CFD Projects in the Automobile Industry: The automobile industry is constantly evolving, with a focus on enhancing performance, efficiency, and safety while reducing costs and environmental impact. One groundbreaking tool that has revolutionized the design and optimization process in this industry is Computational Fluid Dynamics, commonly known as CFD. In this article, we’ll delve into the significant role CFD projects play in the automobile sector and explore their applications, benefits, challenges, successful examples, and future trends.

read more : CFD Consulting Services

1. Introduction

Computational Fluid Dynamics (CFD) is a specialized branch of fluid mechanics that employs numerical methods and algorithms to analyze and solve complex fluid flow and heat transfer problems. CFD simulations allow engineers and researchers to visualize and understand how fluids, such as air and liquids, interact with various surfaces and structures. This knowledge is invaluable in designing and optimizing systems, and it has become a crucial tool in the automobile industry.

2. Understanding Computational Fluid Dynamics (CFD)

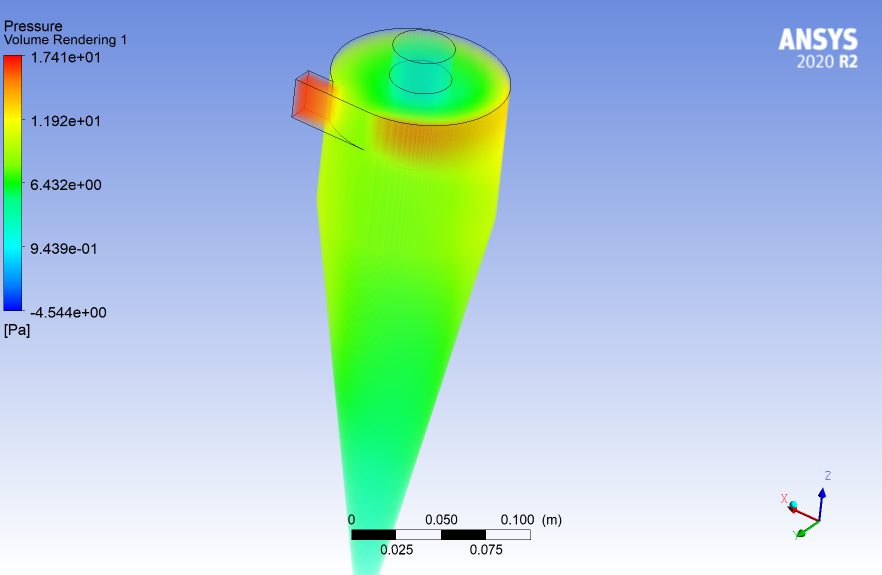

CFD involves creating a virtual representation of a physical system and applying mathematical equations to simulate the behavior of fluids within that system. By breaking down the fluid flow into small computational elements, CFD can provide detailed insights into factors like velocity, pressure, temperature distribution, and turbulence. This understanding is particularly important in the automobile industry, where aerodynamics, engine performance, and cooling systems heavily rely on fluid dynamics.

3. Applications of CFD in the Automobile Industry

3.1 Aerodynamics Optimization

One of the primary areas where CFD projects excel in the automobile industry is aerodynamics optimization. By simulating the airflow around a vehicle, engineers can identify areas of high drag and turbulence, leading to more streamlined designs. This not only improves fuel efficiency but also reduces wind noise and enhances stability at high speeds.

3.2 Engine Design and Efficiency

CFD plays a pivotal role in the design and optimization of internal combustion engines. It allows engineers to study combustion processes, optimize air-fuel mixing, and enhance thermal efficiency. This results in engines that deliver better performance while meeting stringent emissions standards.

3.3 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems in vehicles benefit from CFD simulations. Engineers can analyze the distribution of airflow, optimize duct designs, and ensure efficient temperature control within the vehicle’s interior. This leads to a more comfortable and energy-efficient driving experience.

4. Benefits of CFD Projects in the Automobile Industry

4.1 Cost and Time Savings

CFD simulations significantly reduce the need for expensive physical prototypes and testing. By conducting virtual experiments, manufacturers can iterate through design changes quickly, saving both time and money in the development process.

4.2 Improved Performance and Safety

CFD enables engineers to fine-tune vehicle designs, leading to better overall performance and safety. From reducing drag and increasing fuel efficiency to enhancing crashworthiness through aerodynamic improvements, CFD projects directly impact the quality and safety of automobiles.

4.3 Environmental Impact

CFD projects contribute to reducing the environmental footprint of the automobile industry. By optimizing fuel efficiency and emissions control, CFD helps develop eco-friendly vehicles that meet regulatory standards and address environmental concerns.

5. Challenges in CFD Projects for Automobiles

5.1 Complex Simulations

Simulating fluid dynamics in an automobile’s complex geometry requires sophisticated computational models and high-performance computing resources. Managing the complexity of these simulations while maintaining accuracy is a significant challenge.

5.2 Data Accuracy and Validation

CFD simulations depend on accurate input data and validation against real-world experiments. Ensuring that the simulation results align with physical reality is crucial for the reliability of CFD projects.

5.3 High Computational Resources

Performing detailed CFD simulations demands substantial computational resources. This includes powerful hardware and efficient software algorithms to handle the complex calculations involved.

6. Successful Examples of CFD Projects in the Automobile Industry

6.1 Vehicle Shape Optimization

Leading automotive companies utilize CFD to optimize vehicle shapes, reducing drag and improving fuel efficiency. This approach has led to innovative designs that balance aesthetics and aerodynamics.

6.2 Emissions Reduction

CFD helps in designing combustion systems that minimize emissions without compromising performance. This contributes to cleaner and more environmentally friendly vehicles.

6.3 Cooling System Design

Efficient cooling is essential for vehicle performance and longevity. CFD simulations assist in designing effective cooling systems that prevent overheating and ensure optimal engine operation.

7. Future Trends in CFD for Automobiles

As technology advances, we can expect even more sophisticated applications of CFD in the automobile industry. This includes real-time simulations for on-road performance, integration with AI for advanced design optimizations, and further advancements in energy-efficient vehicle design.

8. Conclusion

Computational Fluid Dynamics has become a cornerstone of innovation in the automobile industry. Its ability to analyze and optimize fluid behavior within vehicles has led to more efficient, safer, and environmentally conscious designs. While challenges persist, the benefits of CFD projects are undeniable, and they will continue to shape the future of the automobile sector.