great importance. CFD enables engineers to identify energy-saving opportunities by fine-tuning the design of HVAC systems, resulting in significant cost savings and reduced carbon footprints.

4. How CFD Enhances HVAC System Design

CFD enhances HVAC system design with a level of precision and insight that older design methods simply cannot match. Through CFD simulation, engineers can visualize how air moves in ducts, how temperature gradients form, and how pollutants disperse. This visualization enables them to make informed design decisions and optimize HVAC systems for maximum performance.

One of the key ways that CFD enhances HVAC design is by helping engineers address challenges related to airflow distribution. Adequate air flow is essential to maintaining comfortable indoor conditions and ensuring efficient heating and cooling. CFD simulations can identify areas of turbulence, pressure differences, and areas of insufficient airflow. Engineers can then modify system components, such as ducts and diffusers, to improve air distribution and increase overall comfort and efficiency.

In addition to airflow, CFD analysis can optimize heat transfer in HVAC systems. Heat exchangers play an important role in temperature control, and CFD simulations can identify areas where heat transfer is not going well, allowing engineers to tune these components for greater efficiency. By fine-tuning heat exchangers and other system elements, HVAC designers can achieve better performance with this energy and reduce process costs.

CFD analysis also helps to improve indoor air quality. It can model the spread of pollutants, allergens, or contaminants in a space and help engineers design systems that effectively eliminate or reduce the presence of these substances. This is especially important for healthcare centers, laboratories and other environments where air quality is a very important issue.

In summary, CFD improves HVAC system design by providing accurate and varied perspectives on airflow, heat transfer, and air quality. It enables engineers to create more efficient, cost-effective and environmentally friendly air conditioning systems that provide optimal indoor air quality and comfort.

5. The Role of Simulation in HVAC CFD Analysis

Simulation plays an essential role in HVAC CFD analysis, acting as a bridge between design fundamentals and real-world performance. This allows engineers to create a digital twin of the HVAC system and replicate the behavior of the fluids and gases within it. This digital mockup becomes a theoretical laboratory where engineers can test design parameters and operating conditions in different situations. Through simulation, engineers can predict how the HVAC system will perform, discover fundamental issues, and accurately plan their designs and theories. This proactive approach greatly reduces the risk associated with HVAC system design, as problems can be identified and fixed in the laboratory under unrealistic conditions, saving time and resources compared to old-fashioned trial-and-error methods saved.

In addition, the role of simulation increases to investigate and analyze different scenarios and increase the improvement in the performance of the HVAC system. Engineers can test how the system reacts to changes in temperature, air flow rate, or even the supply of new equipment. This will not only help future designs in this area, but also help troubleshoot current systems. Simulation helps identify underperforming and faulty components and allows for improved targeting, which significantly increases the overall efficiency and effectiveness of the HVAC system.

6. Benefits of Using CFD in HVAC

The advantages of using Computational Fluid Dynamics (CFD) in the field of air conditioning have various and wide dimensions. One of the most important advantages is to optimize the way energy is used. CFD allows engineers to adjust the design of HVAC systems to improve airflow, heat transfer, and enhance ambient air quality. By doing this, systems work more efficiently and reduce energy consumption and process costs. This is a critical factor in today’s world, where concerns about energy sustainability and environmental compatibility drive the need for more environmentally friendly air conditioning solutions.

Another significant benefit is the improvement of indoor air quality. CFD allows engineers to simulate the dispersion of pollutants in environments, pollutants and allergens in a space. With this information, they can design HVAC systems that effectively remove or discourage these substances, creating healthier and more comfortable indoor environments. This is especially necessary in environments such as hospitals and laboratories where air quality directly affects human health.

CFD also helps extend the life of HVAC systems. By increasing improvements in design, engineers can reduce component wear and tear, increase their lifespan, and reduce maintenance costs. This is particularly beneficial for commercial and industrial air conditioning systems, where equipment replacement can be significant.

In addition, CFD helps increase design efficiency and accuracy. Old air conditioner design often implies rules of thumb that can lead to inappropriate results. CFD, on the other hand, provides a level of detail and accuracy that ensures the design matches some specific requirements of the intended space. This precision results in systems that offer a high level of comfort and fit, making them especially valuable in applications such as residential heating and cooling.

7. Challenges and Considerations

In addition, CFD helps increase design efficiency and accuracy. Old air conditioner design often implies rules of thumb that can lead to inappropriate results. CFD, on the other hand, provides a level of detail and accuracy that ensures the design matches some specific requirements of the intended space. This precision results in systems that offer a high level of comfort and fit, making them especially valuable in applications such as residential heating and cooling.

Another point is to choose the right models. CFD simulations rely on mathematical models to represent physical phenomena. Engineers must choose models that best describe the behavior of fluids and gases in the HVAC system. Choosing the wrong model can lead to incorrect results and hinder the effectiveness of previous analyses.

Validation is also a very important step. Engineers must compare CFD results with real-world data to ensure simulations are correct. It requires a set of measurements, such as the intensity and size of air flow and temperature distribution, in the physical system. Differences between simulated and observed real-world data can identify areas where the model or input data need to be modified.

Validation is also a very important step. Engineers must compare CFD results with real-world data to ensure simulations are correct. It requires a set of measurements, such as the intensity and size of air flow and temperature distribution, in the physical system. Differences between simulated and observed real-world data can identify areas where the model or input data need to be modified.

So, while CFD analysis offers several advantages, addressing these challenges and considerations is necessary to ensure the reliability of the system and the accuracy of the results. Proper data collection, model selection, validation, and access to the required computational resources are all key factors in the successful application of CFD in HVAC design.

8. Applications of CFD in HVAC Design

The applications of Computational Fluid Dynamics (CFD) in HVAC design are diverse and cover a wide range of industries. CFD is not limited to just one aspect of HVAC, but can be used throughout the entire system, from the air handling units to the distribution network. For example, CFD can be used to improve duct design, ensuring air flow and temperature distribution are uniform within a building. It can also help design effective air handling units, help balance incoming and outgoing air, and minimize energy consumption.

The applications of Computational Fluid Dynamics (CFD) in HVAC design are diverse and cover a wide range of industries. CFD is not limited to just one aspect of HVAC, but can be used throughout the entire system, from the air handling units to the distribution network. For example, CFD can be used to improve duct design, ensuring air flow and temperature distribution are uniform within a building. It can also help design effective air handling units, help balance incoming and outgoing air, and minimize energy consumption.

CFD can also play an important role in the optimal operation of heat exchangers. These parts are very important for temperature control in HVAC systems. CFD simulations can identify areas where heat transfer is not being performed properly and recommend design changes that will properly increase performance. This ensures that air conditioning systems work at maximum efficiency, saving energy and operating costs. Additionally, CFD is used to evaluate the performance of filtration systems. Clean air is essential to maintaining indoor air quality, and CFD can help engineers understand how different filtration methods capture and remove airborne pollutants from the supply air. This information is very important for choosing suitable filtration solutions for its application in specific places such as hospitals, laboratories or industrial facilities.

9. Conclusion

As a result, computational fluid dynamics (CFD) has emerged as a highly influential force in the field of heating, ventilation, and air conditioning (HVAC). It provides engineers and designers with a powerful tool for useful analysis and optimization of HVAC systems for superior performance, energy efficiency and improved indoor air quality. By creating virtual copies of these systems, CFD simulations provide valuable insight into airflow path patterns, temperature distribution, and dispersion of ambient pollutants. This knowledge enables engineers to make design decisions based on the data provided, ensuring that HVAC systems not only meet but exceed comfort and efficiency expectations.

While challenges such as data accuracy and model selection continue Important topics in this field, the benefits of using CFD in HVAC design are significant, including reduced energy consumption, improved indoor air quality, and increased equipment life. As we look to the future, trends such as the integration of CFD with building information modeling, cloud-based simulations, and the use of machine learning promise to further enhance the capabilities of CFD in HVAC design. In a world increasingly focused on sustainability and energy efficiency, CFD is a vital tool that paves the way for more environmentally friendly and efficient HVAC solutions.